Repair Manuals for other

Briggs & ledooStratton

Quality Starts With A Master Service Technician

Single Cylinder OHV Air-CooledEngines

All rights reserved

FORWARD

Copyright 2009 Briggs & Stratton Corporation

Engine Models

This Engine Repair Manual includes the following

SECTION 2 - Troubleshooting

1 2 3 4 5 6 7 8 9 10 11 12

SECTION 1 - Safety, Maintenance and Adjustments

Page

SECTION 1 - SAFETY, MAINTENANCE, AND ADJUSTMENTS

Hazard Symbols and Meanings

ENGINE SAFETY

Signal Words in Safety Messages

When testing for spark

Before performing adjustments or repairs

Explosion and fire could result

YOUR KEY TO THE WORLD’S FINEST ENGINES

BRIGGS & STRATTON NUMERICAL IDENTIFICATION SYSTEM

BRIGGS & STRATTON MODEL NUMBERING SYSTEM

High Altitude

ENGINE MAINTENANCE

Fuel and Oil Recommendations

Fuel must meet these requirements

Every 50 Hours or Annually

Maintenance Chart First 5 Hours

Every 8 Hours or Daily

Every 25 Hours or Annually

Assemble Flywheel Brake

Inspect Brake and Switches

Air Filter

Combustion Chamber

Figure Figure Figure

Figure Figure Figure

Inspection

Install

Snow Hood

Remove

NOTICE

Oil and Oil Filter

Spark Plug

NOTICE

Cooling System

Horizontal Models 110000, 120000,

ENGINE ADJUSTMENTS

Remote Controls

Remote Control Wire Travel

2.Move throttle lever to fast position

Top No Load Adjustment Vertical Models 97700,

Governor Adjustments

Static Adjustment

2.Place throttle in FAST position

Final Adjustment All Models

Initial Adjustment All Models

Adjust Valve Clearance

Vertical Models 110000, 120000 Early Production

SECTION 2 - TROUBLESHOOTING

OIL GARD SYSTEMS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49 ENGINE WILL NOT START - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49 ENGINE STARTS AND RUNS WITH LOW OIL

Engine Running

SYSTEMS CHECK

1 Check Ignition

Engine Stopped

Solenoid Plunger Test

Testing Fuel Shut Off Solenoid

Solenoid Wiring Test

2 Check Carburetion

Possible Causes for Poor Compression

3 Check Compression

DC Shunt

ELECTRICAL SYSTEMS

Equipment Used for Testing

Digital Multimeter

Possible Causes

Alternator System Diagnosis

Complaint

Alternator Identification

4.Dual Circuit Figure

1.0.5 Amp DC Only Figure

2.14 Volt AC Only Figure

3.3 Amp DC Only Figure

8.20 Amp DC Figure

6.5/9 Amp DC Figure

7.10/16 Amp DC Figure

3-AmpDC Only Alternator

Testing Alternator Output

Flywheel Identification

5 Amp DC Only Alternator

Test Diode

14-VoltAC Alternator

Test Alternator Output-DC

Dual Circuit Alternator

Test Alternator Output

Test Alternator Output-AC

Test Diode

Tri-CircuitAlternator

Test Diode

Charging Circuit Test RED Wire

Lighting Circuit Test WHITE Wire

Test Alternator Output

Test Regulator-Rectifier

5 & 9 Amp DC Regulated Alternator

Test Alternator Output

Test Regulator - Rectifier

10 & 16 Amp DC Regulated Alternator

Test Alternator Output

receptacle

2.Install shunt to negative -battery terminal

Test Alternator Output

DC Output Charging Wire Test

20 Amp DC Regulated Alternator

NOTICE

5.Rotate selector to DC volts position

Figure

Model Series 97700, 99700, 110000,

ELECTRIC STARTERS

SYSTEM 3, SYSTEM

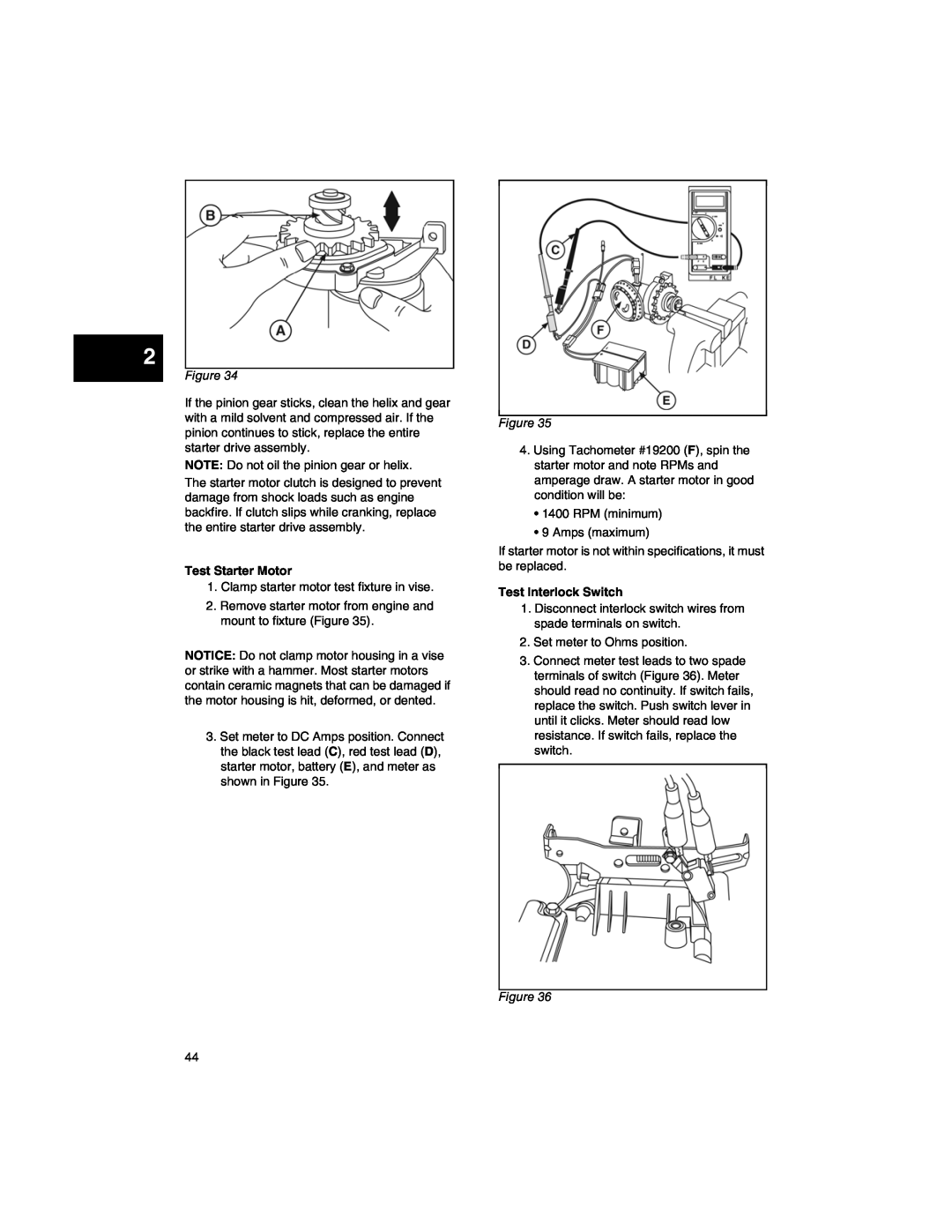

Test Starter Motor

Test Interlock Switch

Test Starter Motor

Test Interlock Switch Wiring

12 Volt DC Starter Motor

Test Solenoid

120-VoltAC Starter Motor

Model Series 120000, 150000, 200000,

Charging Battery

BATTERIES

Battery and Cable Recommendations

Battery Installation

Testing Battery

Engine Won’t Stop

EQUIPMENT AFFECTING ENGINE OPERATION

OIL GARD SYSTEMS

Hard Starting or Will Not Start

Engine Starts and Runs With Low Oil

On/Off Switch Light Does Not Flash

SECTION 3 - EXHAUST SYSTEMS

Remove Guard and Muffler

MUFFLER SERVICE

Spark Arresters

Horizontal Models 110000, 120000,

Inspect Exhaust System

Never reinstall broken or damaged components

Install Muffler and Guard

3.Remove muffler support screws A, Figure

Horizontal Models 200000,

Shown is a typical muffler application Figure

Remove Guard and Muffler

All exhaust system components must be inspected whenever the exhaust system is disassembled. Check muffler mounting bracket and/or muffler adapters for cracked welds or breakage. Check muffler for split seams, loose internal parts, or cracked welds. Replace any damaged parts with new OEM parts

Never reinstall broken or damaged components

Install Muffler and Guard

Inspect Exhaust System

Inspect Exhaust System

Never reinstall broken or damaged components

Install Muffler and Guard

Vertical Models 97700, 99700, 110000,

components

Never reinstall broken or damaged

Install Muffler and Guard

Inspect Exhaust System

Inspect Exhaust System

Never reinstall broken or damaged components

Remove Muffler

Install Muffler

Remove Muffler

Never reinstall broken or damaged components

Install Muffler

Shown is a typical muffler application Figure

SECTION 4 - FUEL SYSTEMS AND CARBURETION

FUEL SYSTEMS

Inspection

Installation

Fuel Pump

Removal

Removal

Fuel Filter

Fuel Tanks and Shut-offValves

Horizontal Models 110000, 120000, 150000, 200000,

Vertical Model

Installation

Installation

Vertical Models 97700, 99700, 110000,

2.Inspect fuel tank for •Corrosion •Leaks

Installation

Inspection

Carburetor Identification

CARBURETION

Remove Carburetor

Carburetor Service LMS Carburetor

Vertical Models 97700, 99700, 110000,

Disassemble Carburetor

Assemble Carburetor

Inspect and Clean Carburetor Components

Install Carburetor

Remove Carburetor

LMS Carburetor Horizontal Models 110000, 120000,

Assemble Carburetor

Inspect and Clean Carburetor Components

Disassemble Carburetor

•Passages in the fixed main jet bowl nut

edge of the plug with a non-hardeningsealant

Remove Carburetor

Install Carburetor

ReadyStart Carburetor Vertical Model

Assemble Carburetor

Inspect and Clean Carburetor

Disassemble Carburetor

LMT Carburetor

Disassemble Carburetor

Remove Carburetor

3.Move clamp and disconnect hose from carburetor

Assemble Carburetor

Inspect and Clean Carburetor

Page

bracket.4

Install Carburetor

Disassemble Carburetor

Nikki Carburetor Vertical Models 280000, 310000,

Remove Carburetor

11.Remove the main jet and seal

Inspect and Clean Carburetor

Assemble Carburetor

•Choke shaft and choke valve

Install Carburetor

12.Install new o-ringon fuel transfer tube E

Vertical Model 310000 Gaseous Fuel

Nikki LP/NG Mixer

SECTION 5 - GOVERNOR SYSTEMS

Linkage and Spring Orientation

GOVERNOR SYSTEMS

Disassemble

Governor Service

Governed RPM Limits

Horizontal Models 110000, 120000, 150000, 200000,

Assemble

Inspect Governor

Assemble Governor

Disassemble

Inspect Governor

8. Adjust governor system per Section

SECTION 6 - CYLINDER HEAD AND VALVES

Remove Cylinder Head

CYLINDER HEADS AND VALVES

Inspection

Disassemble Cylinder Head

Assemble Cylinder Head

Install Cylinder Head

NOTE: Do not torque each screw in one step as it may result in a warped cylinder head. Step- torque all screws to approximately 1/3 of final torque value, then to 2/3 final torque value, then finish at final torque value

Inspection

Remove Cylinder Head

Models 200000, 210000, 280000, 310000,

Disassemble Cylinder Head

Assemble Cylinder Head

mm or more, replace the entire head. If plug gauge is not available, see Section 12 - Engine Specifications for the valve guide reject dimension

Install Cylinder Head

4.Install push rods through guides and into same positions as removed. Ensure rods are seated in valve tappets. Place valve stem caps if used on valve stems Figure

Page

SECTION 7 - STARTERS

Vertical Models 97700,

REWIND STARTERS

Remove Blower Housing / Rewind Starter

Horizontal Models 110000, 120000, 150000, 200000,

Vertical Models 110000,

Disassemble Rewind Starter

Service Rewind Starter

Vertical Model

Assemble Rewind Starter

Inspect Rewind Starter Parts

Vertical Models 110000,

2.Install the oil fill tube and dipstick C

Vertical Models 97700,

Inspect Clutch Parts

Service Starter Clutch

Vertical Model

Disassemble Starter Clutch

Check Starter Drive and Clutch

ELECTRIC STARTERS

Replace Ring Gear

System 3, System

Check Starter Drive and Clutch

Install Starter Drive and Clutch

12 Volt Starters

Remove Starter Drive and Clutch

Assemble Starter Motor Drive - C-Ring Retainer

Disassemble Starter Drive - Roll Pin Retainer

Assemble Starter Drive - Roll Pin Retainer

120-VoltStarters

SECTION 8 - LUBRICATION SYSTEMS

Horizontal Models 110000, 120000,

EXTENDED OIL FILL AND DIPSTICK

BREATHERS

Install Breather

Remove Breather

3.Inspect oil drain-backholes C, Figure 3 to make sure they are open. Clean as needed

Install Breather

Check Breather

Check Breather

Install Breather

8Current Production

Remove Breather

Oil Slinger Lubrication

LUBRICATION SYSTEMS

Install Breather

Oil Dipper Lubrication

Vertical Models 120000, 210000, 280000, 310000,

Oil Pump Service

Oil Slinger with Pressure Filtration

Pressure Lubrication

Remove Pump Screen

Oil Filter and Adapters Remove

Install Screen and Gerotor Pump

Inspect Oil Pump Parts

Oil Gard Systems

Oil Pressure Switch

Install

Test Oil Pressure Switch

Identification

Lead Wire Colors

Lead Wire Colors

Troubleshooting

SECTION 9 - CYLINDERS, COVERS AND SUMPS

Resizing Bore

CYLINDER

Inspect Cylinder

Reconditioning Bore

Check Plain Bearings

MAIN BEARINGS

Cleaning Cylinder

Check Bearings

PTO Bearing Tools

Replace Bearings

Replace DU Bearings

Magneto Bearing Tools

Replace Ball Bearing Horizontal Models 120000,

Tool/Part

Bearing Installation Tools

Replace Ball Bearing Horizontal Models 200000,

Bearing Removal Tools

Replace Ball Bearing All Vertical Models

Installation

COVERS AND SUMPS

Figure

Figure Figure

Page

SYSTEMS, AND GEAR REDUCTIONS

SECTION 10 - CRANKSHAFTS, CAMSHAFTS, BALANCING

Check Crankshaft

CRANKSHAFTS AND CAMSHAFTS

Remove Crankshaft and Camshaft

Inspect

Install Crankshaft and Camshaft

Install Crankcase Cover or Sump

Check and Adjust Crankshaft End Play

Inspect Gear Reduction Parts

GEAR REDUCTION

Disassemble Gear Reduction

Assemble Gear Reduction

Fill Gear Case with Lubricant

Assemble Auxiliary PTO Drive Shaft

AUXILIARY PTO

Inspection

Remove Auxiliary PTO Drive Shaft

Remove Counterbalance System

COUNTERBALANCE SYSTEMS

Synchro-BalanceSystem

Disassemble

Assemble

Install

Disassemble

Install

AVS Balance System

Remove

Page

SECTION 11 - PISTONS, RINGS AND CONNECTING RODS

Inspect

PISTONS, RINGS, & CONNECTING RODS

Remove Piston and Connecting Rod

Disassemble

Check Ring End Gap

Check Connecting Rod

Assemble

Install Piston and Connecting Rod

SECTION 12 - ENGINE SPECIFICATIONS

TORQUE

MODEL 110000 HORIZONTAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

REJECT DIMENSIONS

TORQUE

MODEL 120000 HORIZONTAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

Main Bearing

TORQUE

MODEL 150000 HORIZONTAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

REJECT DIMENSIONS

TORQUE

MODEL 200000 HORIZONTAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

Main Bearing

TORQUE

MODEL 210000 HORIZONTAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

Main Bearing

TORQUE

MODELS 97700 & 99700 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

REJECT DIMENSIONS

TORQUE

MODEL 110000 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

REJECT DIMENSIONS

TORQUE

MODEL 120000 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

REJECT DIMENSIONS

TORQUE

MODEL 210000 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

REJECT DIMENSIONS

TORQUE

MODEL 280000 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

Main Bearing

TORQUE

MODEL 310000 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

Main Bearing

TORQUE

MODEL 330000 VERTICAL SERIES

ENGINE SPECIFICATIONS

FASTENER TORQUE SPECIFICATIONS

Main Bearing