1. ERROR INDICATION

To help the user or the service personnel promptly locate the cause of a problem (if any), the facsimile equipment incorporates the

For the communications errors, the equipment also prints out the transmission verification report and the communications list.

1.1Equipment Errors

If an equipment error occurs, the facsimile equipment emits an audible alarm (continuous beeping) for approximately 4 seconds and shows the error message on the LCD. For the error messages, see [ 1 ] below. As one of the error messages, “MACHINE ERROR _ _” includes an error code which indicates the detailed error causes listed in [ 2 ].

To display an error code for the other latest error message or detailed message, make the equipment enter the maintenance mode and press 8 and 2 keys (for details, refer to Chapter V, Section 3.12).

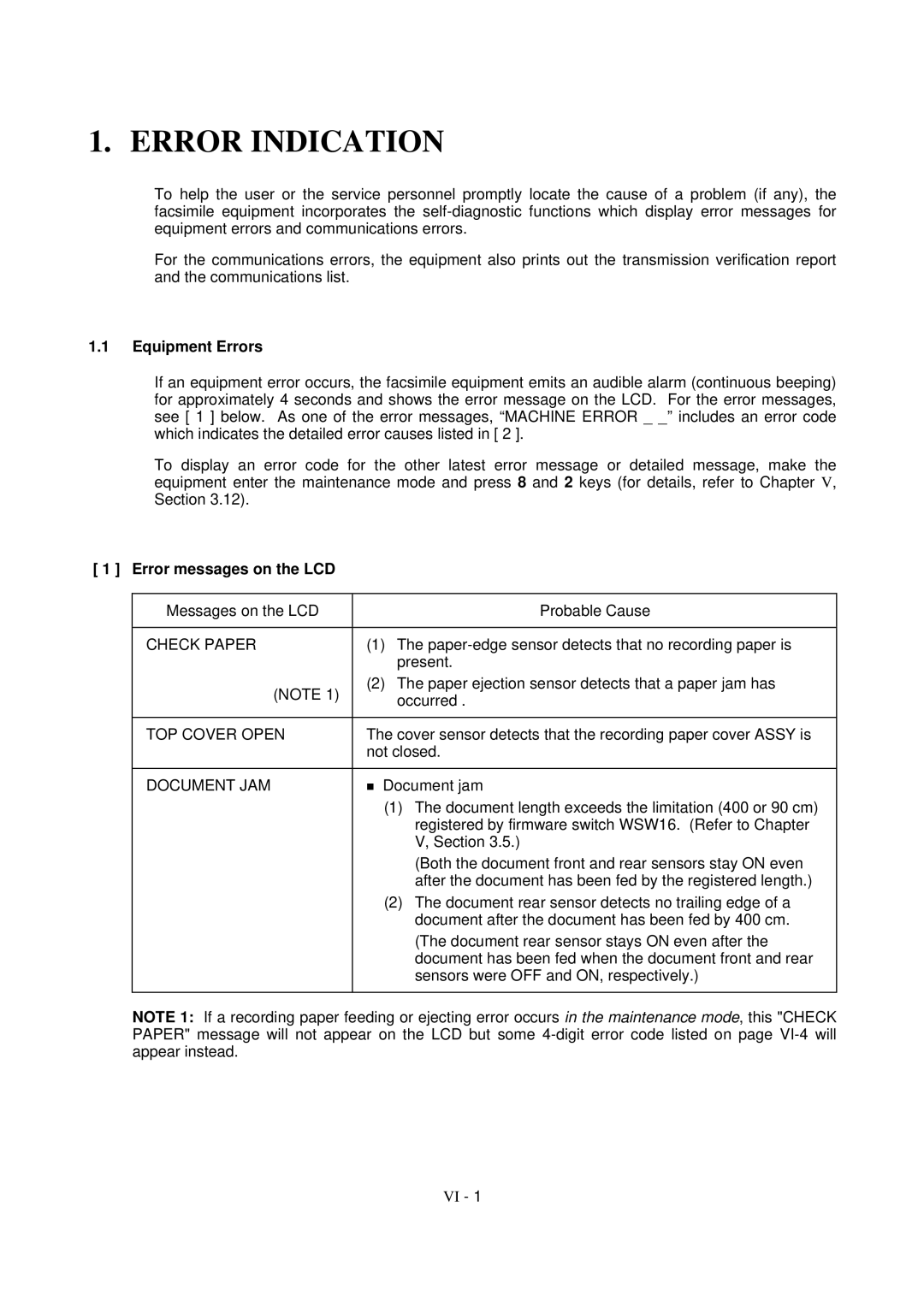

[ 1 ] Error messages on the LCD

Messages on the LCD | Probable Cause | |

|

| |

CHECK PAPER | (1) The | |

| present. | |

(NOTE 1) | (2) The paper ejection sensor detects that a paper jam has | |

occurred . | ||

| ||

|

| |

TOP COVER OPEN | The cover sensor detects that the recording paper cover ASSY is | |

| not closed. | |

|

| |

DOCUMENT JAM | n Document jam | |

| (1) The document length exceeds the limitation (400 or 90 cm) | |

| registered by firmware switch WSW16. (Refer to Chapter | |

| V, Section 3.5.) | |

| (Both the document front and rear sensors stay ON even | |

| after the document has been fed by the registered length.) | |

| (2) The document rear sensor detects no trailing edge of a | |

| document after the document has been fed by 400 cm. | |

| (The document rear sensor stays ON even after the | |

| document has been fed when the document front and rear | |

| sensors were OFF and ON, respectively.) | |

|

|

NOTE 1: If a recording paper feeding or ejecting error occurs in the maintenance mode, this "CHECK PAPER" message will not appear on the LCD but some

VI - 1