30RY/RYH, 30RA/RH specifications

The Carrier 30RY/RYH and 30RA/RH chiller models are leading solutions in commercial and industrial cooling applications. Renowned for their reliability, efficiency, and advanced technologies, these chillers cater to a wide variety of settings, from office buildings to manufacturing facilities.The 30RY/RYH series features a distinctive design optimized for performance, utilizing a centrifugal compressor that ensures smooth operation under varying loads. One of the standout features of these chillers is their high-efficiency capabilities, which contribute to lower energy consumption. The models are engineered to deliver substantial energy savings, meeting or exceeding the latest ASHRAE and DOE efficiency standards.

A significant aspect of the 30RY and 30RA models is their use of environmentally friendly refrigerants. The 30RYH, for instance, employs R-134a refrigerant, which is designed to minimize ozone depletion while maximizing efficiency. This commitment to sustainability aligns with modern environmental regulations and practices, making these chillers a wise choice for eco-conscious projects.

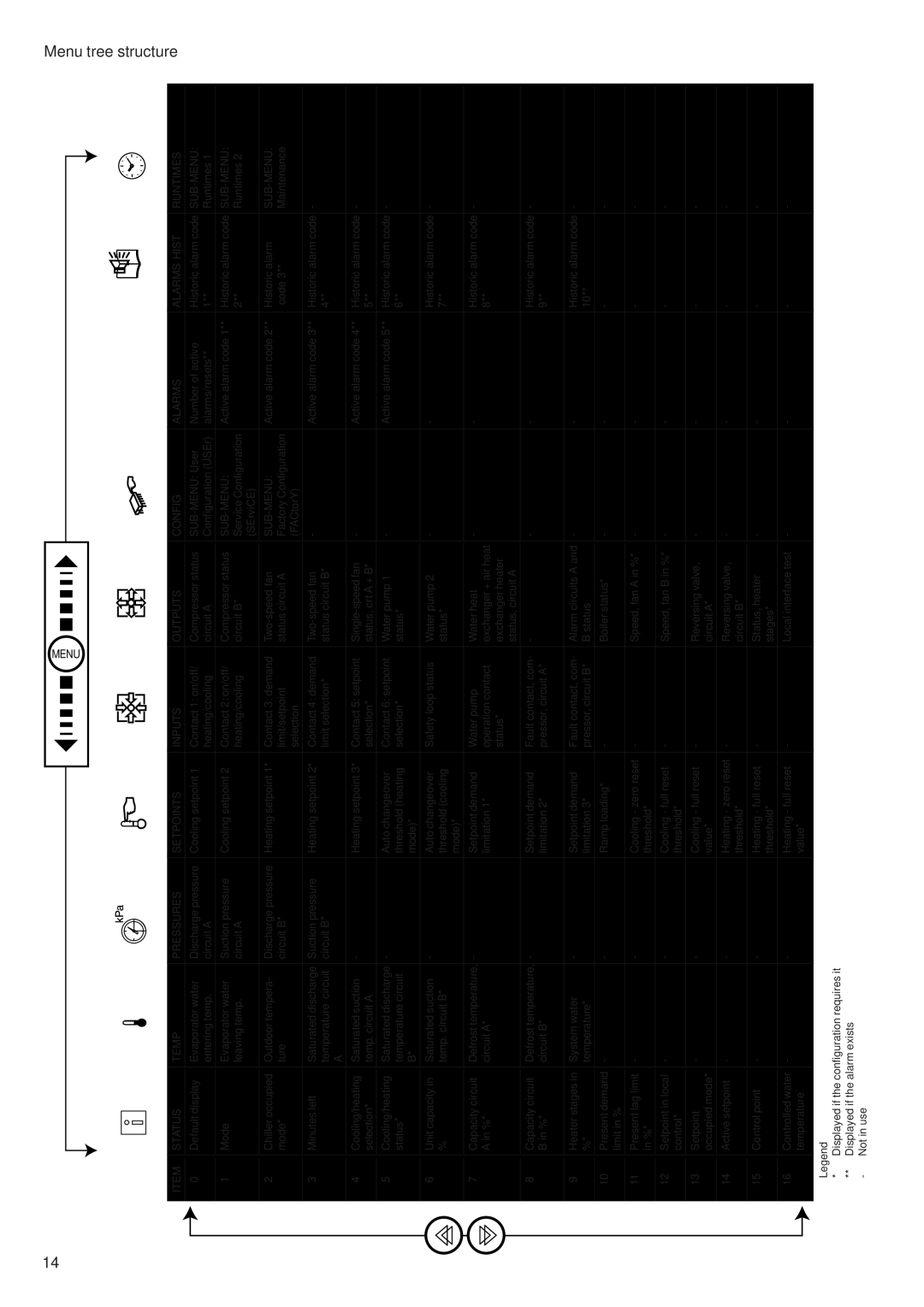

In terms of control technology, the chiller models come equipped with advanced microprocessor-based controls, providing users with optimal system management and diagnostics. This integrated control system enhances the overall performance and reliability of the chillers, allowing for real-time monitoring and adjustment to ensure peak operational efficiency.

Another key feature is the quiet operation of the 30RY/RYH and 30RA/RH series. Designed with sound attenuation in mind, these units minimize noise pollution, making them suitable for installations in noise-sensitive environments. Additionally, the modular design allows for easy installation and maintenance, reducing downtime and providing flexibility in system design.

Both series also offer robust thermal performance, with the capability to handle a wide range of operating conditions. The chillers excel in terms of cooling capacity, providing solutions for varying thermal loads while maintaining energy efficiency. This adaptability is invaluable for facilities managing seasonal changes in cooling demands.

In summary, the Carrier 30RY/RYH and 30RA/RH chillers represent an ideal blend of efficiency, advanced technology, and eco-friendliness. Their high-performance capabilities, user-friendly controls, and sustainable design make them a top choice for commercial and industrial applications, ensuring dependable cooling solutions for diverse environments.