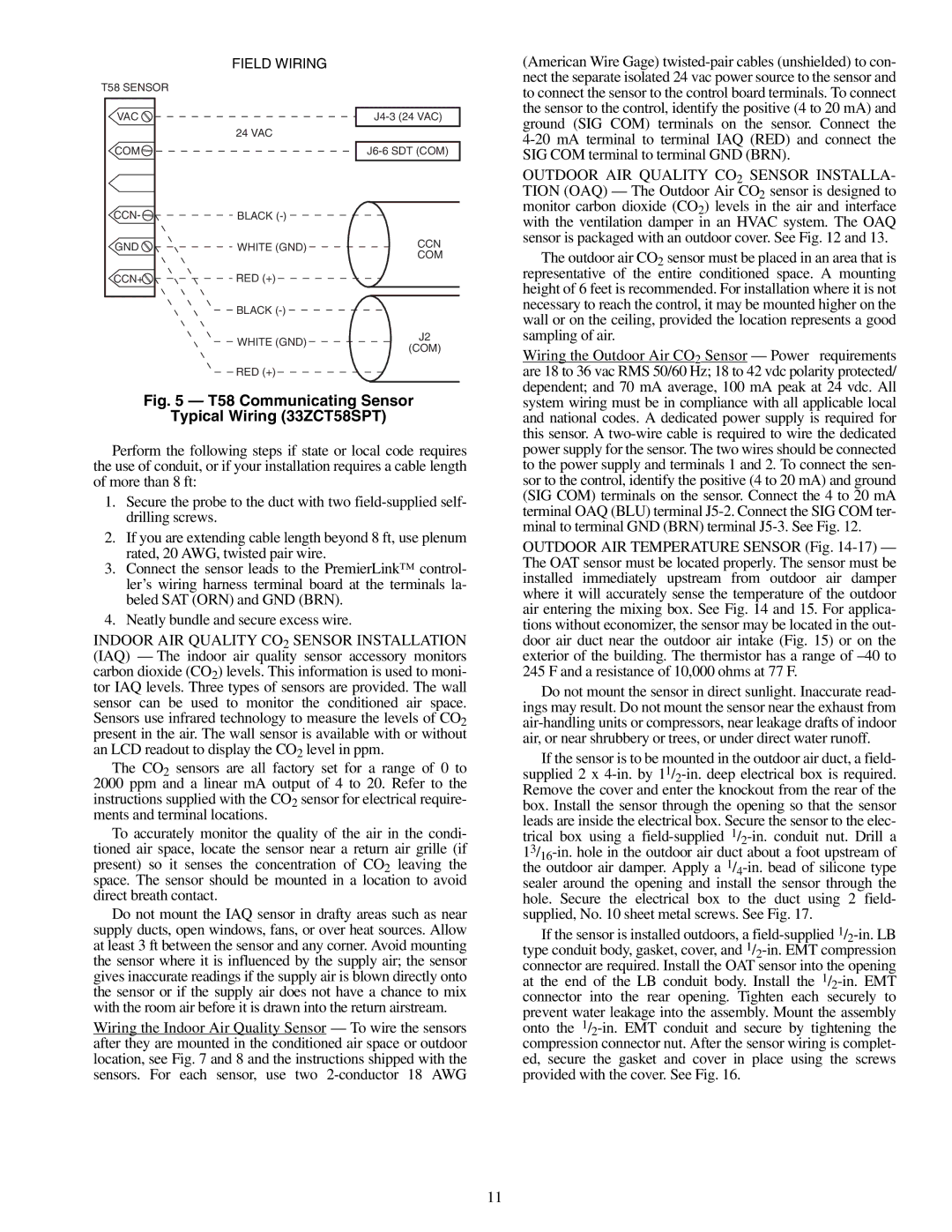

FIELD WIRING

(American Wire Gage)

T58 SENSOR

VAC ![]()

24 VAC

COM![]()

![]()

GND | WHITE (GND) |

CCN+ | RED (+) |

| BLACK |

CCN

COM

to connect the sensor to the control board terminals. To connect the sensor to the control, identify the positive (4 to 20 mA) and ground (SIG COM) terminals on the sensor. Connect the

OUTDOOR AIR QUALITY CO2 SENSOR INSTALLA- TION (OAQ) — The Outdoor Air CO2 sensor is designed to monitor carbon dioxide (CO2) levels in the air and interface with the ventilation damper in an HVAC system. The OAQ sensor is packaged with an outdoor cover. See Fig. 12 and 13.

The outdoor air CO2 sensor must be placed in an area that is representative of the entire conditioned space. A mounting height of 6 feet is recommended. For installation where it is not necessary to reach the control, it may be mounted higher on the wall or on the ceiling, provided the location represents a good

WHITE (GND) | J2 | |

(COM) | ||

| ||

RED (+) |

|

Fig. 5 — T58 Communicating Sensor

Typical Wiring (33ZCT58SPT)

Perform the following steps if state or local code requires the use of conduit, or if your installation requires a cable length of more than 8 ft:

1.Secure the probe to the duct with two

2.If you are extending cable length beyond 8 ft, use plenum rated, 20 AWG, twisted pair wire.

3.Connect the sensor leads to the PremierLink™ control- ler’s wiring harness terminal board at the terminals la- beled SAT (ORN) and GND (BRN).

4.Neatly bundle and secure excess wire.

INDOOR AIR QUALITY CO2 SENSOR INSTALLATION (IAQ) — The indoor air quality sensor accessory monitors carbon dioxide (CO2) levels. This information is used to moni- tor IAQ levels. Three types of sensors are provided. The wall sensor can be used to monitor the conditioned air space. Sensors use infrared technology to measure the levels of CO2 present in the air. The wall sensor is available with or without an LCD readout to display the CO2 level in ppm.

The CO2 sensors are all factory set for a range of 0 to 2000 ppm and a linear mA output of 4 to 20. Refer to the instructions supplied with the CO2 sensor for electrical require- ments and terminal locations.

To accurately monitor the quality of the air in the condi- tioned air space, locate the sensor near a return air grille (if present) so it senses the concentration of CO2 leaving the space. The sensor should be mounted in a location to avoid direct breath contact.

Do not mount the IAQ sensor in drafty areas such as near supply ducts, open windows, fans, or over heat sources. Allow at least 3 ft between the sensor and any corner. Avoid mounting the sensor where it is influenced by the supply air; the sensor gives inaccurate readings if the supply air is blown directly onto the sensor or if the supply air does not have a chance to mix with the room air before it is drawn into the return airstream.

Wiring the Indoor Air Quality Sensor — To wire the sensors after they are mounted in the conditioned air space or outdoor location, see Fig. 7 and 8 and the instructions shipped with the sensors. For each sensor, use two

sampling of air.

Wiring the Outdoor Air CO2 Sensor — Power requirements are 18 to 36 vac RMS 50/60 Hz; 18 to 42 vdc polarity protected/ dependent; and 70 mA average, 100 mA peak at 24 vdc. All system wiring must be in compliance with all applicable local and national codes. A dedicated power supply is required for this sensor. A

OUTDOOR AIR TEMPERATURE SENSOR (Fig.

Do not mount the sensor in direct sunlight. Inaccurate read- ings may result. Do not mount the sensor near the exhaust from

If the sensor is to be mounted in the outdoor air duct, a field- supplied 2 x

If the sensor is installed outdoors, a

11