48FK,JK034-074 50FK,FY,JK,JY034-104 Variable-Air Volume Rooftop Units

Controls Operation and Troubleshooting

SAFETY CONSIDERATIONS

CONTENTS cont

GENERAL

Return-Air Temperature

Table 1 Ð Pin Terminal Connector J1 Thermistor Inputs

Fig. 1 Ð Processor Board

Table 2 Ð Pin Terminal Connector J2 Status Switch Inputs

Fig. 3 Ð Pin Terminal Connector J2

Status Switch Inputs

Fig. 2 Ð Pin Terminal Connector J1 Thermistor Inputs

The potentiometer locations and functions are as follows

Fig. 5 Ð Relay Board

Table 3 Ð Output Pin and Terminal Assignments

Compressor Operation

48FK,JK ONLY

Fig. 8 Ð Thermistor T1 Location, 50FK,JK034-048 Units

GAS SECTION

HORIZONTAL SUPPLY SECTION

GAS SECTION

Fig. 9 Ð Thermistor T1 Location, 48FK,JK, 50JY and

50JKX,JKY 054-074 Units and 50FKX,FKY and 50FY054-104 Units

Fig. 10 Ð Thermistor T1 Location, 50FK,JK054-074 Units

STANDARD

Fig. 11 Ð Thermistor T2 Location, Size 034-048 Units

Fig. 12 Ð Thermistor T2 Location, Size 054-104 Units

Fig. 13 Ð Thermistor T3 and T4 Locations Size 034-048 Units

054 UNITS 064, 074, 078 UNITS 088, 104 UNITS

Fig. 14 Ð Thermistor T3 and T4 Locations, Size 054-104 Units

Fig. 18 Ð Variable Frequency Drive Sizes 034-048 and

Fig. 15 Ð Accessory Relay Board Standard Factory Supplied

Fig. 16 Ð Two-Step Demand Limit Module

Fig. 17 Ð Enthalpy Sensor Location

Space Temperature Reset

CONTROLS INSTALLATION

Fig. 20 Ð Unit Control Box Arrangement, Sizes

Fig. 21 Ð Unit Control Box Arrangement, Sizes

Fig. 22 Ð Unit Control Box Arrangement, Sizes 088 and

Fig. 24 Ð Heat Interlock Relay

Fig. 23 Ð Occupied/Unoccupied Switch with Night Setback Thermostat

Fig. 25 Ð Accessory Reset Board

Voltage Drop Characteristics

Fig. 26 Ð Space Temperature Sensor Averaging

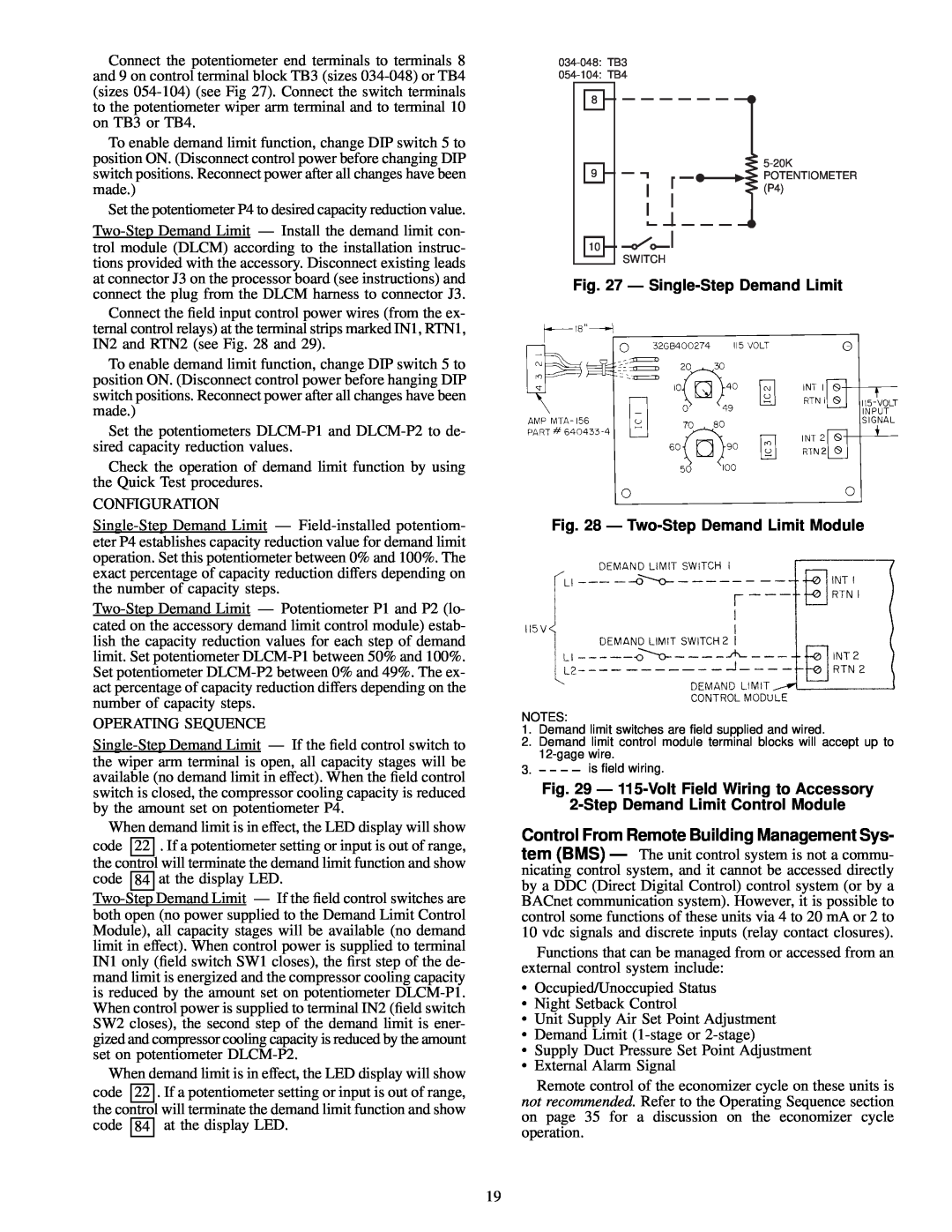

2-Step Demand Limit Control Module

Fig. 29 Ð 115-Volt Field Wiring to Accessory

Fig. 27 Ð Single-Step Demand Limit

Fig. 28 Ð Two-Step Demand Limit Module

This emulation requires the following eld-supplied parts

R Ð Resistor Factory Installed Factory Wiring Field Wiring

Fig. 30 Ð Remote SASP Wiring

Fig. 31 Ð External Alarm Indication

P Ð Manual Potentiometer R Ð Fixed Resistor Field Wiring

Fire

Table 6 Ð Smoke Control Switches Required for Each Mode

Modulating Power

Table 5 Ð Smoke Control Modes

SIZE in

Table 7 Ð Switch Functions

Modulating Power Exhaust

Table 8 Ð Tubing Size

034-048 UNITS

Fig. 32 Ð Smoke Control Wiring

ALL UNITS

Fig. 35 Ð Modulating Power Exhaust Differential Pressure Switch Sizes

Fig. 33 Ð Modulating Power Exhaust and Inlet

Guide Vane Differential Pressure Switch Sizes

Pressure Switch and Variable Frequency Drive

Table 9 Ð Potentiometer Inputs and Ranges

Table 10 Ð Conguration Header and DIP Switch Factory Settings

Table 11 Ð Conguration Header Jumpers

Table 12 Ð DIP Switches

Size 078-104 Units

Fig. 36 Ð Inlet Guide Vane Motor 50FK,JK034-074 Units

Fig. 37 Ð Inlet Guide Vane Motor, 48FK,JK, 50FY,JY

and 50FJX,FJY,FKX,FKY034-074 Units Fig. 38 Ð Inlet Guide Vane Motor

Fig. 41 Ð Jumper Removal to Disable Motor

READ STOP WRITE RESET

Fig. 39 Ð Differential Pressure Switch for Inlet Guide

Modulating Power Exhaust Option

Table 13 Ð VFD Set Point Frequency Command for Duct Pressure

Modulating Power Exhaust Option or Acces

Table 14 Ð Changing the VFD Set Point Frequency Command

START UNIT

NORMAL

Table 15 Ð Quick Test, Unit Conguration and Switch Check

CONTROL SWITCH

QUICK

Table 17 Ð Quick Test, Output Relay Check

Table 16 Ð Quick Test, Thermistor and Potentiometer Check

Table 18 Ð Sensor Resistance Values

OPERATING INFORMATION

warm-up routine, and a 26 will be displayed

034 AND 038 UNITS

Fig. 42 Ð Component Arrangement, 034-048 Units

044 AND 048 UNITS

088, 104 UNITS 104 UNITS

Fig. 43 Ð Component Arrangement, 054-104 Units

054, 064 UNITS

074, 078 UNITS

Supply Fan Control with IGV Ð In most VAV units, the supply fan static pressure is controlled by inlet guide vanes. The inlet guide vanes operate independently from the micro- processor. The supply static pressure is controlled by a dif- ferential pressure switch. If the unit is equipped with a re- turn fan, building pressure is controlled by another differential pressure switch

Fig. 44 Ð Modulating Power Exhaust Component Locations Sizes

Fig. 45 Ð Modulating Power Exhaust Component Locations Sizes

Page

Table 19 Ð Compressor Loading and Unloading Sequences

Table 19 Ð Compressor Loading and Unloading Sequences cont

Table 20 Ð Controls Troubleshooting

TROUBLESHOOTING

Table 21 Ð Operation Status Codes

Table 22 Ð Diagnostic Codes

ergize alarm light and cause an error code of 83 to be dis

· Wiring Problem Ð If the circuit is open, a failure will be detected

82 to be displayed on display board when display button is

will be energized and an error code of 82 will be displayed

Page

Fig. 49 Ð Relay Board Test Points

Fig. 48 Ð Processor Board Test Points

Fig. 51 Ð Display Board Pin Terminal Connector J10

Fig. 50 Ð Relay Board Pin Terminal Connector J9

Table 23 Ð Voltage Reading

Step 2 Ð High-voltage relay resistance check

Table 24 Ð Pin Terminal Connector J1 Voltages

Table 25 Ð Pin Terminal Connector J2 Voltages

Step 1 Ð Low-voltage relay resistance check

Table 28 Ð Enthalpy Sensor Checkout

Table 27 Ð Terminal Strip J5 Connector Resistance Reading

1. Disconnect all power to the unit and the VFD

Fig. 52 Ð Damper Motor Connection Diagram VAV

Variable Frequency Drive

Gr.SF

Table 29 Ð Carrier Default Program Parameter Values

Frequency Settings

Gr.Fb

Fig. 54 Ð Variable Frequency Drive Terminal Block Size 054-104 Units

Table 30 Ð Required User Adjusted Defaults

Table 31 Ð Motor Overload Settings

Fig. 53 Ð Variable Frequency Drive Terminal Block Size 034-048 Units

LEGEND AND NOTES FOR FIG

Page

Page

CALL FOR FREE CATALOG

SERVICE TRAINING

I. PRE-START-UP

START-UP CHECKLIST

II. PRELIMINARY CHECKLIST ITEMS

CONTROL SETTINGS

ELECTRICAL

TEMPERATURES

III. START-UP

IV. NOTES

![]()

![]()