Diagnostic Codes Ð Diagnostic codes are warnings of abnormal or fault conditions, and may cause either one circuit or the whole unit to shut down. They are assigned code numbers as described below.

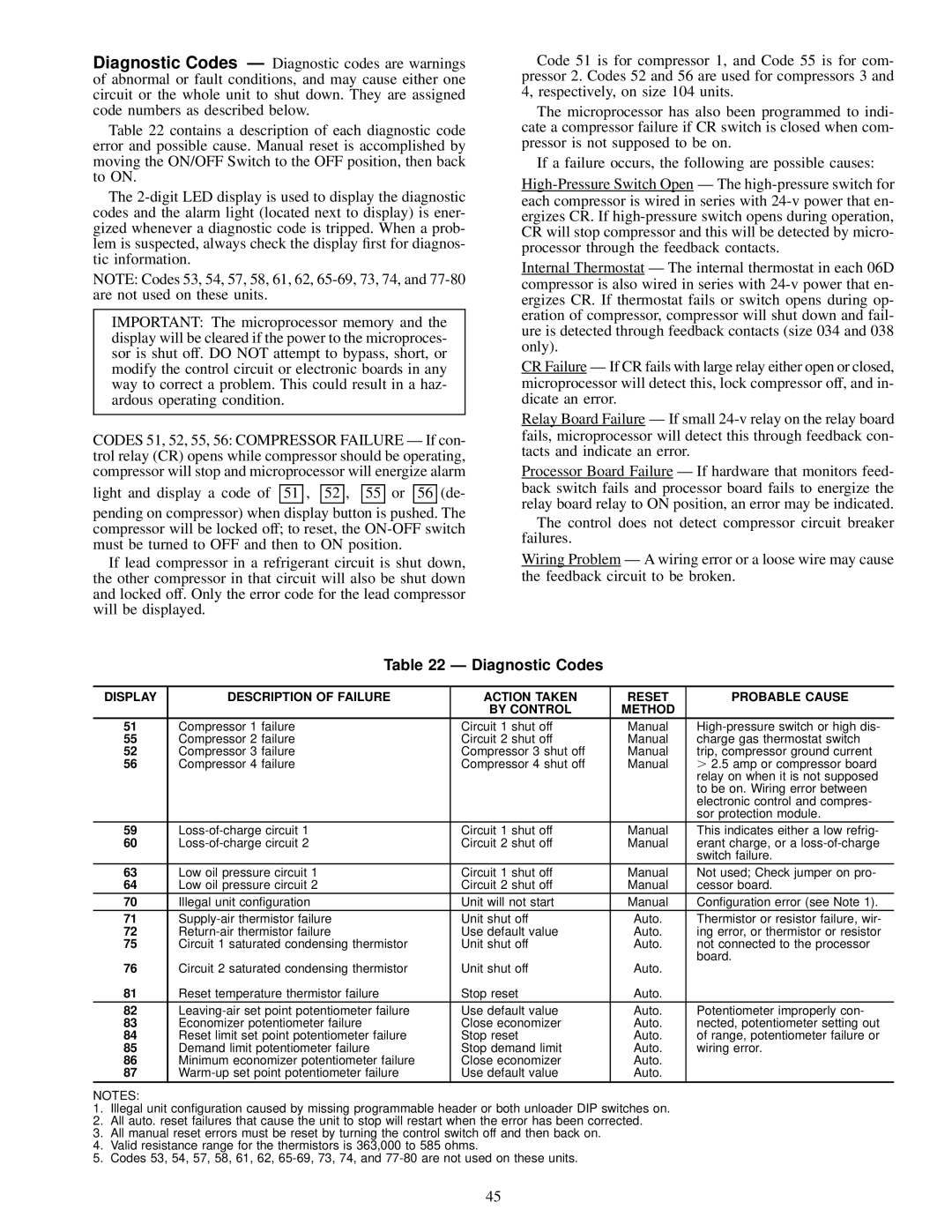

Table 22 contains a description of each diagnostic code error and possible cause. Manual reset is accomplished by moving the ON/OFF Switch to the OFF position, then back to ON.

The

NOTE: Codes 53, 54, 57, 58, 61, 62,

IMPORTANT: The microprocessor memory and the display will be cleared if the power to the microproces- sor is shut off. DO NOT attempt to bypass, short, or modify the control circuit or electronic boards in any way to correct a problem. This could result in a haz- ardous operating condition.

CODES 51, 52, 55, 56: COMPRESSOR FAILURE Ð If con- trol relay (CR) opens while compressor should be operating, compressor will stop and microprocessor will energize alarm

light and display a code of 51 , 52 , 55 or 56 (de-

pending on compressor) when display button is pushed. The compressor will be locked off; to reset, the

If lead compressor in a refrigerant circuit is shut down, the other compressor in that circuit will also be shut down and locked off. Only the error code for the lead compressor will be displayed.

Code 51 is for compressor 1, and Code 55 is for com- pressor 2. Codes 52 and 56 are used for compressors 3 and 4, respectively, on size 104 units.

The microprocessor has also been programmed to indi- cate a compressor failure if CR switch is closed when com- pressor is not supposed to be on.

If a failure occurs, the following are possible causes:

Internal Thermostat Ð The internal thermostat in each 06D compressor is also wired in series with

CR Failure Ð If CR fails with large relay either open or closed, microprocessor will detect this, lock compressor off, and in- dicate an error.

Relay Board Failure Ð If small

Processor Board Failure Ð If hardware that monitors feed- back switch fails and processor board fails to energize the relay board relay to ON position, an error may be indicated.

The control does not detect compressor circuit breaker failures.

Wiring Problem Ð A wiring error or a loose wire may cause the feedback circuit to be broken.

Table 22 Ð Diagnostic Codes

DISPLAY | DESCRIPTION OF FAILURE | ACTION TAKEN | RESET | PROBABLE CAUSE |

|

| BY CONTROL | METHOD |

|

51 | Compressor 1 failure | Circuit 1 shut off | Manual | |

55 | Compressor 2 failure | Circuit 2 shut off | Manual | charge gas thermostat switch |

52 | Compressor 3 failure | Compressor 3 shut off | Manual | trip, compressor ground current |

56 | Compressor 4 failure | Compressor 4 shut off | Manual | . 2.5 amp or compressor board |

|

|

|

| relay on when it is not supposed |

|

|

|

| to be on. Wiring error between |

|

|

|

| electronic control and compres- |

|

|

|

| sor protection module. |

59 | Circuit 1 shut off | Manual | This indicates either a low refrig- | |

60 | Circuit 2 shut off | Manual | erant charge, or a | |

|

|

|

| switch failure. |

63 | Low oil pressure circuit 1 | Circuit 1 shut off | Manual | Not used; Check jumper on pro- |

64 | Low oil pressure circuit 2 | Circuit 2 shut off | Manual | cessor board. |

70 | Illegal unit con®guration | Unit will not start | Manual | Con®guration error (see Note 1). |

71 | Unit shut off | Auto. | Thermistor or resistor failure, wir- | |

72 | Use default value | Auto. | ing error, or thermistor or resistor | |

75 | Circuit 1 saturated condensing thermistor | Unit shut off | Auto. | not connected to the processor |

76 | Circuit 2 saturated condensing thermistor | Unit shut off | Auto. | board. |

| ||||

81 | Reset temperature thermistor failure | Stop reset | Auto. |

|

82 | Use default value | Auto. | Potentiometer improperly con- | |

83 | Economizer potentiometer failure | Close economizer | Auto. | nected, potentiometer setting out |

84 | Reset limit set point potentiometer failure | Stop reset | Auto. | of range, potentiometer failure or |

85 | Demand limit potentiometer failure | Stop demand limit | Auto. | wiring error. |

86 | Minimum economizer potentiometer failure | Close economizer | Auto. |

|

87 | Use default value | Auto. |

|

NOTES:

1.Illegal unit con®guration caused by missing programmable header or both unloader DIP switches on.

2.All auto. reset failures that cause the unit to stop will restart when the error has been corrected.

3.All manual reset errors must be reset by turning the control switch off and then back on.

4.Valid resistance range for the thermistors is 363,000 to 585 ohms.

5.Codes 53, 54, 57, 58, 61, 62,

45