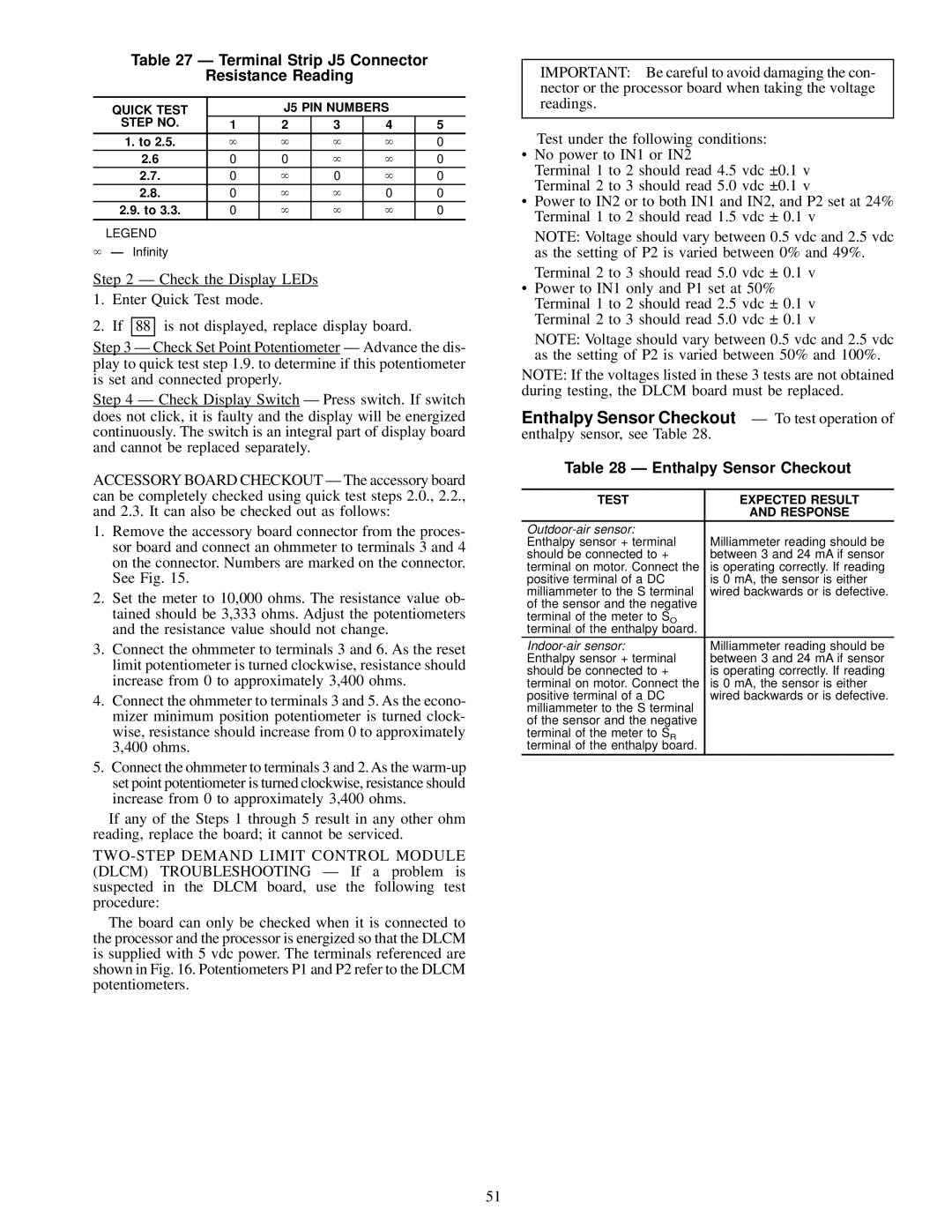

Table 27 Ð Terminal Strip J5 Connector

Resistance Reading

QUICK TEST |

| J5 PIN NUMBERS |

| ||

STEP NO. | 1 | 2 | 3 | 4 | 5 |

1. to 2.5. | ` | ` | ` | ` | 0 |

2.6 | 0 | 0 | ` | ` | 0 |

2.7. | 0 | ` | 0 | ` | 0 |

2.8. | 0 | ` | ` | 0 | 0 |

2.9. to 3.3. | 0 | ` | ` | ` | 0 |

|

|

|

|

|

|

LEGEND

` Ð In®nity

Step 2 Ð Check the Display LEDs

1.Enter Quick Test mode.

2.If 88 is not displayed, replace display board.

Step 3 Ð Check Set Point Potentiometer Ð Advance the dis- play to quick test step 1.9. to determine if this potentiometer is set and connected properly.

Step 4 Ð Check Display Switch Ð Press switch. If switch does not click, it is faulty and the display will be energized continuously. The switch is an integral part of display board and cannot be replaced separately.

ACCESSORY BOARD CHECKOUT Ð The accessory board can be completely checked using quick test steps 2.0., 2.2., and 2.3. It can also be checked out as follows:

1.Remove the accessory board connector from the proces- sor board and connect an ohmmeter to terminals 3 and 4 on the connector. Numbers are marked on the connector. See Fig. 15.

2.Set the meter to 10,000 ohms. The resistance value ob- tained should be 3,333 ohms. Adjust the potentiometers and the resistance value should not change.

3.Connect the ohmmeter to terminals 3 and 6. As the reset limit potentiometer is turned clockwise, resistance should increase from 0 to approximately 3,400 ohms.

4.Connect the ohmmeter to terminals 3 and 5. As the econo- mizer minimum position potentiometer is turned clock- wise, resistance should increase from 0 to approximately 3,400 ohms.

5.Connect the ohmmeter to terminals 3 and 2. As the

If any of the Steps 1 through 5 result in any other ohm reading, replace the board; it cannot be serviced.

The board can only be checked when it is connected to the processor and the processor is energized so that the DLCM is supplied with 5 vdc power. The terminals referenced are shown in Fig. 16. Potentiometers P1 and P2 refer to the DLCM potentiometers.

IMPORTANT: Be careful to avoid damaging the con- nector or the processor board when taking the voltage readings.

Test under the following conditions:

·No power to IN1 or IN2

Terminal 1 to 2 should read 4.5 vdc ±0.1 v Terminal 2 to 3 should read 5.0 vdc ±0.1 v

·Power to IN2 or to both IN1 and IN2, and P2 set at 24% Terminal 1 to 2 should read 1.5 vdc ± 0.1 v

NOTE: Voltage should vary between 0.5 vdc and 2.5 vdc as the setting of P2 is varied between 0% and 49%.

Terminal 2 to 3 should read 5.0 vdc ± 0.1 v

·Power to IN1 only and P1 set at 50% Terminal 1 to 2 should read 2.5 vdc ± 0.1 v Terminal 2 to 3 should read 5.0 vdc ± 0.1 v

NOTE: Voltage should vary between 0.5 vdc and 2.5 vdc as the setting of P2 is varied between 50% and 100%.

NOTE: If the voltages listed in these 3 tests are not obtained during testing, the DLCM board must be replaced.

Enthalpy Sensor Checkout Ð To test operation of enthalpy sensor, see Table 28.

Table 28 Ð Enthalpy Sensor Checkout

TEST | EXPECTED RESULT |

| AND RESPONSE |

| |

Enthalpy sensor + terminal | Milliammeter reading should be |

should be connected to + | between 3 and 24 mA if sensor |

terminal on motor. Connect the | is operating correctly. If reading |

positive terminal of a DC | is 0 mA, the sensor is either |

milliammeter to the S terminal | wired backwards or is defective. |

of the sensor and the negative |

|

terminal of the meter to SO |

|

terminal of the enthalpy board. |

|

Milliammeter reading should be | |

Enthalpy sensor + terminal | between 3 and 24 mA if sensor |

should be connected to + | is operating correctly. If reading |

terminal on motor. Connect the | is 0 mA, the sensor is either |

positive terminal of a DC | wired backwards or is defective. |

milliammeter to the S terminal |

|

of the sensor and the negative |

|

terminal of the meter to SR |

|

terminal of the enthalpy board. |

|

51