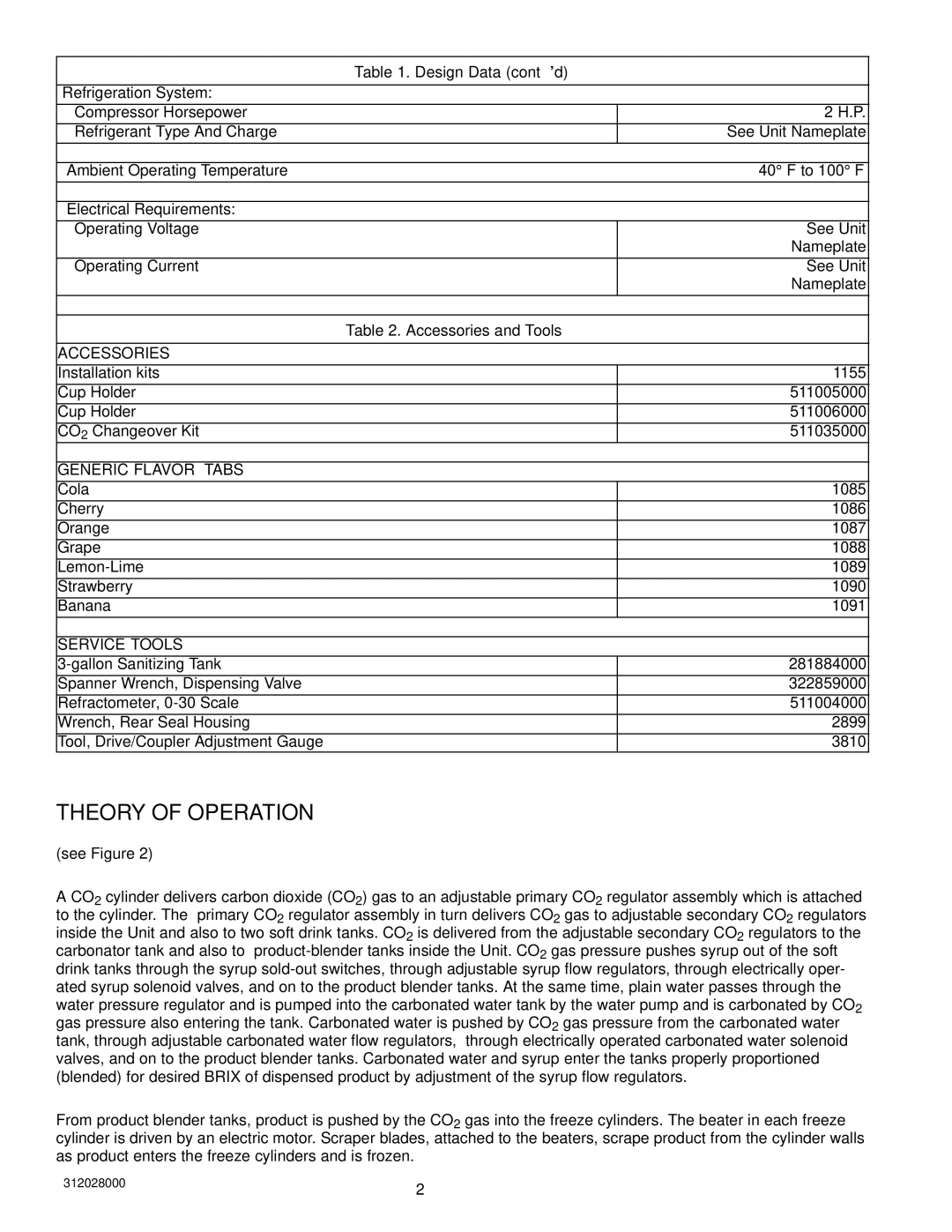

| Table 1. Design Data (cont’d) | |

Refrigeration System: |

|

|

Compressor Horsepower |

| 2 H.P. |

Refrigerant Type And Charge |

| See Unit Nameplate |

|

|

|

Ambient Operating Temperature |

| 40° F to 100° F |

|

|

|

Electrical Requirements: |

|

|

Operating Voltage |

| See Unit |

|

| Nameplate |

|

|

|

Operating Current |

| See Unit |

|

| Nameplate |

|

|

|

| Table 2. Accessories and Tools | |

ACCESSORIES |

|

|

|

|

|

Installation kits |

| 1155 |

Cup Holder |

| 511005000 |

Cup Holder |

| 511006000 |

CO2 Changeover Kit |

| 511035000 |

|

|

|

GENERIC FLAVOR TABS |

|

|

Cola |

| 1085 |

Cherry |

| 1086 |

Orange |

| 1087 |

Grape |

| 1088 |

| 1089 | |

Strawberry |

| 1090 |

Banana |

| 1091 |

|

|

|

SERVICE TOOLS |

|

|

| 281884000 | |

Spanner Wrench, Dispensing Valve |

| 322859000 |

Refractometer, |

| 511004000 |

Wrench, Rear Seal Housing |

| 2899 |

Tool, Drive/Coupler Adjustment Gauge |

| 3810 |

THEORY OF OPERATION

(see Figure 2)

A CO2 cylinder delivers carbon dioxide (CO2) gas to an adjustable primary CO2 regulator assembly which is attached to the cylinder. The primary CO2 regulator assembly in turn delivers CO2 gas to adjustable secondary CO2 regulators inside the Unit and also to two soft drink tanks. CO2 is delivered from the adjustable secondary CO2 regulators to the carbonator tank and also to

From product blender tanks, product is pushed by the CO2 gas into the freeze cylinders. The beater in each freeze cylinder is driven by an electric motor. Scraper blades, attached to the beaters, scrape product from the cylinder walls as product enters the freeze cylinders and is frozen.

312028000 | 2 |

|