SETTING THE BEVEL LOCK LEVER

See Figures 18A

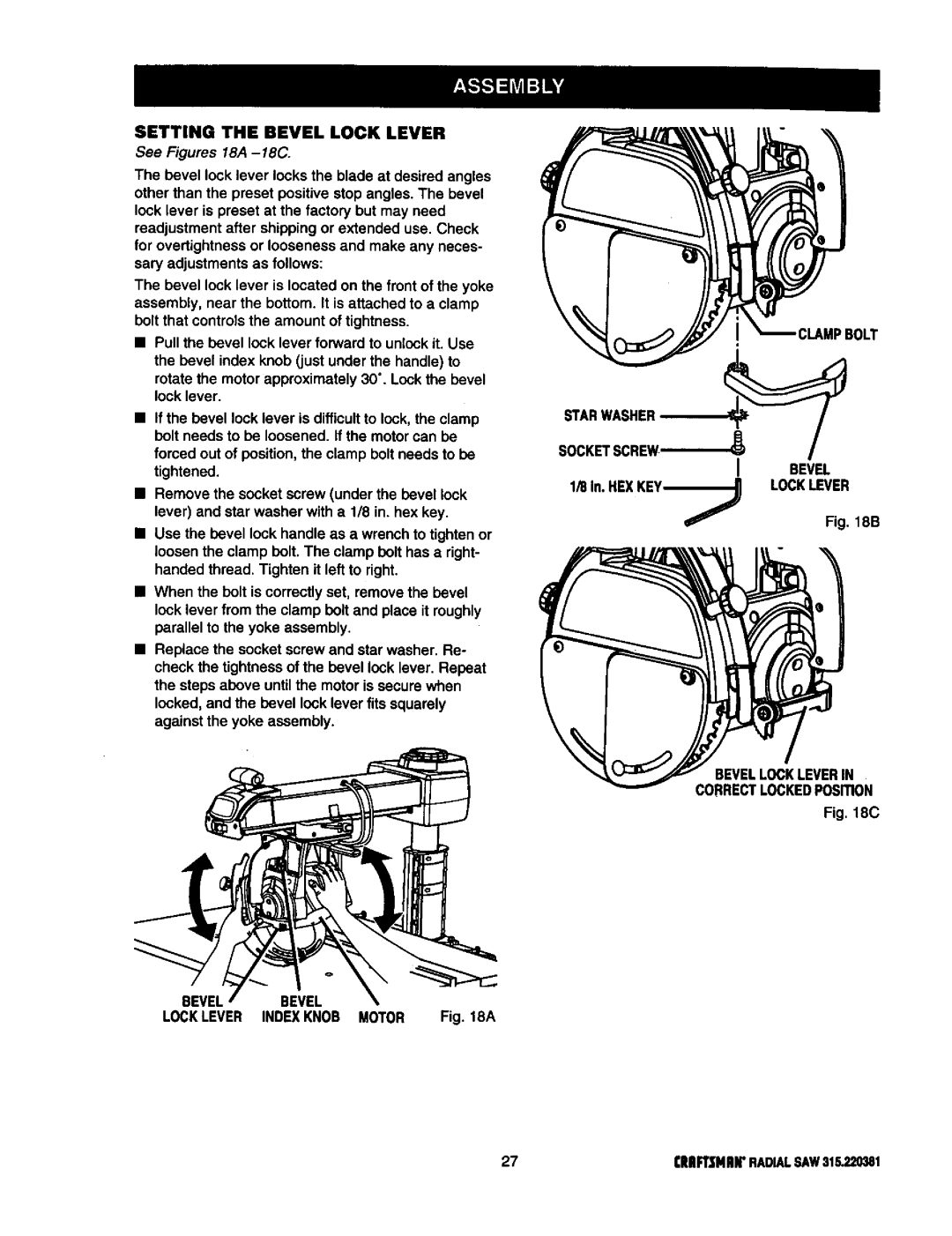

The bevel lock lever locks the blade at desired angles other than the preset positive stop angles. The bevel lock lever is preset at the factory but may need readjustment after shippingor extended use. Check for overUghtnessor looseness and make any neces- sary adjustments as follows:

The bevel lock lever is located on the front of the yoke assembly, near the bottom. It is attached to a clamp bolt that controlsthe amount of tightness.

•Pull the bevel lock lever forward to unlock it. Use the bevel index knob (just under the handle) to

rotate the motor approximately 30 °. Lock the bevel lock lever.

•If the bevel lock lever is difficultto lock, the clamp bolt needs to be loosened. If the motorcan be

forced out of position, the clamp belt needs to be tightened.

•Remove the socket screw (under the bevel lock lever) and star washer with a 1/8 in. hex key.

•Use the bevel lock handle as a wrench to tighten or loosen the clamp belt. The clamp bolt has a right- handed thread. Tighten it left to right.

•When the bolt is correctly set, remove the bevel lock lever from the clamp bolt and place it roughly parallel to the yoke assembly.

•Replace the socket screw and star washer. Re- check the tightness of the bevel lock lever. Repeat the steps above until the motor is secure when locked, and the bevel lock lever fits squarely against the yoke assembly.

STARWASHER

BEVEL

LOCKLEVER

1/8

Fig. 18B

BEVELLOCKLEVERIN

CORRECTLOCKEDPosmoN

Fig. 18C

BEVEL BEVEL

LOCKLEVER INDEXKNOB MOTOR Fig. 18A

27 | [RIIFTSMIIIr RADIALSAW31S.22_1 |