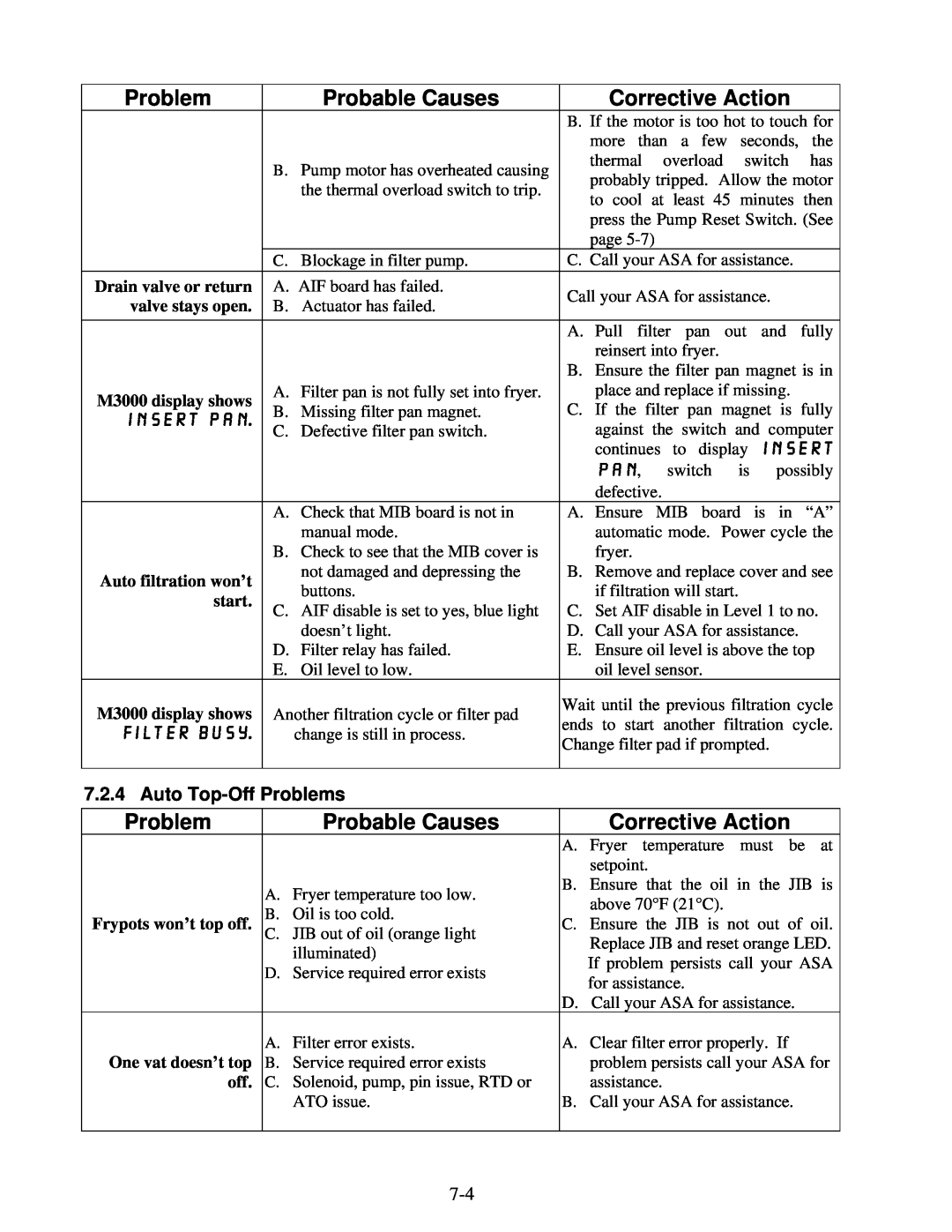

Problem |

| Probable Causes |

| Corrective Action |

| |||||

|

|

| B. If the motor is too hot to touch for | |||||||

|

|

|

| more than a few seconds, the | ||||||

| B. Pump motor has overheated causing |

| thermal | overload | switch | has | ||||

|

| probably tripped. Allow the motor | ||||||||

|

| the thermal overload switch to trip. |

| |||||||

|

|

| to cool at least 45 minutes then | |||||||

|

|

|

| |||||||

|

|

|

| press the Pump Reset Switch. (See | ||||||

|

|

|

| page |

|

|

|

| ||

| C. Blockage in filter pump. | C. Call your ASA for assistance. |

| |||||||

Drain valve or return | A. AIF board has failed. | Call your ASA for assistance. |

|

| ||||||

valve stays open. | B. | Actuator has failed. |

|

| ||||||

|

|

|

|

|

|

| ||||

|

|

| A. Pull filter pan | out | and | fully | ||||

|

|

|

| reinsert into fryer. |

|

|

|

| ||

|

|

| B. Ensure the filter pan magnet is in | |||||||

M3000 display shows | A. Filter pan is not fully set into fryer. |

| place and replace if missing. |

| ||||||

B. | Missing filter pan magnet. | C. | If the | filter pan magnet is fully | ||||||

INSERT pan. | ||||||||||

C. | Defective filter pan switch. |

| against the switch and computer | |||||||

|

| |||||||||

|

|

|

| continues to display | INSERT | |||||

|

|

|

| pan, switch is possibly | ||||||

|

|

|

| defective. |

|

|

|

| ||

| A. Check that MIB board is not in | A. Ensure | MIB board is in “A” | |||||||

|

| manual mode. |

| automatic mode. Power cycle the | ||||||

| B. | Check to see that the MIB cover is |

| fryer. |

|

|

|

|

| |

Auto filtration won’t |

| not damaged and depressing the | B. | Remove and replace cover and see | ||||||

| buttons. |

| if filtration will start. |

|

|

| ||||

start. |

|

|

|

|

| |||||

C. | AIF disable is set to yes, blue light | C. Set AIF disable in Level 1 to no. | ||||||||

| ||||||||||

|

| doesn’t light. | D. Call your ASA for assistance. |

| ||||||

| D. | Filter relay has failed. | E. Ensure oil level is above the top | |||||||

| E. | Oil level to low. |

| oil level sensor. |

|

|

|

| ||

M3000 display shows | Another filtration cycle or filter pad | Wait until the previous filtration cycle | ||||||||

ends to start another filtration | cycle. | |||||||||

filter busy. |

| change is still in process. | ||||||||

| Change filter pad if prompted. |

|

| |||||||

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

| ||

7.2.4 Auto |

|

|

|

|

|

|

| |||

Problem |

| Probable Causes |

| Corrective Action |

| |||||

|

|

| A. Fryer | temperature | must | be | at | |||

|

|

|

| setpoint. |

|

|

|

| ||

| A. Fryer temperature too low. | B. | Ensure | that the oil in | the | JIB is | ||||

|

| above 70°F (21°C). |

|

|

|

| ||||

Frypots won’t top off. | B. | Oil is too cold. |

|

|

|

|

| |||

C. | Ensure | the JIB is | not | out | of | oil. | ||||

| C. JIB out of oil (orange light |

| Replace JIB and reset orange LED. | |||||||

|

| illuminated) |

| |||||||

|

|

| If problem persists call your ASA | |||||||

| D. Service required error exists |

| ||||||||

|

| for assistance. |

|

|

|

| ||||

|

|

|

|

|

|

|

| |||

|

|

| D. Call your ASA for assistance. |

| ||||||

One vat doesn’t top | A. | Filter error exists. | A. | Clear filter error properly. If |

| |||||

B. | Service required error exists |

| problem persists call your ASA for | |||||||

off. | C. | Solenoid, pump, pin issue, RTD or |

| assistance. |

|

|

|

| ||

|

| ATO issue. | B. | Call your ASA for assistance. |

| |||||

|

|

|

|

|

|

|

|

|

| |

Page 72

Image 72