DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.7.8 Replacing the Frypot (cont.)

13.Remove steel line from

(Prior to removal, absorbent cloth or paper towels should be placed under the oil line to catch any oil remaining in the lines.)

Holding backup while unscrewing flare nut on oil-return line.

14.Unscrew both flare fittings completely prior to line removal. Remove

Remove

15.Turning the

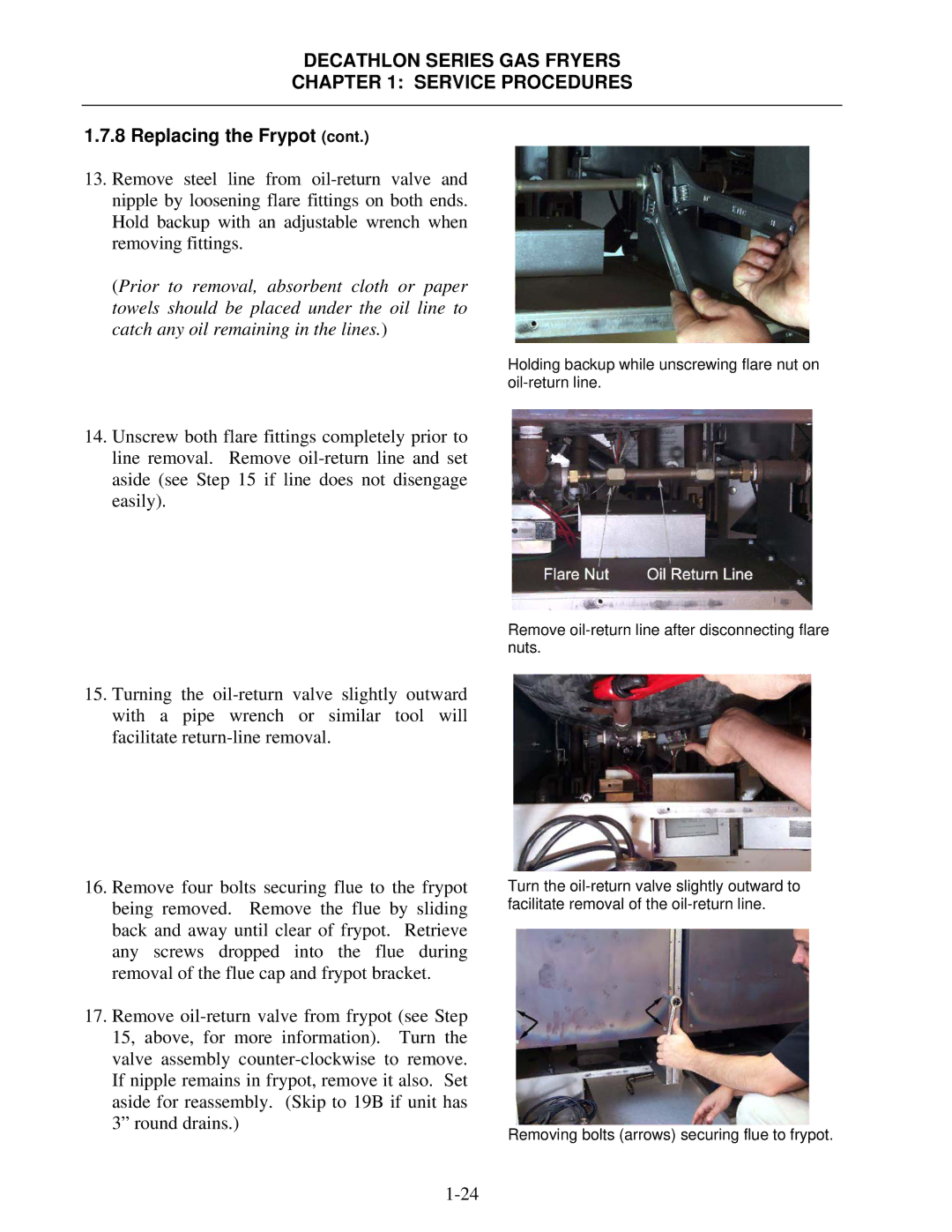

16.Remove four bolts securing flue to the frypot being removed. Remove the flue by sliding back and away until clear of frypot. Retrieve any screws dropped into the flue during removal of the flue cap and frypot bracket.

17.Remove

Turn the

Removing bolts (arrows) securing flue to frypot.