5.Look at what the tension gauge reads and use that as a guide for tensioning that blade in the future.

Note: Do not rely on this setting for long periods of time because the blade will stretch with use.

Additionally, with extended use, the blade tensioning system may need to be reset for correct operation. Refer to the Resetting Blade Tensioner in the Service section on this manual.

When using a 3⁄4" blade, the blade tensioning system may need to be reset for correct operation. Refer to Blade Tensioner on Page 53 for detailed instructions.

Adjusting Blade Support Bearings

The support bearings are positioned behind the blade to prevent it from deflecting backward dur- ing cutting operations. Proper adjustment of the support bearings is an important part of making accurate cuts and keeps the blade teeth from coming in contact with the blade guides while cutting.

There are support bearings on the upper and lower blade guide assemblies. Both adjust in the same manner.

Whenever changing a blade or adjusting tension and tracking, the upper and lower support bearings and blade guides must be

Tool Needed | Qty |

Wrench 10mm | .....................................................1 |

To adjust the support bearings:

1.Make sure the blade is tracking properly and is correctly tensioned.

2.DISCONNECT BANDSAW FROM POWER!

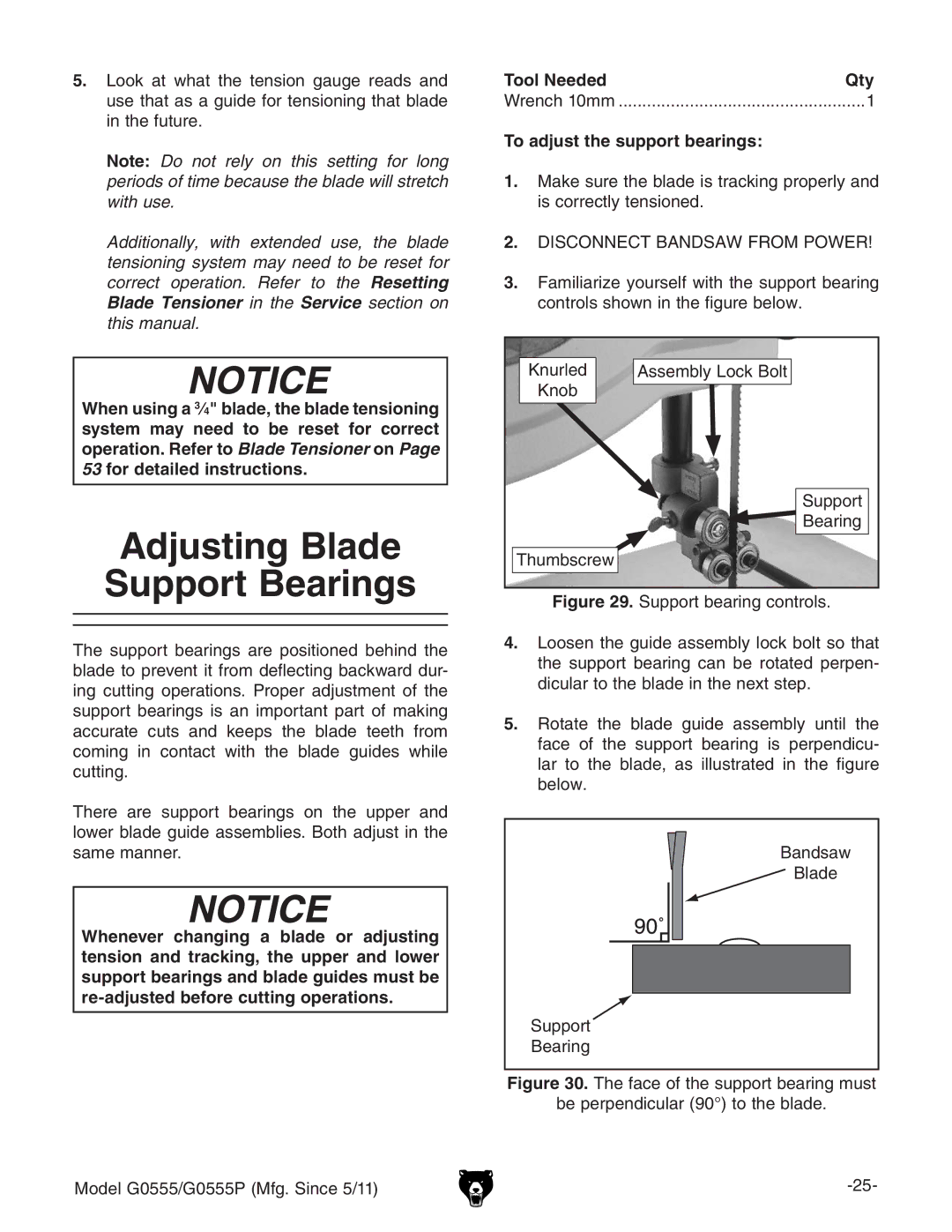

3.Familiarize yourself with the support bearing controls shown in the figure below.

Knurled | Assembly Lock Bolt |

Knob |

|

| Support |

| Bearing |

Thumbscrew |

|

Figure 29. Support bearing controls.

4.Loosen the guide assembly lock bolt so that the support bearing can be rotated perpen- dicular to the blade in the next step.

5.Rotate the blade guide assembly until the face of the support bearing is perpendicu- lar to the blade, as illustrated in the figure below.

Bandsaw

Blade

Blade

Support

Bearing

Figure 30. The face of the support bearing must

be perpendicular (90°) to the blade.

Model G0555/G0555P (Mfg. Since 5/11) |