V-Belt Tension

To ensure optimum power transmission from the motor to the blade, the

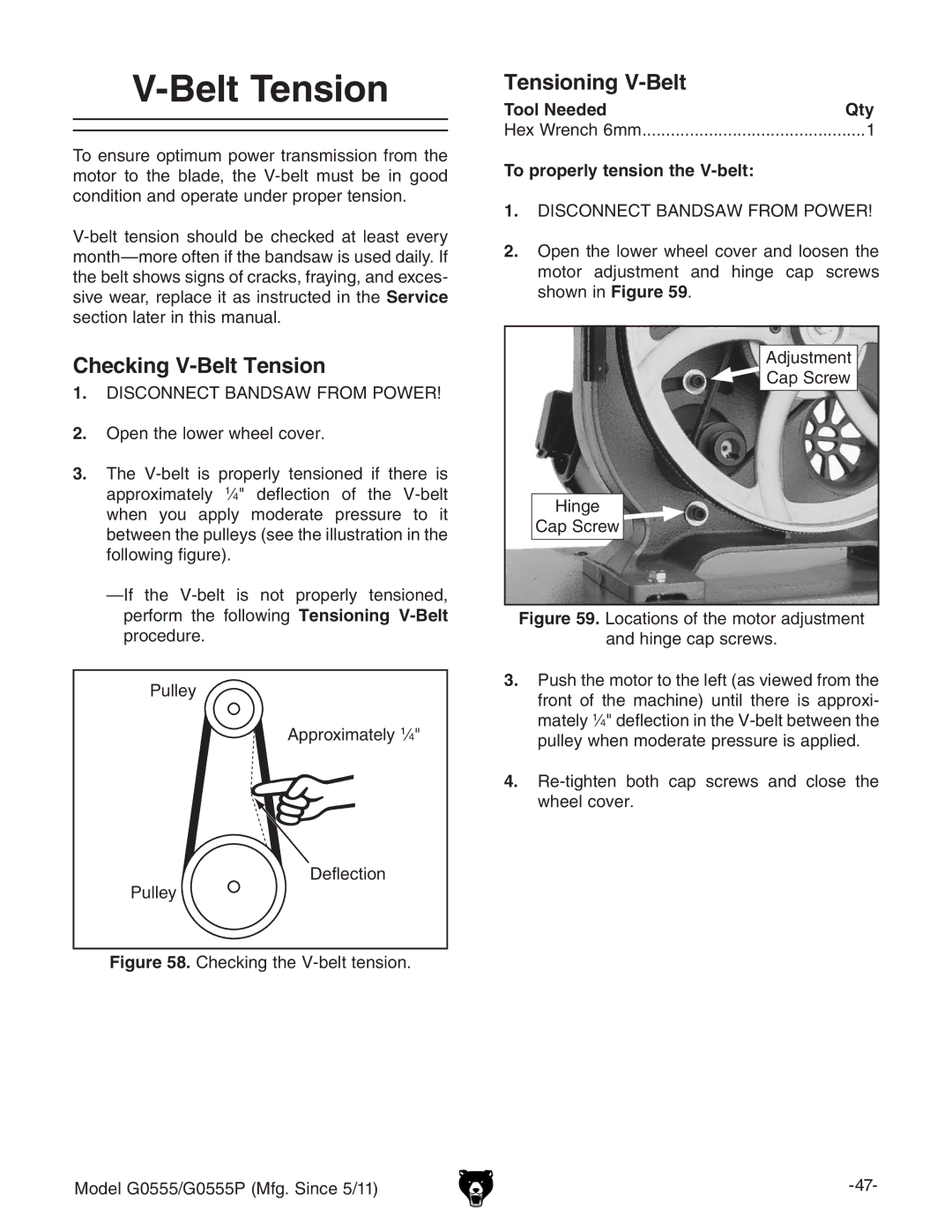

Checking V-Belt Tension

1.DISCONNECT BANDSAW FROM POWER!

2.Open the lower wheel cover.

3.The

Pulley

Approximately 1⁄4"

Deflection

Pulley

Figure 58. Checking the V-belt tension.

Model G0555/G0555P (Mfg. Since 5/11)

Tensioning |

|

Tool Needed | Qty |

Hex Wrench 6mm | 1 |

To properly tension the |

|

1.DISCONNECT BANDSAW FROM POWER!

2.Open the lower wheel cover and loosen the motor adjustment and hinge cap screws shown in Figure 59.

Adjustment

![]() Cap Screw

Cap Screw

Hinge

Cap Screw