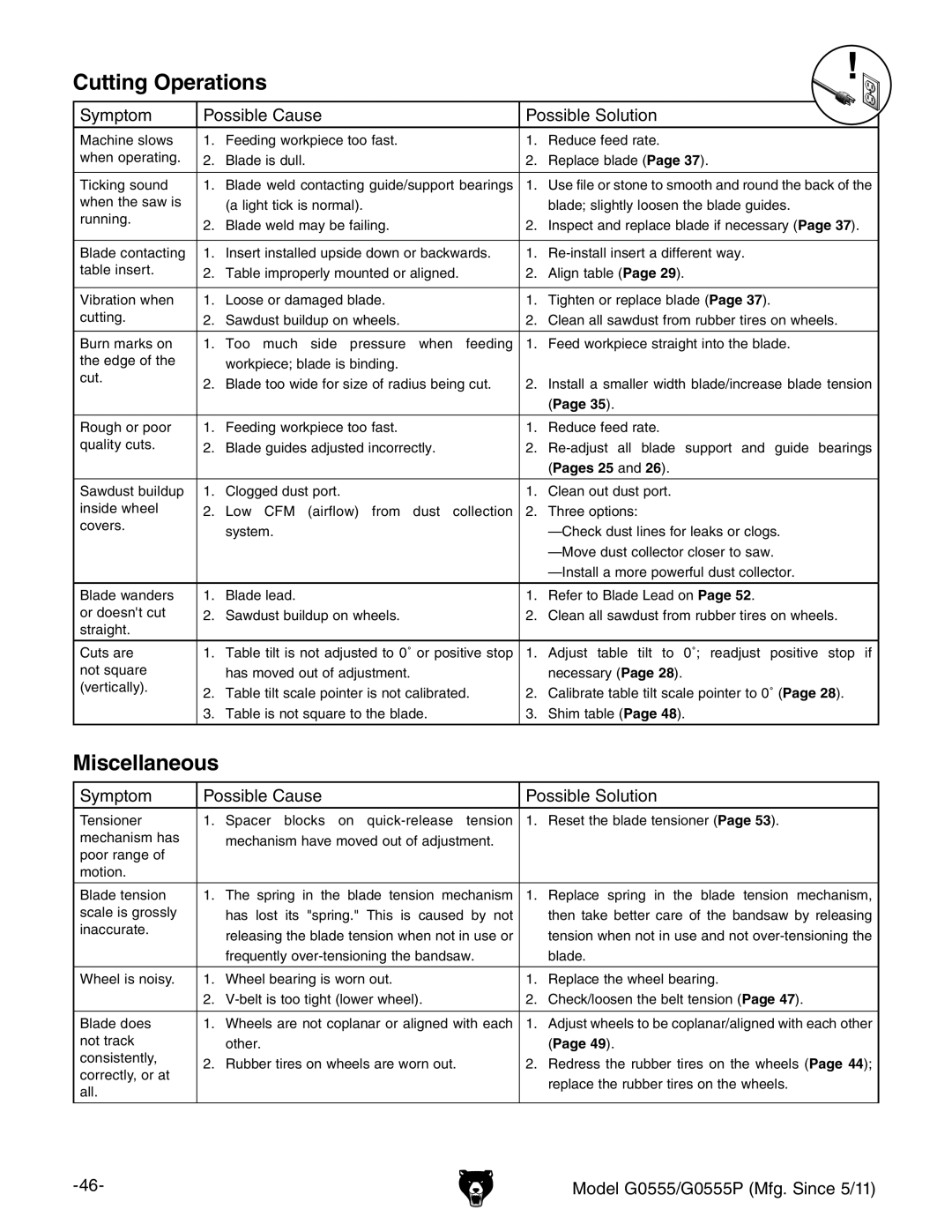

Cutting Operations

Symptom

Possible Cause

Possible Solution

Machine slows | 1. | Feeding workpiece too fast. | 1. | Reduce feed rate. |

when operating. | 2. | Blade is dull. | 2. | Replace blade (Page 37). |

|

|

|

|

|

Ticking sound | 1. | Blade weld contacting guide/support bearings | 1. | Use file or stone to smooth and round the back of the |

when the saw is |

| (a light tick is normal). |

| blade; slightly loosen the blade guides. |

running. | 2. | Blade weld may be failing. | 2. | Inspect and replace blade if necessary (Page 37). |

| ||||

|

|

|

|

|

Blade contacting | 1. | Insert installed upside down or backwards. | 1. | |

table insert. | 2. | Table improperly mounted or aligned. | 2. | Align table (Page 29). |

|

|

|

|

|

Vibration when | 1. | Loose or damaged blade. | 1. | Tighten or replace blade (Page 37). |

cutting. | 2. | Sawdust buildup on wheels. | 2. | Clean all sawdust from rubber tires on wheels. |

|

|

|

|

|

Burn marks on | 1. | Too much side pressure when feeding | 1. | Feed workpiece straight into the blade. |

the edge of the |

| workpiece; blade is binding. |

|

|

cut. | 2. | Blade too wide for size of radius being cut. | 2. | Install a smaller width blade/increase blade tension |

| ||||

|

|

|

| (Page 35). |

|

|

|

|

|

Rough or poor | 1. | Feeding workpiece too fast. | 1. | Reduce feed rate. |

quality cuts. | 2. | Blade guides adjusted incorrectly. | 2. | |

|

|

|

| (Pages 25 and 26). |

|

|

|

|

|

Sawdust buildup | 1. | Clogged dust port. | 1. | Clean out dust port. |

inside wheel | 2. | Low CFM (airflow) from dust collection | 2. | Three options: |

covers. |

| system. |

| |

|

|

| ||

|

|

|

| |

|

|

|

| |

|

|

|

|

|

Blade wanders | 1. | Blade lead. | 1. | Refer to Blade Lead on Page 52. |

or doesn't cut | 2. | Sawdust buildup on wheels. | 2. | Clean all sawdust from rubber tires on wheels. |

straight. |

|

|

|

|

Cuts are | 1. | Table tilt is not adjusted to 0˚ or positive stop | 1. | Adjust table tilt to 0˚; readjust positive stop if |

not square |

| has moved out of adjustment. |

| necessary (Page 28). |

(vertically). | 2. | Table tilt scale pointer is not calibrated. | 2. | Calibrate table tilt scale pointer to 0˚ (Page 28). |

| ||||

| 3. | Table is not square to the blade. | 3. | Shim table (Page 48). |

|

|

|

|

|

Miscellaneous

Symptom | Possible Cause | Possible Solution | |||

|

|

|

|

| |

Tensioner | 1. | Spacer blocks on | 1. | Reset the blade tensioner (Page 53). | |

mechanism has |

| mechanism have moved out of adjustment. |

|

| |

poor range of |

|

|

|

| |

motion. |

|

|

|

| |

|

|

|

|

| |

Blade tension | 1. | The spring in the blade tension mechanism | 1. | Replace spring in the blade tension mechanism, | |

scale is grossly |

| has lost its "spring." This is caused by not |

| then take better care of the bandsaw by releasing | |

inaccurate. |

| releasing the blade tension when not in use or |

| tension when not in use and not | |

|

|

| |||

|

| frequently |

| blade. | |

|

|

|

|

| |

Wheel is noisy. | 1. | Wheel bearing is worn out. | 1. | Replace the wheel bearing. | |

| 2. | 2. | Check/loosen the belt tension (Page 47). | ||

|

|

|

|

| |

Blade does | 1. | Wheels are not coplanar or aligned with each | 1. | Adjust wheels to be coplanar/aligned with each other | |

not track |

| other. |

| (Page 49). | |

consistently, | 2. | Rubber tires on wheels are worn out. | 2. | Redress the rubber tires on the wheels (Page 44); | |

correctly, or at | |||||

|

|

| replace the rubber tires on the wheels. | ||

all. |

|

|

| ||

|

|

|

| ||

|

|

|

|

| |

Model G0555/G0555P (Mfg. Since 5/11) |