Replacing V-Belt

To ensure optimum power transmission from the motor to the blade, the

If the belt shows signs of cracks, fraying, and excessive wear, replace it.

Tools Needed | Qty |

Hex Wrench 6mm | 1 |

Wrench or Socket 13mm | 1 |

Replacement | 1 |

To replace the |

|

1.DISCONNECT BANDSAW FROM POWER!

2.Put on heavy leather gloves and remove the blade from the machine.

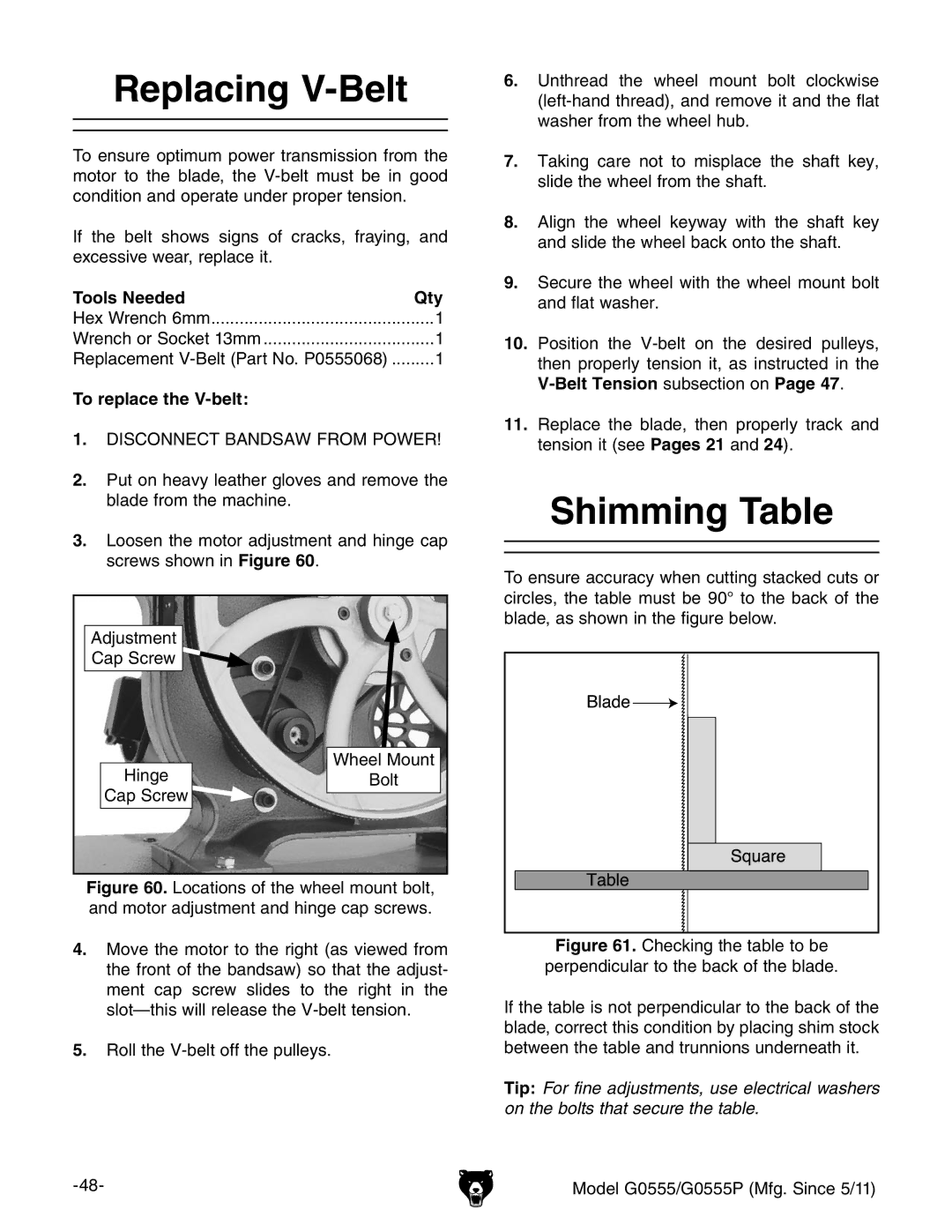

3.Loosen the motor adjustment and hinge cap screws shown in Figure 60.

6.Unthread the wheel mount bolt clockwise

7.Taking care not to misplace the shaft key, slide the wheel from the shaft.

8.Align the wheel keyway with the shaft key and slide the wheel back onto the shaft.

9.Secure the wheel with the wheel mount bolt and flat washer.

10.Position the

V-Belt Tension subsection on Page 47.

11.Replace the blade, then properly track and tension it (see Pages 21 and 24).

Shimming Table

To ensure accuracy when cutting stacked cuts or circles, the table must be 90° to the back of the blade, as shown in the figure below.

Adjustment

Cap Screw ![]()

Hinge

Cap Screw![]()

Wheel Mount

Bolt

Figure 60. Locations of the wheel mount bolt, and motor adjustment and hinge cap screws.

4.Move the motor to the right (as viewed from the front of the bandsaw) so that the adjust- ment cap screw slides to the right in the slot—this will release the V-belt tension.

5.Roll the V-belt off the pulleys.

Figure 61. Checking the table to be perpendicular to the back of the blade.

If the table is not perpendicular to the back of the blade, correct this condition by placing shim stock between the table and trunnions underneath it.

Tip: For fine adjustments, use electrical washers on the bolts that secure the table.

Model G0555/G0555P (Mfg. Since 5/11)