E.Motor Start Button: Turns the motor ON when there is power to the machine.

F.Motor Stop Button: Turns the motor OFF.

G.Normal/Inch Switch: In Normal position, the beam moves to the end of the arc in the direction selected, then returns to the opposite end of the arc. In Inch position, the beam stops where it is when the foot actuator is released or it has reached the end of the

H.Punch/Notch Switch: Selects which direc- tion the beam moves when the foot actuator is depressed.

I.Foot Actuator: Initiates the beam move- ment.

Operation Tips

•To produce quality cuts and avoid damage to your machine, stay within the operational capacities of your machine.

•Adjust the table guides, strippers, or hold- downs to keep the workpiece from unexpect- edly moving up during the operation without restricting movement of the workpiece when required for the next cut.

•Use liberal lubrication on the dies and workpiece to reduce friction and wear on the tooling.

•The quality of the cut edges are an immediate indicator of the die condition. keep the dies clean of debris and mill scale. Sharp tool- ing cuts cleaner and with less wear on the machine.

•To avoid damage to the machine or tooling, cut completely through the workpiece unless you are using tooling designed for partial cut- ting.

•Dies are sharp! Always wear heavy leather gloves when handling the dies to protect your hands.

G0646/G0647 50/65 Ton Ironworker

punching station tips

Punching

Use the punching station to perform general die work, bar bending, corner notching, and tube notching (additional tooling may be required for some processes). The punching table and guides accept a wide variety of workpiece shapes, and the front portion of the table is removable for flange punching. The limit stops are adjustable to set the most efficient stroke length for your opera- tion (refer to Page 33).

Use the following formula to calculate the maxi- mum punch diameter for the workpiece (all values are in millimeters):

���������������� � ����������������

������������������� ��������

The machine constants are: |

|

Model G0646 | 330 |

Model G0647 | 420 |

Using the Punching Station

1.Set the controls to Notch and Inch, then raise the punching die up so that you can insert the workpiece.

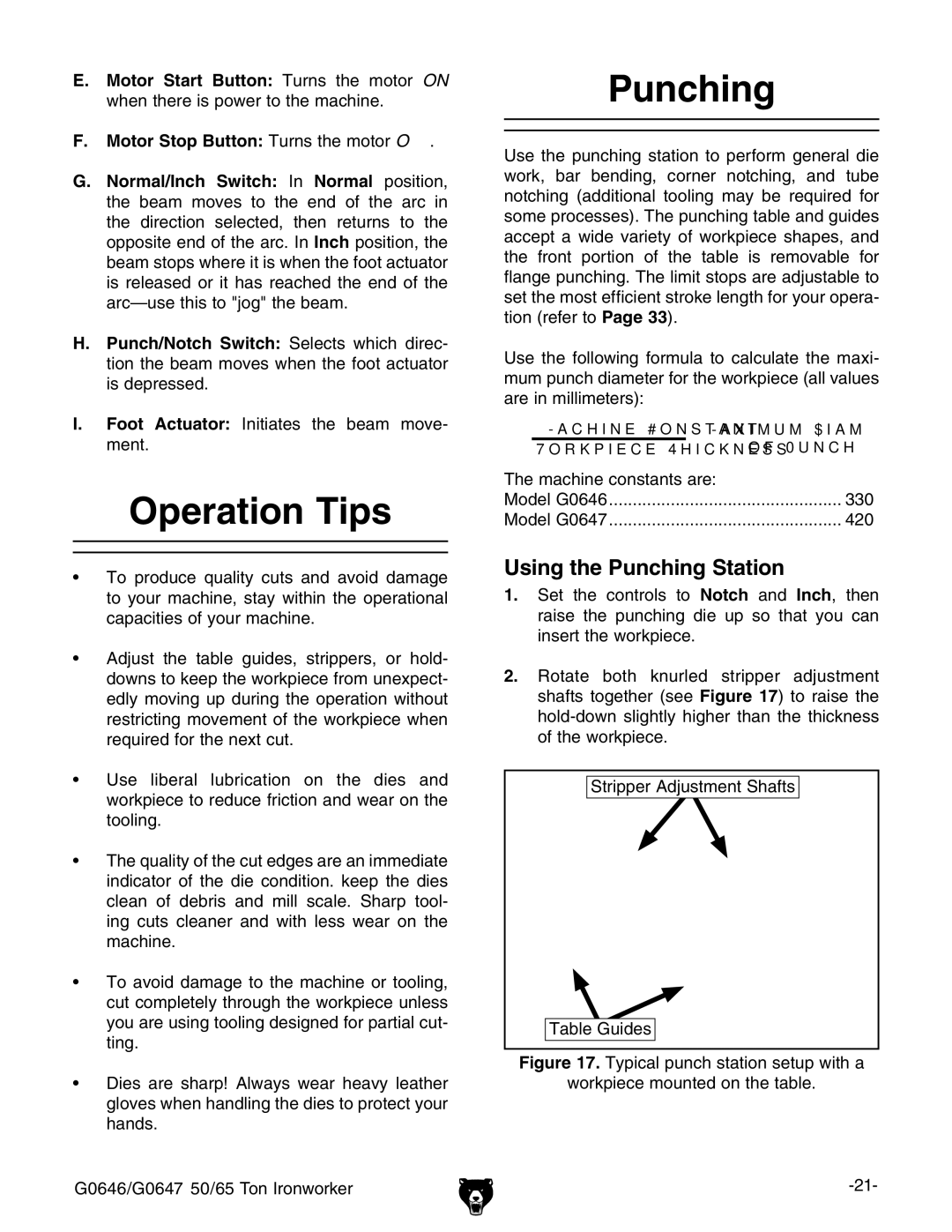

2.Rotate both knurled stripper adjustment shafts together (see Figure 17) to raise the

Stripper Adjustment Shafts

Table Guides