6.Set the controls for Notch and Normal, then use the pedal actuator to perform the shear- ing operation.

Note: Make sure the cut piece falls through the rear exit panel and away from the dies so that it does not interfere with the next opera- tion.

The workpiece MUST extend through the support frame and beyond the dies to avoid sudden unexpected movement of the workpiece when cutting (refer to the illustra- tion in Figure 31 on Page 28). Fully support and flag long workpieces to reduce the risk of hazards.

Extension Bar

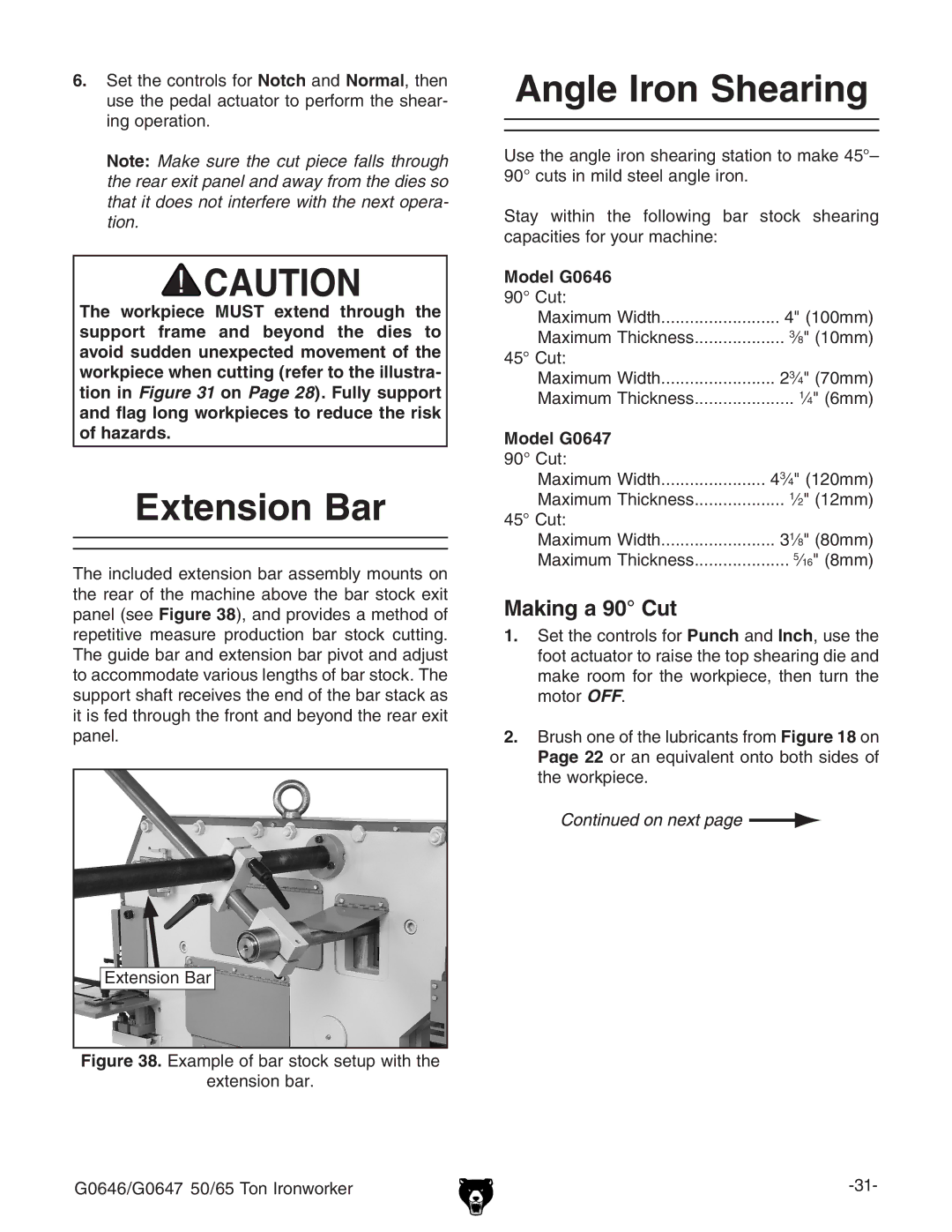

The included extension bar assembly mounts on the rear of the machine above the bar stock exit panel (see Figure 38), and provides a method of repetitive measure production bar stock cutting. The guide bar and extension bar pivot and adjust to accommodate various lengths of bar stock. The support shaft receives the end of the bar stack as it is fed through the front and beyond the rear exit panel.

Extension Bar

Figure 38. Example of bar stock setup with the

extension bar.

G0646/G0647 50/65 Ton Ironworker

Angle Iron Shearing

Use the angle iron shearing station to make 45°– 90° cuts in mild steel angle iron.

Stay within the following bar stock shearing capacities for your machine:

Model G0646 |

|

90° Cut: |

|

Maximum Width | 4" (100mm) |

Maximum Thickness | 3⁄8" (10mm) |

45° Cut: |

|

Maximum Width | 23⁄4" (70mm) |

Maximum Thickness | 1⁄4" (6mm) |

Model G0647 |

|

90° Cut: |

|

Maximum Width | 43⁄4" (120mm) |

Maximum Thickness | 1⁄2" (12mm) |

45° Cut: |

|

Maximum Width | 31⁄8" (80mm) |

Maximum Thickness | 5⁄16" (8mm) |

Making a 90° Cut

1.Set the controls for Punch and Inch, use the foot actuator to raise the top shearing die and make room for the workpiece, then turn the motor OFF.

2.Brush one of the lubricants from Figure 18 on Page 22 or an equivalent onto both sides of the workpiece.