INTRODUCTION

Foreword |

| Functional Overview |

|

|

|

|

|

|

We are proud to offer the Model G0646/G0647 50/65 Ton Ironworker. This machine is part of a growing Grizzly family of fine machinery. When used according to the guidelines set forth in this manual, you can expect years of

The specifications, drawings, and photographs illustrated in this manual represent the Model G0646/G0647 when the manual was prepared. However, owing to Grizzly’s policy of continuous improvement, changes may be made at any time with no obligation on the part of Grizzly.

For your convenience, we always keep current Grizzly manuals available on our website at www.grizzly.com. Any updates to your machine will be reflected in these manuals as soon as they are complete.

Contact Info

We stand behind our machines. If you have any service questions, parts requests or general ques- tions about the machine, please call or write us at the location listed below.

Grizzly Industrial, Inc.

1203 Lycoming Mall Circle

Muncy, PA 17756

Phone: (570)

Fax: (800)

If you have any comments regarding this manual, please write to us at the address below:

Grizzly Industrial, Inc.

C/O Technical Documentation Manager

P.O. Box 2069

Bellingham, WA

Email: manuals@grizzly.com

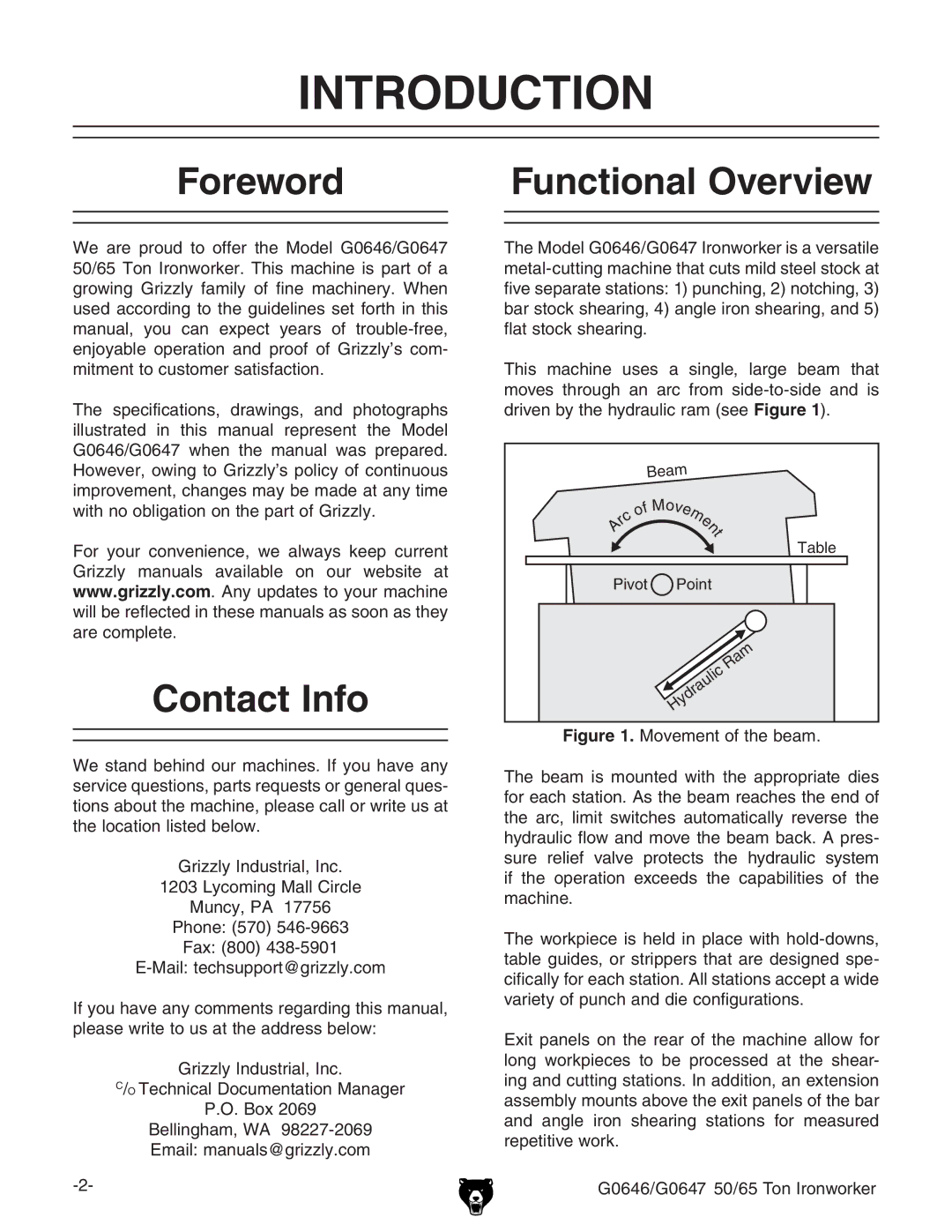

The Model G0646/G0647 Ironworker is a versatile

This machine uses a single, large beam that moves through an arc from

����

|

|

| �� | � |

|

|

|

| �� | � |

| ||

| � |

|

| � | ||

� |

|

|

|

| ||

� | � |

|

|

|

| � |

� |

|

|

|

|

| � |

|

|

|

|

|

| � |

�����

����� ![]() �����

�����

�������������