5.Install the front die into the bolster and fully secure it with the two cap screws.

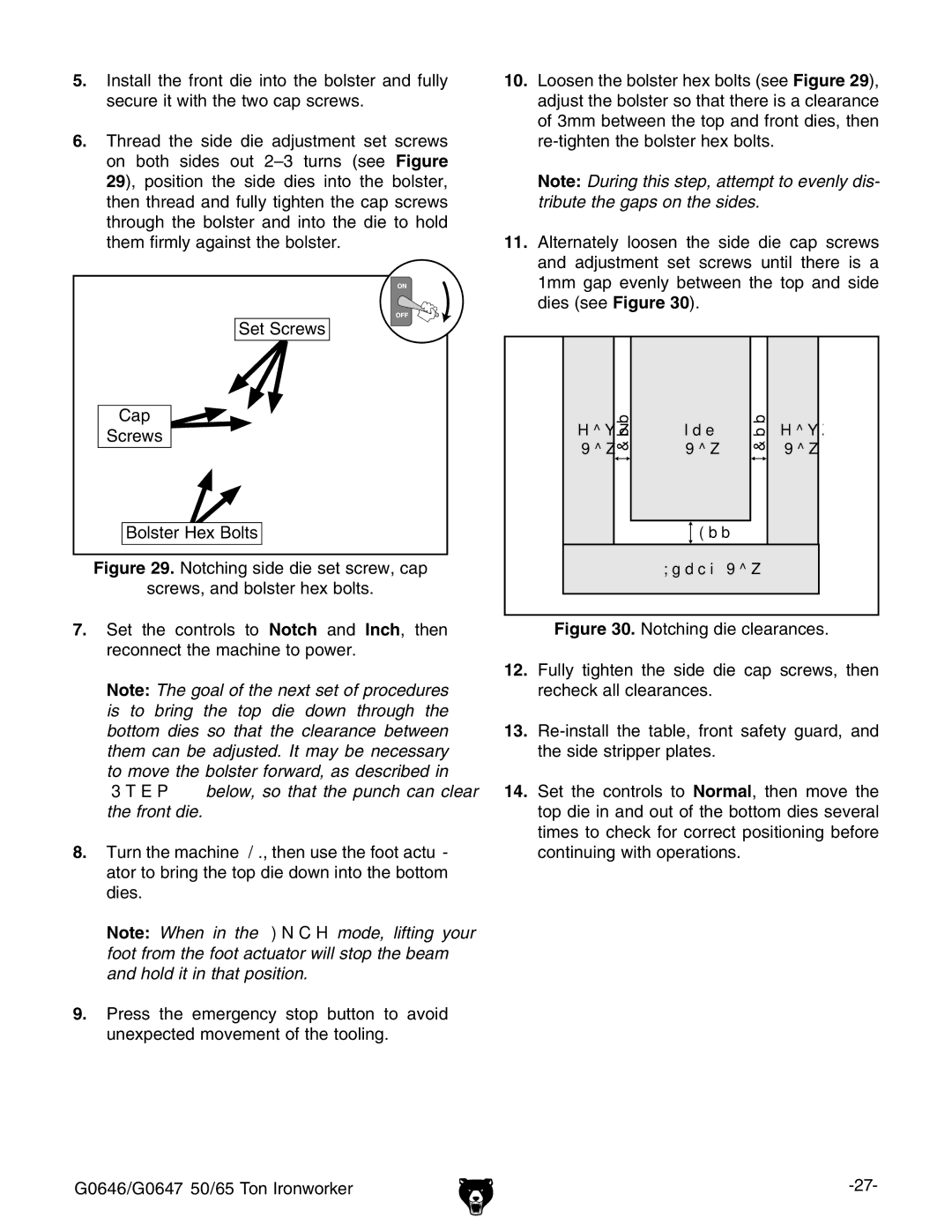

6.Thread the side die adjustment set screws on both sides out

Set Screws

Cap

Screws

Bolster Hex Bolts

Figure 29. Notching side die set screw, cap

screws, and bolster hex bolts.

7.Set the controls to Notch and Inch, then reconnect the machine to power.

Note: The goal of the next set of procedures is to bring the top die down through the bottom dies so that the clearance between them can be adjusted. It may be necessary to move the bolster forward, as described in Step 10 below, so that the punch can clear the front die.

8.Turn the machine ON, then use the foot actu- ator to bring the top die down into the bottom dies.

Note: When in the Inch mode, lifting your foot from the foot actuator will stop the beam and hold it in that position.

9.Press the emergency stop button to avoid unexpected movement of the tooling.

10.Loosen the bolster hex bolts (see Figure 29), adjust the bolster so that there is a clearance of 3mm between the top and front dies, then re-tighten the bolster hex bolts.

Note: During this step, attempt to evenly dis- tribute the gaps on the sides.

11.Alternately loosen the side die cap screws and adjustment set screws until there is a 1mm gap evenly between the top and side dies (see Figure 30).

��� | ��� | ��� | ��� | ��� |

���� |

| ��� |

| ���� |

![]() ���

���

���������

Figure 30. Notching die clearances.

12. Fully tighten the side die cap screws, then recheck all clearances.

13. Re-install the table, front safety guard, and the side stripper plates.

14. Set the controls to Normal, then move the top die in and out of the bottom dies several times to check for correct positioning before continuing with operations.

G0646/G0647 50/65 Ton Ironworker |