The edges of ironwork- er tooling are very sharp and can quickly cut fin- gers and hands. Always wear heavy leather gloves when handling tooling to avoid injury.

4.Remove the table guides, unthread the three flat head cap screws securing the notch- ing table (see Figure 26), then remove the table.

Figure 26. Flat head cap screws that secure the

notching table.

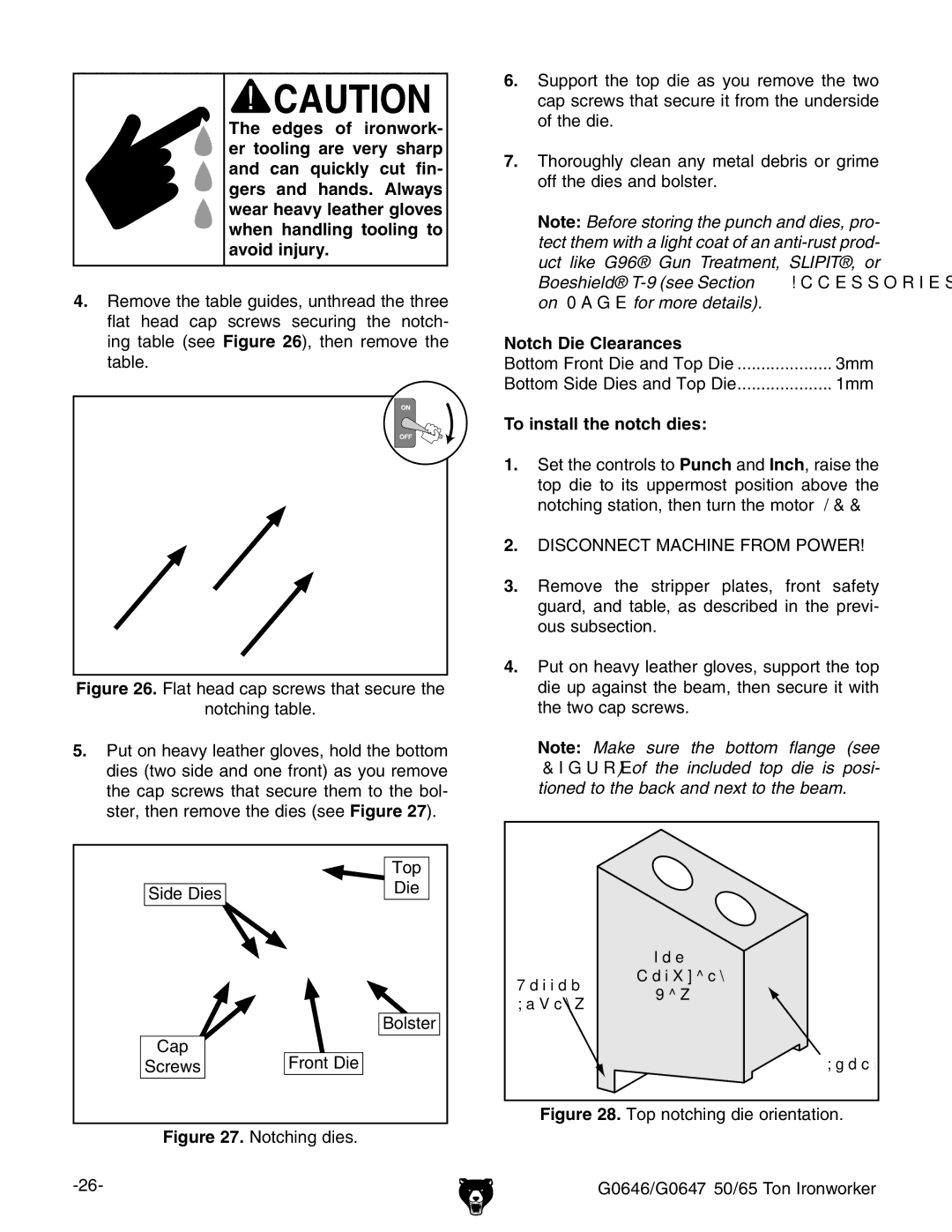

5.Put on heavy leather gloves, hold the bottom dies (two side and one front) as you remove the cap screws that secure them to the bol- ster, then remove the dies (see Figure 27).

| Top |

Side Dies | Die |

| |

| Bolster |

Cap | Front Die |

Screws |

Figure 27. Notching dies.

6.Support the top die as you remove the two cap screws that secure it from the underside of the die.

7.Thoroughly clean any metal debris or grime off the dies and bolster.

Note: Before storing the punch and dies, pro- tect them with a light coat of an

Notch Die Clearances |

|

Bottom Front Die and Top Die | 3mm |

Bottom Side Dies and Top Die | 1mm |

To install the notch dies: |

|

1.Set the controls to Punch and Inch, raise the top die to its uppermost position above the notching station, then turn the motor OFF.

2.DISCONNECT MACHINE FROM POWER!

3.Remove the stripper plates, front safety guard, and table, as described in the previ- ous subsection.

4.Put on heavy leather gloves, support the top die up against the beam, then secure it with the two cap screws.

Note: Make sure the bottom flange (see Figure 28) of the included top die is posi- tioned to the back and next to the beam.

| ��� | |

������ | �������� | |

��� | ||

������ | ||

|

�����