Site Considerations

Floor Load

Refer to the Machine Data Sheets (beginning on Page 4) for the weight and footprint specifications of your machine. Some floors may require addi- tional reinforcement to support both the machine and operator.

Placement Location

Consider existing and anticipated needs, size of material to be processed through each machine, and space for auxiliary stands, work tables or other machinery when establishing a location for your new machine. See Figures

���

���

Figure 10. Model G0646 minimum working

clearances.

������

������

Figure 11. Model G0647 minimum working

clearances.

Moving & Placing

Base Unit

The Model G0646/G0647 is

aheavy machine. Serious personal injury may occur if safe moving methods are not used. To be safe, get assistance and use power equipment rated for at least 3500 lbs. to move the shipping crate and remove the machine from the crate.

To move the machine:

1.Remove the crating and plastic wrap, then unbolt the machine from the shipping pallet.

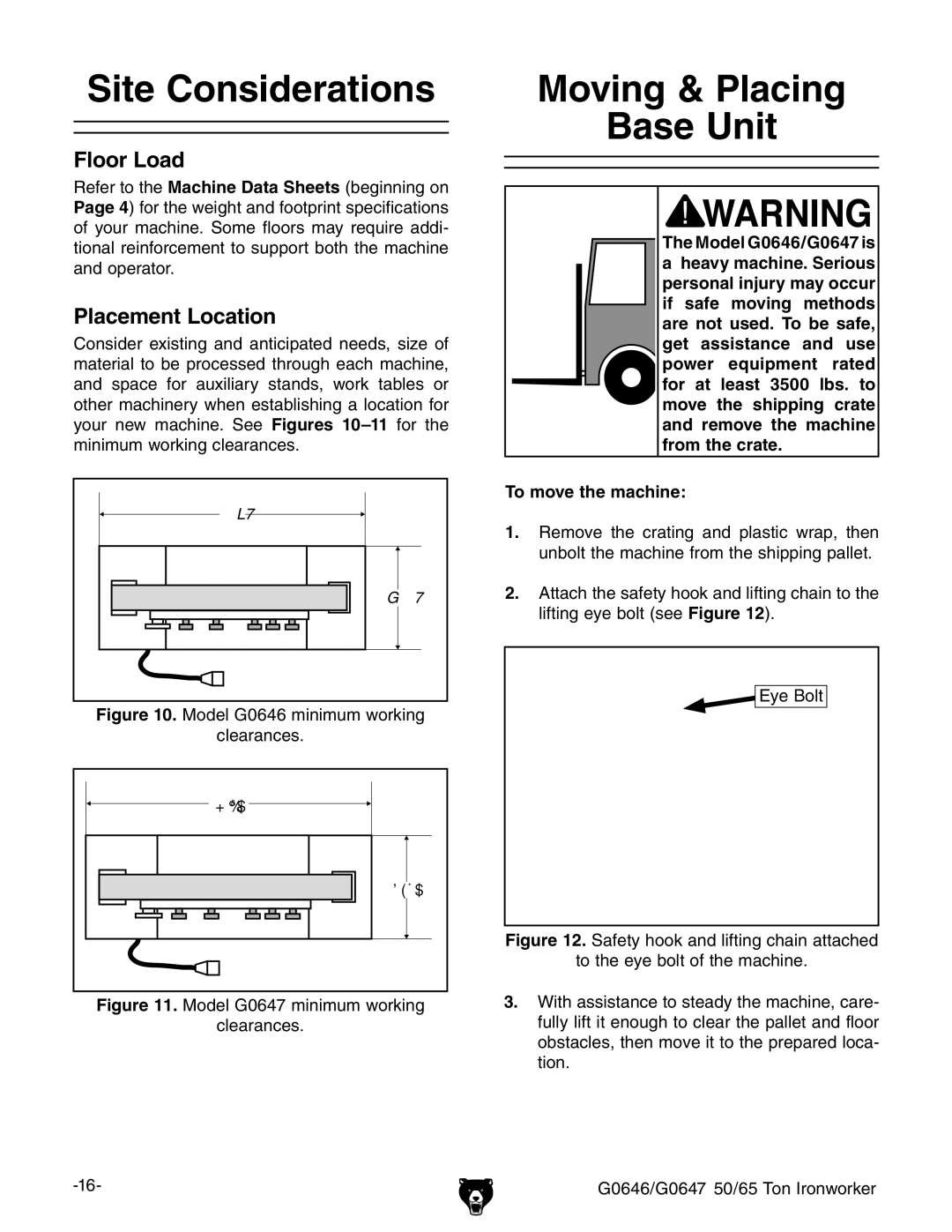

2.Attach the safety hook and lifting chain to the lifting eye bolt (see Figure 12).

Eye Bolt