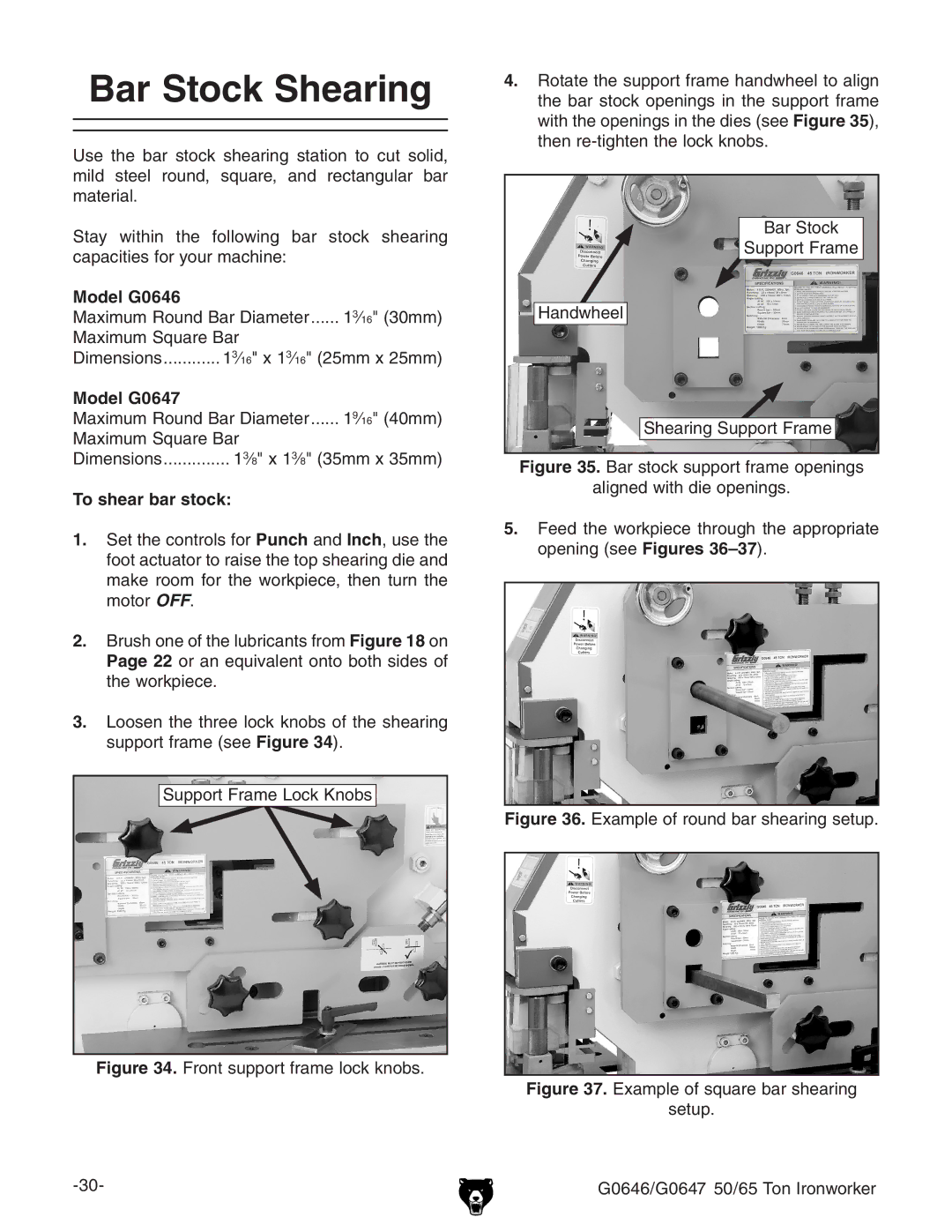

| Bar Stock Shearing | 4. Rotate the support frame handwheel to align | |

| the bar stock openings in the support frame | ||

|

| with the openings in the dies (see Figure 35), | |

Use the bar stock shearing station to cut solid, | then | ||

| |||

mild steel round, square, and rectangular bar |

| ||

material. |

| ||

Stay within the following bar stock shearing | Bar Stock | ||

Support Frame | |||

capacities for your machine: | |||

| |||

Model G0646 | Handwheel | ||

Maximum Round Bar Diameter...... 13⁄16" (30mm) | |||

Maximum Square Bar |

| ||

Dimensions............ 13⁄16" x 13⁄16" (25mm x 25mm) |

| ||

Model G0647 |

| ||

Maximum Round Bar Diameter...... 19⁄16" (40mm) | Shearing Support Frame | ||

Maximum Square Bar | |||

| |||

Dimensions.............. 13⁄8" x 13⁄8" (35mm x 35mm) | Figure 35. Bar stock support frame openings | ||

|

| ||

To shear bar stock: | aligned with die openings. | ||

| |||

1. | Set the controls for Punch and Inch, use the | 5. Feed the workpiece through the appropriate | |

opening (see Figures | |||

| foot actuator to raise the top shearing die and | ||

|

| ||

| make room for the workpiece, then turn the |

| |

| motor OFF. |

| |

2.Brush one of the lubricants from Figure 18 on Page 22 or an equivalent onto both sides of the workpiece.

3.Loosen the three lock knobs of the shearing support frame (see Figure 34).

Support Frame Lock Knobs

Figure 36. Example of round bar shearing setup.

Figure 34. Front support frame lock knobs.

Figure 37. Example of square bar shearing

setup.

G0646/G0647 50/65 Ton Ironworker |