To shear flat stock:

1.Set the controls for Punch and Inch, use the foot actuator to raise the top shearing die and make room for the workpiece, then turn the motor OFF.

2.Brush one of the lubricants from Figure 18 on Page 22 or an equivalent onto both sides of the workpiece.

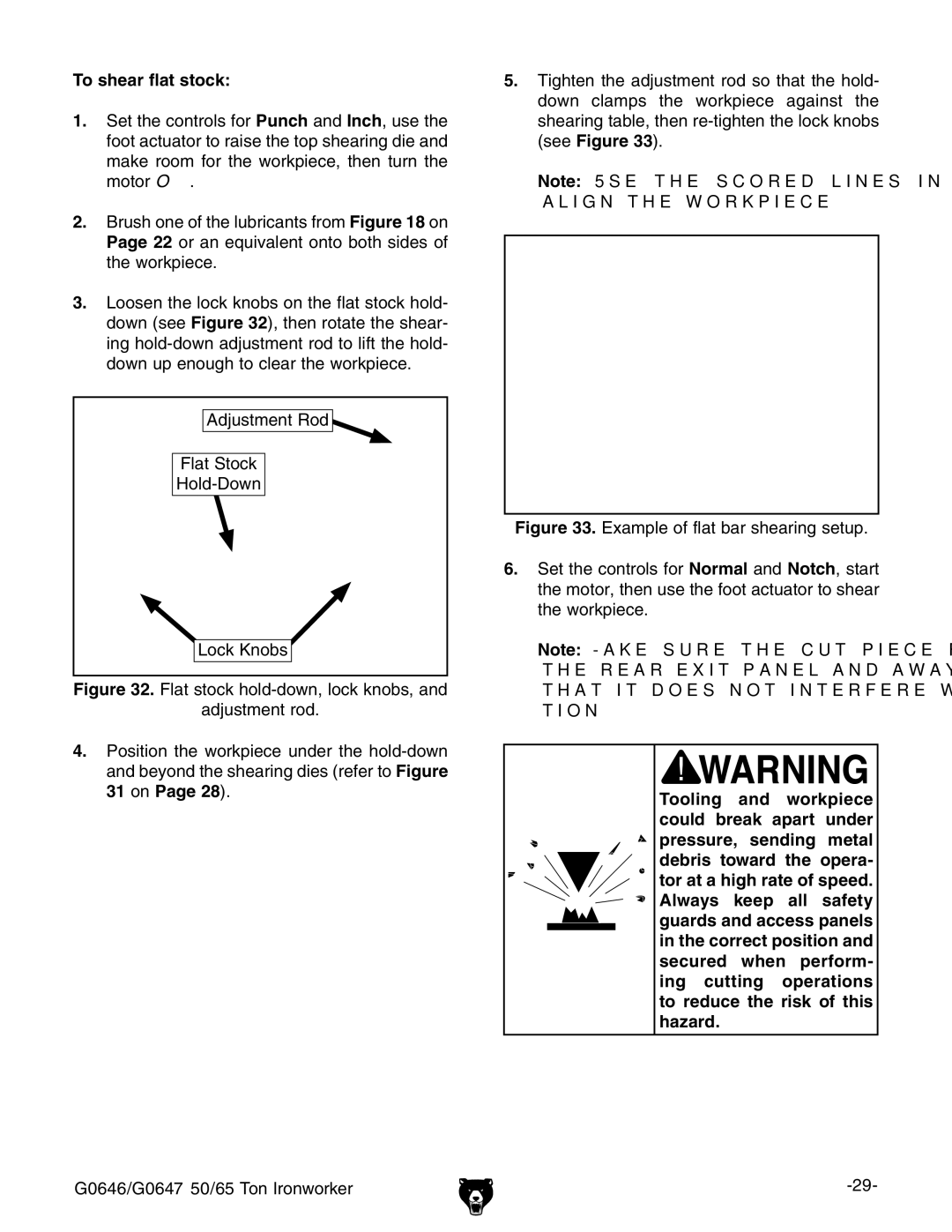

3.Loosen the lock knobs on the flat stock hold- down (see Figure 32), then rotate the shear- ing

Adjustment Rod

Flat Stock

Lock Knobs

Figure 32. Flat stock hold-down, lock knobs, and

adjustment rod.

4.Position the workpiece under the hold-down and beyond the shearing dies (refer to Figure 31 on Page 28).

5.Tighten the adjustment rod so that the hold- down clamps the workpiece against the shearing table, then re-tighten the lock knobs (see Figure 33).

Note: Use the scored lines in the table to align the workpiece.

Figure 33. Example of flat bar shearing setup.

6.Set the controls for Normal and Notch, start the motor, then use the foot actuator to shear the workpiece.

Note: Make sure the cut piece falls through the rear exit panel and away from the dies so that it does not interfere with the next opera- tion.

Tooling and workpiece could break apart under pressure, sending metal debris toward the opera- tor at a high rate of speed. Always keep all safety guards and access panels in the correct position and secured when perform- ing cutting operations to reduce the risk of this hazard.

G0646/G0647 50/65 Ton Ironworker |