11 Gas Information

A. Gas Pressure Requirements

WARNING! Risk of Explosion! An

Pressure requirements for

Two taps are provided on the right hand side of the gas control for a test gauge connection to measure the inlet and outlet pressures.

The fireplace and its individual

If the fireplace must be isolated from the gas supply pip- ing system by closing an individual

![]() WARNING

WARNING

Fire Risk

Explosion Risk

High pressure will damage valve.

•Disconnect gas supply piping BEFORE pressure testing gas line at test pressures above 6 kPa.

•Close the manual shutoff valve BEFORE pressure testing gas line at test pressures equal to or less than 6 kPa.

B.Gas Connection

Note: Have the gas supply line installed in accordance with local building codes by a qualified installer approved and/or licensed as required by the locality.

Note: Before the first firing of the appliance, the gas supply line should be purged of any trapped air.

Note: Consult local building regulations to properly size the gas supply line leading to the (Rp 1/2 in.)

Incoming gas line should be piped into the valve compart- ment and connected to the ISO

Leak test all gas line points and the gas control valve prior to and after starting the gas appliance.

IMPORTANT NOTICE: (Items 1, 2 and 3 applies to ALL Heat & Glo gas appliances)

1.1/2 in. GAS LINE: Run through cavity 70 mm above finished hearth level, NOT RIGID, NOT CLIPPED, with minimum 500 mm into cavity and 120 mm back from plaster face.

2.PVC (COMPOSITE) GASLINE must terminate minimum 500 mm short of gas heater. Copper pipe MUST be the final connection to the gas heater.

3.ISOLATING SWITCH: Location within 1 metre of fireplace, subject to mantelpiece etc. Check to ensure it remains clear of any mantelpiece instal- lation.

Leak test all gas line points and the gas control valve prior to and after starting the gas appliance.

![]() WARNING

WARNING

CHECK FOR GAS LEAKS

Explosion Risk

Fire Risk

Asphyxiation Risk

•Check all fittings and connections.

•Do not use open flame.

•After the gas line installation is complete, all connections must be tightened and checked

for leaks with a

Fittings and connections may have loosened during shipping and handling.

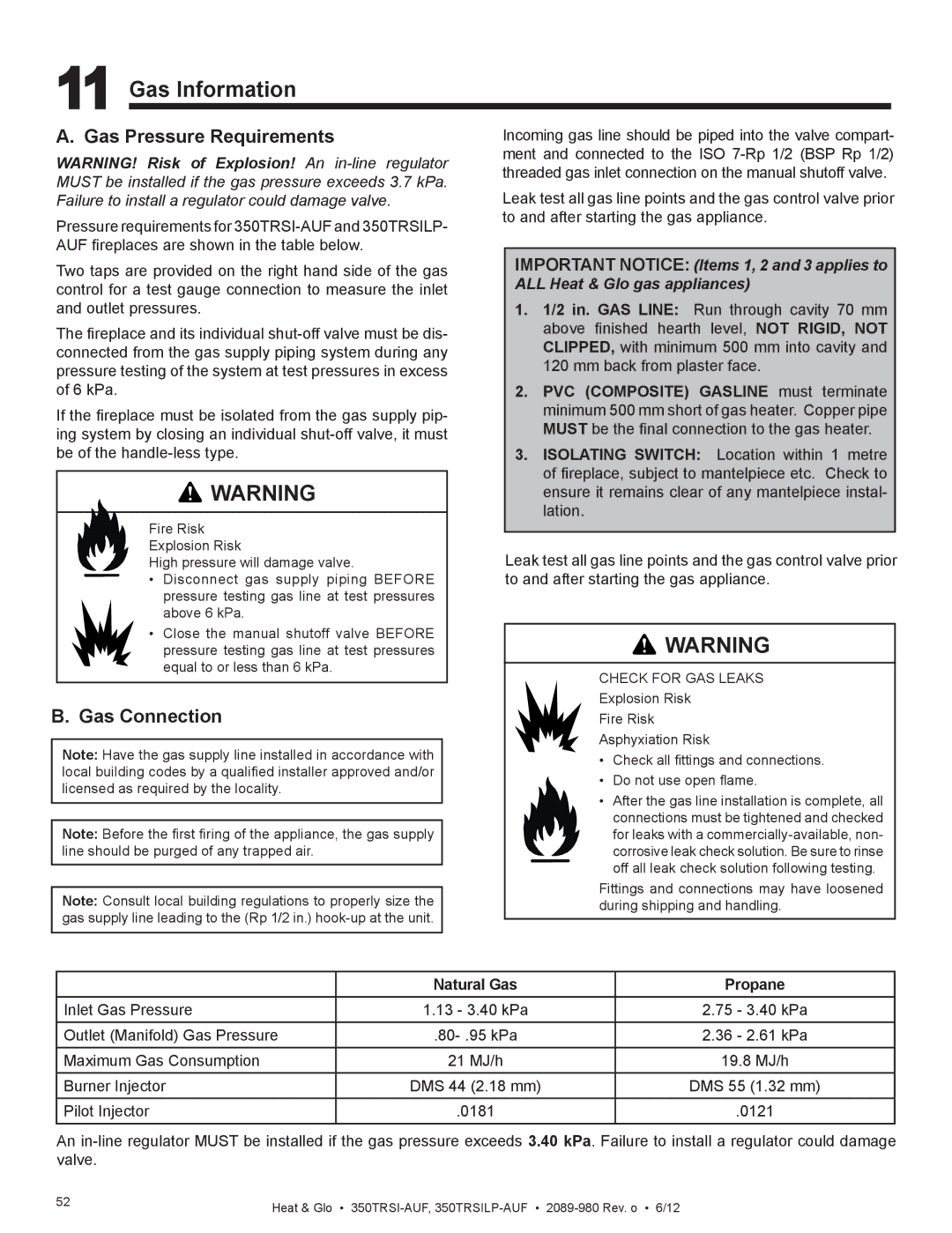

| Natural Gas | Propane |

Inlet Gas Pressure | 1.13 - 3.40 kPa | 2.75 - 3.40 kPa |

Outlet (Manifold) Gas Pressure | 2.36 - 2.61 kPa | |

Maximum Gas Consumption | 21 MJ/h | 19.8 MJ/h |

Burner Injector | DMS 44 (2.18 mm) | DMS 55 (1.32 mm) |

Pilot Injector | .0181 | .0121 |

An

52 | Heat & Glo • |

|