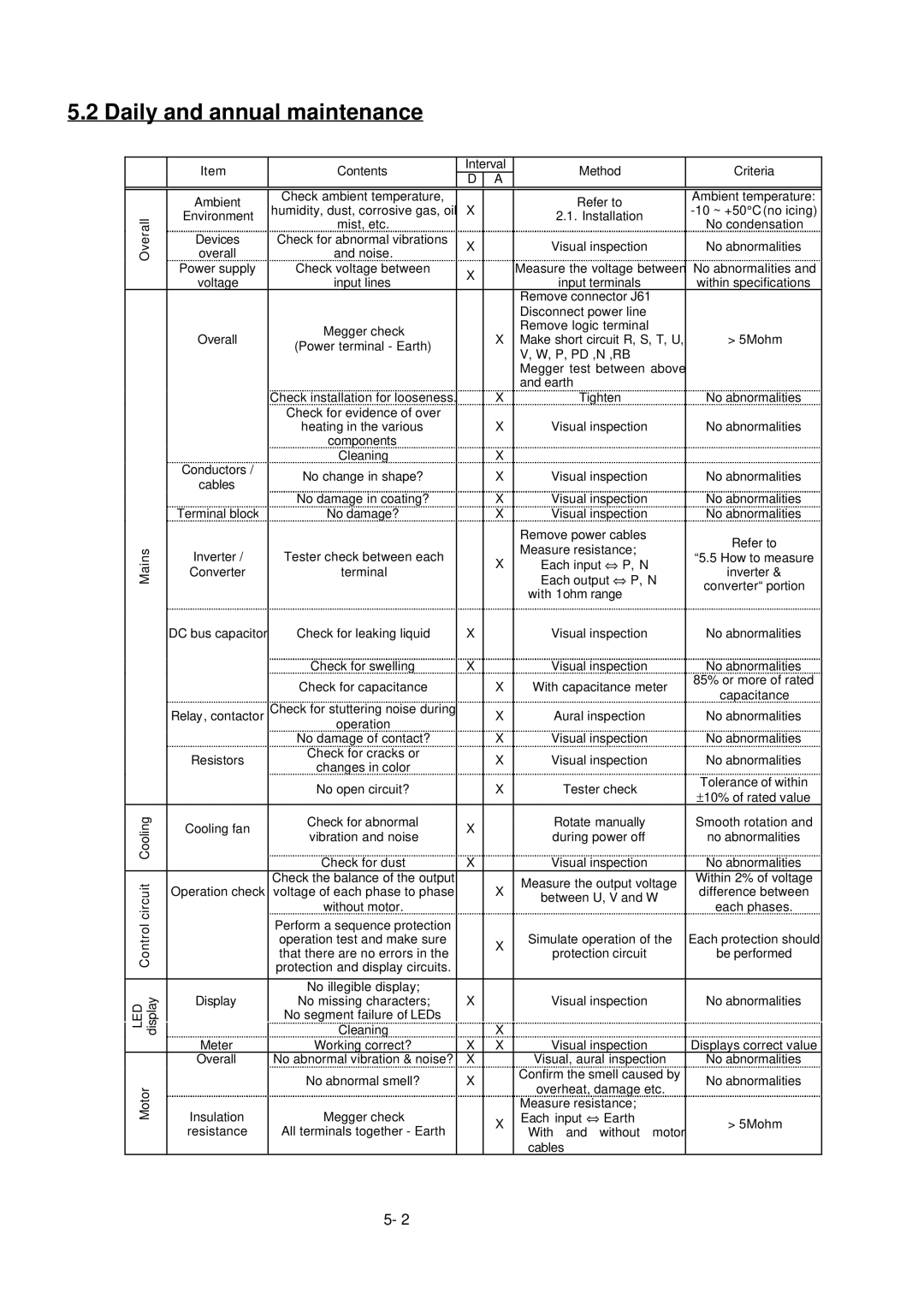

5.2 Daily and annual maintenance

| Item | Contents | Interval | Method | Criteria | |

|

|

| D | A |

|

|

|

|

|

|

|

|

|

| Ambient | Check ambient temperature, |

|

| Refer to | Ambient temperature: |

| humidity, dust, corrosive gas, oil | X |

| |||

Overall | Environment |

| 2.1. Installation | |||

and noise. | X |

| No abnormalities | |||

overall |

| Visual inspection | ||||

|

| mist, etc. |

|

|

| No condensation |

| Devices | Check for abnormal vibrations |

|

|

|

|

| Power supply | Check voltage between | X |

| Measure the voltage between | No abnormalities and |

| voltage | input lines |

| input terminals | within specifications | |

|

|

| ||||

|

|

|

|

| Remove connector J61 |

|

|

|

|

|

| Disconnect power line |

|

|

| Megger check |

|

| Remove logic terminal |

|

| Overall |

| X | Make short circuit R, S, T, U, | > 5Mohm | |

| (Power terminal - Earth) |

| ||||

|

|

|

| V, W, P, PD ,N ,RB |

| |

|

|

|

|

|

| |

|

|

|

|

| Megger test between above |

|

|

|

|

|

| and earth |

|

|

| Check installation for looseness. |

| X | Tighten | No abnormalities |

|

| Check for evidence of over |

|

|

|

|

|

| heating in the various |

| X | Visual inspection | No abnormalities |

|

| components |

|

|

|

|

| Conductors / | Cleaning |

| X |

|

|

| No change in shape? |

| X | Visual inspection | No abnormalities | |

| cables |

| ||||

| No damage in coating? |

| X | Visual inspection | No abnormalities | |

|

|

| ||||

| Terminal block | No damage? |

| X | Visual inspection | No abnormalities |

|

|

|

|

| Remove power cables | Refer to |

Mains | Inverter / | Tester check between each |

|

| Measure resistance; | |

| X | “5.5 How to measure | ||||

| Each output ⇔ P, N | |||||

| Converter | terminal |

| Each input ⇔ P, N | inverter & | |

|

|

|

|

| with 1ohm range | converter“ portion |

|

|

|

|

|

| |

| DC bus capacitor | Check for leaking liquid | X |

| Visual inspection | No abnormalities |

|

| Check for swelling | X |

| Visual inspection | No abnormalities |

|

| Check for capacitance |

| X | With capacitance meter | 85% or more of rated |

|

|

| capacitance | |||

|

| Check for stuttering noise during |

|

|

| |

| Relay, contactor |

| X | Aural inspection | No abnormalities | |

|

| operation |

|

|

|

|

|

| No damage of contact? |

| X | Visual inspection | No abnormalities |

| Resistors | Check for cracks or |

| X | Visual inspection | No abnormalities |

| changes in color |

| ||||

|

|

|

|

| Tolerance of within | |

|

| No open circuit? |

| X | Tester check | |

|

|

| ±10% of rated value | |||

|

|

|

|

|

| |

Cooling | Cooling fan | Check for abnormal | X |

| Rotate manually | Smooth rotation and |

vibration and noise |

| during power off | no abnormalities | |||

|

| |||||

|

|

|

| |||

|

| Check for dust | X |

| Visual inspection | No abnormalities |

circuit |

| Check the balance of the output |

|

| Measure the output voltage | Within 2% of voltage |

Operation check | voltage of each phase to phase |

| X | difference between | ||

| between U, V and W | |||||

|

| |||||

|

| without motor. |

|

| each phases. | |

|

|

|

|

| ||

Control |

| Perform a sequence protection |

|

|

|

|

| operation test and make sure |

| X | Simulate operation of the | Each protection should | |

|

| that there are no errors in the |

| protection circuit | be performed | |

|

|

|

| |||

|

| protection and display circuits. |

|

|

|

|

|

|

|

|

|

|

|

|

| No illegible display; |

|

|

|

|

LED display | Display | No missing characters; | X | X | Visual inspection | No abnormalities |

| Cleaning |

|

|

| ||

|

| No segment failure of LEDs |

|

|

|

|

| Meter | Working correct? | X | X | Visual inspection | Displays correct value |

| Overall | No abnormal vibration & noise? | X |

| Visual, aural inspection | No abnormalities |

|

| No abnormal smell? | X |

| Confirm the smell caused by | No abnormalities |

Motor |

|

| overheat, damage etc. | |||

|

|

|

|

| ||

Insulation | Megger check |

|

| Measure resistance; |

| |

|

|

|

| |||

|

| X | Each input ⇔ Earth | > 5Mohm | ||

| resistance | All terminals together - Earth |

| With and without motor | ||

|

|

|

| |||

|

|

|

|

| cables |

|

5- 2