S e r J e t 0 0 a

Page

User Guide

Warranty

Copyright Hewlett- Packard Company

Trademark Credits

Contents

Printing media

Copying tasks

Troubleshooting the Copier/Scanner

Appendix a Printer specifications

Index

Getting to know the printer

Print with excellent quality

Printer features and benefits

Save money

Create professional documents

Printer components

Ready light

Printer control panel

Printer paper guides

Printer paper input trays

Rear paper input tray

Front single-sheet paper input tray

Printer paper output paths

Paper output bin

Straight-through paper output path

Printer door

Choosing paper and other media

Maximum supported paper size 216 by 356 mm 8.5 by 14

Minimum supported paper size 76 by 127 mm 3 by 5

Specific types

Loading paper into the printer

Voltage conversions

Turning the power off

Printer properties driver

Accessing printer properties driver and help

Windows 9x & NT

Windows

Printer online help

Printer properties online help

Online help

Printing a self-test

Getting to know the printer

Getting to know the Copier/Scanner

Powerful copier software Copier Control Panel

Scanner features and benefits

Scan

Copy

Getting to know the software

Document Assistant Windows 9x & NT

Accessing the Document Assistant

Click Programs Click HP LaserJet Click Document Assistant

Close Document Assistant

Accessing the LaserJet Document Desktop Windows 9x & NT

Accessing the LaserJet Document Desktop Windows

LaserJet Document Desktop Windows 3.1x, 9x, NT

Copier Control Panel

Quick Copy settings

LaserJet Toolbox

Accessing the LaserJet Toolbox Windows 9x & NT

Scanner control panel

Copier/Scanner components

Scanner door

Scanner paper input tray, guides, and output path

Supported paper sizes and types media

Precautions for copying and scanning

Loading Copier/Scanner originals

Accessing the online help

Document Assistant Click Tools, and then click Help

LaserJet Document Desktop Click Help from the main menu

Getting to know the Copier/Scanner

Printing media

Printing transparencies

Printing envelopes

Printing labels

Printing letterhead

Printing cards

Printing tasks

Printing with manual feed

Printing on both sides of the paper manual duplexing

Manual duplex using the paper output bin standard

Manual duplex special heavy-media, card stock

Printing watermarks

Accessing the watermark feature

Accessing the multiple pages per sheet feature

On next

Printing booklets

Page

Canceling a print job

Changing print quality settings

Print using EconoMode save toner

Finishing tab under Print Quality, click EconoMode

Printing tasks

Scanning tasks

Scanning to fax

Using the Fax feature

Scanning to e-mail

Using the E-Mail feature

Editing scanned text OCR

Using the OCR feature

Software application Accessing the online help

Storing scanned text or images

Using the Store feature

Acquiring an image

Accessing the contrast feature

Contrast sensitive originals

Scanning

Accessing image enhancement features

Enhancing the scanned image

Image Enhancement

Accessing the annotation features

Canceling scan or copy jobs

Adding annotations to scanned images

Annotations

Scanning tasks

Copying tasks

Making Quick Copies

Copy overview

Accessing the Quick Copy settings

Using the Copier Control Panel

Canceling copy jobs

Accessing the Copier Control Panel

Managing the toner cartridge

HP toner cartridges

Redistributing toner

Changing the toner cartridge

Troubleshooting the printer

Finding the solution

Pages did not print

Pages printed however

Light status legend

Printer light patterns

Paper out

Error messages on screen Error Message Solution

Error messages on screen

Subdirectory C\Windows\Temp

Paper handling problems Problem Solution

Paper handling problems

Printed page is different than what appeared on screen

Printed page problems Problem Solution

Printed page problems Problem Solution

Image defect examples

Improving print quality

Improving print quality

Light print or fade

Correcting print defects

Toner specks

Dropouts

Toner smear

Gray background

Loose toner

Vertical repetitive defects

Skew

Misformed characters

Curl or wave

Wrinkles or creases

Cleaning the printer

Cleaning the toner cartridge area

Cleaning the printer paper path

Stack when new paper is added. This helps prevent multiple

Clearing printer paper jams

Typical paper jam locations

Removing a jammed

Page

Paper jam removing torn pieces of paper

Changing the pickup roller

Page

Cleaning the pickup roller

Resetting the printer

Troubleshooting the printer

Troubleshooting Copier/Scanner

Copying problems

Scanning problems

Scanner did nothing

Is the wrong printer selected?

Did you send a print or copy job before attempting to scan?

Do you have other devices running on your computer?

No preview appeared on screen

Are you currently copying or printing?

Is the original loaded correctly?

Scanned image is of poor quality

Is the image quality better when printed?

Is the image skewed crooked?

Is the scanner dirty?

Part of the image did not scan or is missing text

Text cannot be edited

Does the original have text that is tightly spaced?

Is the original of poor quality?

Is your printer set for bi-directional communication?

Scan takes too long

Unable to activate Twain source

Error messages appear on the screen

No copy came out or the scanner did nothing

Is paper loaded in the printer paper input tray?

Did you send a print job before attempting to copy?

Copies are blank, missing images, or faded

Preventative steps

Improving scan/copy quality

Image defect examples

Vertical white stripes

Correcting scan/copy defects

Blank pages

Too light or dark

Black dots or streaks

Unclear text

Image prints at reduced size

Calibrating the scanner

Accessing the Calibration utility

Cleaning the scanner

Clearing scanner jams

Clearing jams

Clearing hard-to-reach jams

Removing the scanner

113

Service and support

Availability

Obtaining hardware service

Guidelines for repacking the printer

Guidelines for repacking the scanner

Service information form

Service information form

What needs to be done?

HP Support

European Customer Support Center

Italian

Spanish

Portuguese

Page

World Wide Web URL

Online services

America Online

CompuServetm

Canada

Obtaining software utilities and electronic information

Asia-Pacific countries/regions

Australia, New Zealand, and India

HP service information

HP direct ordering for accessories or supplies

HP Support Assistant compact disc

HP SupportPack

Page

Worldwide sales and service offices

Denmark Greece

Czech Republic Germany

Far East Region Hungary

India

Latin American Headquarters

Korea New Zealand

Norway

México

Sweden

Spain

Switzerland

Taiwan

Service and support

131

Printer specifications

Printer specifications Environmental specifications

Specifications

Electrical specifications

Acoustics

Printer capacities and ratings

Printer specifications Physical specifications

FCC compliance

Protecting the Environment

Environmental Product Stewardship Program

This HP LaserJet printer eliminates

This HP LaserJet printer design reduces

Plastics

HP Cartridge Recycling Program information

HP toner cartridges

Paper

Material safety data sheet

Declaration of Conformity

Regulatory statements

Laser safety statement

Canadian DOC regulations

Korean EMI statement

Laserturvallisuus Luokan 1 Laserlaite Klass 1 Laser Apparat

Laser statement for Finland

141

Scannerspecifications

Specifications

Printer capacities and ratings

Appendix B Scanner specifications

FCC compliance

Design of this HP scanner facilitates the recycling

Environmental product stewardship

Regulatory statements

Laser safety statement

Laser statement for Finland

Appendix B Scanner specifications

151

Paper specifications

Supported paper sizes printer

Printer paper specifications

Symptom Problem with Paper Solution

Guidelines for using paper

Labels

Transparencies

Label construction

Envelopes

Envelope construction

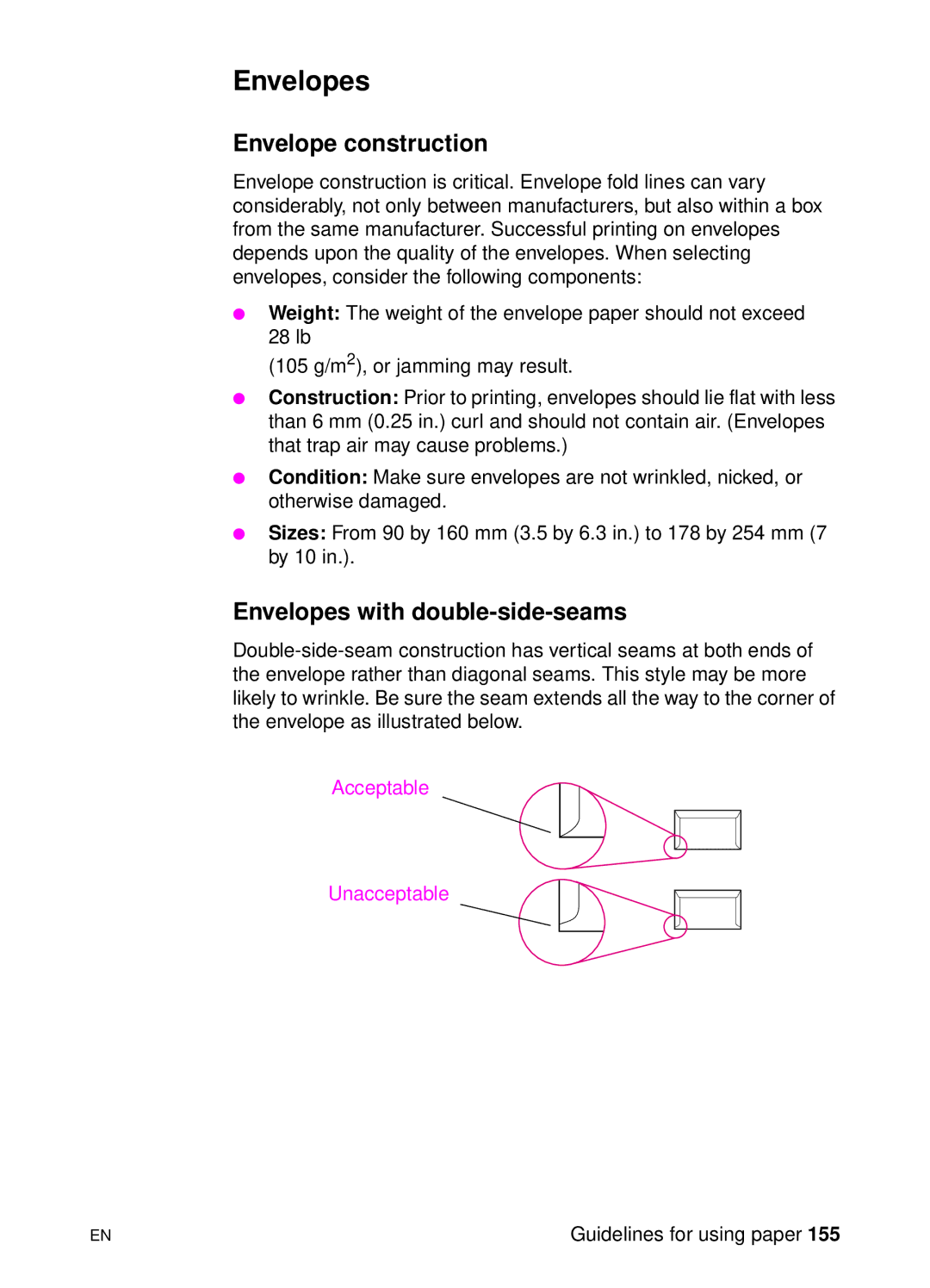

Envelopes with double-side-seams

Envelope storage

Envelopes with adhesive strips or flaps

Card stock and heavy media

Card stock construction

Card stock guidelines

Appendix C Paper specifications

159

Memory DIMMs

Installing DIMMs memory

Page

Test Dimm installation

Removing DIMMs

Appendix D Memory DIMMs

165

Warrantylicensing

HP Software License Terms

Hewlett-Packard software license agreement

Page

Hewlett-Packard limited warranty statement

Hewlett-Packard limited warranty statement

How do I know when the HP toner is running out?

Limited warranty for toner cartridge life

What does this warranty not cover?

How long does the coverage last?

How does State, Province or Country Law apply?

How do I return the faulty cartridge?

Appendix E Warranty and licensing

Accessories

Ordering information

173

Memory

Ordering information Description or Use Order Number

175

Ordering information Description or Use Order Number

Appendix F Accessories and ordering information

177

Scanner resolution and gray scale

Overview

Resolution and gray-scale guidelines

76 x 127 mm 150 dpi 152 x 254 mm 300 dpi

Resolution

Gray scale

Usage table Uses for 1 bit setting Uses for 8 bit setting

Appendix G Scanner resolution and gray scale

Index

Index

OCR

Index

Index

Page

C4218-90962