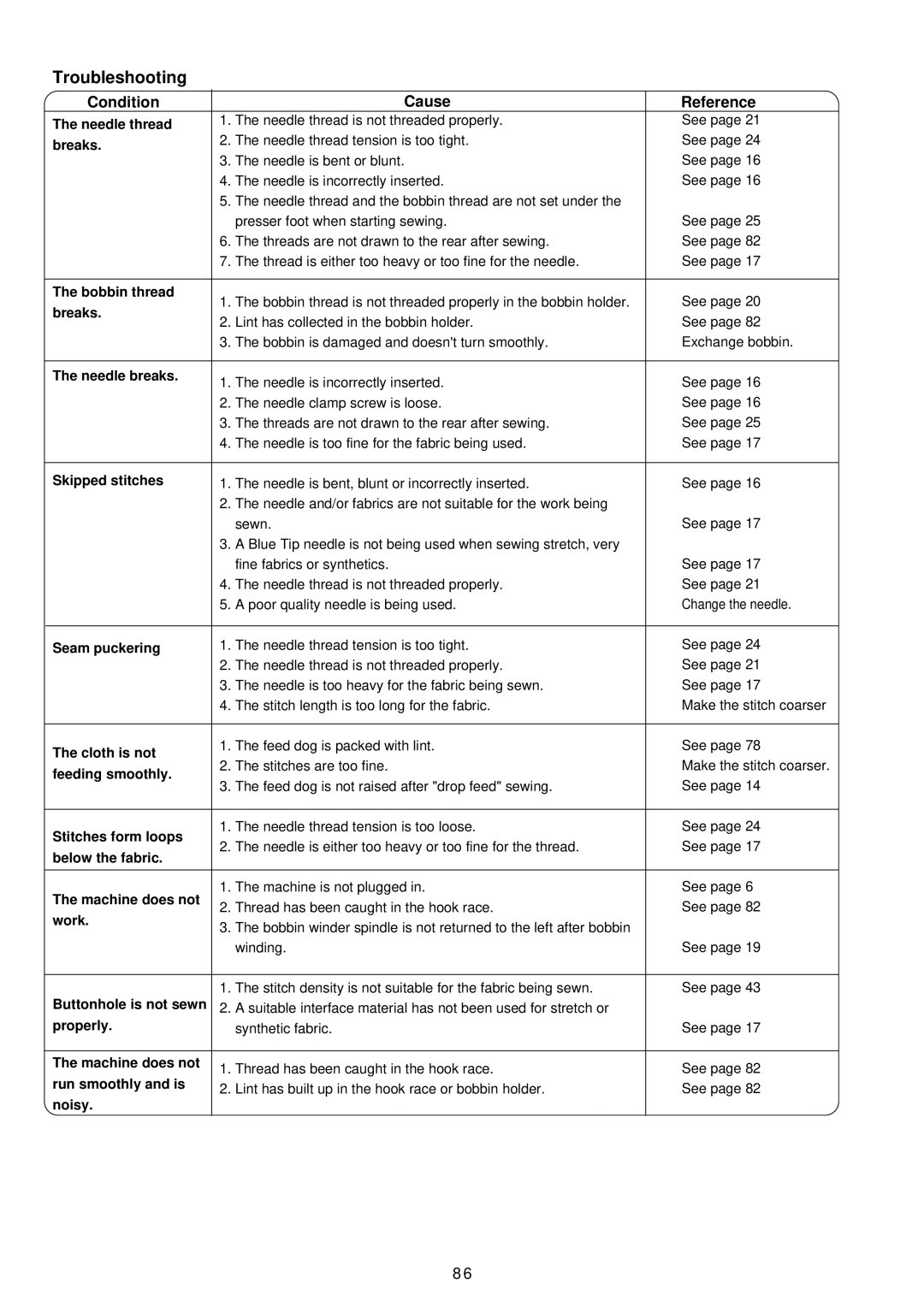

Troubleshooting

Condition |

| Cause | Reference | |

The needle thread | 1. The needle thread is not threaded properly. | See page 21 | ||

breaks. | 2. | The needle thread tension is too tight. | See page 24 | |

3. | The needle is bent or blunt. | See page 16 | ||

| ||||

| 4. | The needle is incorrectly inserted. | See page 16 | |

| 5. | The needle thread and the bobbin thread are not set under the |

| |

|

| presser foot when starting sewing. | See page 25 | |

| 6. | The threads are not drawn to the rear after sewing. | See page 82 | |

| 7. | The thread is either too heavy or too fine for the needle. | See page 17 | |

|

|

|

| |

The bobbin thread | 1. | The bobbin thread is not threaded properly in the bobbin holder. | See page 20 | |

breaks. | ||||

2. | Lint has collected in the bobbin holder. | See page 82 | ||

| ||||

| 3. | The bobbin is damaged and doesn't turn smoothly. | Exchange bobbin. | |

|

|

|

| |

The needle breaks. | 1. | The needle is incorrectly inserted. | See page 16 | |

| ||||

| 2. | The needle clamp screw is loose. | See page 16 | |

| 3. | The threads are not drawn to the rear after sewing. | See page 25 | |

| 4. | The needle is too fine for the fabric being used. | See page 17 | |

|

|

| ||

Skipped stitches | 1. The needle is bent, blunt or incorrectly inserted. | See page 16 | ||

| 2. | The needle and/or fabrics are not suitable for the work being |

| |

|

| sewn. | See page 17 | |

| 3. | A Blue Tip needle is not being used when sewing stretch, very |

| |

|

| fine fabrics or synthetics. | See page 17 | |

| 4. | The needle thread is not threaded properly. | See page 21 | |

| 5. | A poor quality needle is being used. | Change the needle. | |

|

|

| ||

Seam puckering | 1. The needle thread tension is too tight. | See page 24 | ||

| 2. | The needle thread is not threaded properly. | See page 21 | |

| 3. | The needle is too heavy for the fabric being sewn. | See page 17 | |

| 4. | The stitch length is too long for the fabric. | Make the stitch coarser | |

|

|

|

| |

The cloth is not | 1. | The feed dog is packed with lint. | See page 78 | |

2. | The stitches are too fine. | Make the stitch coarser. | ||

feeding smoothly. | ||||

3. | The feed dog is not raised after "drop feed" sewing. | See page 14 | ||

| ||||

|

|

|

| |

Stitches form loops | 1. | The needle thread tension is too loose. | See page 24 | |

2. | The needle is either too heavy or too fine for the thread. | See page 17 | ||

below the fabric. | ||||

|

|

| ||

|

|

| ||

The machine does not | 1. The machine is not plugged in. | See page 6 | ||

2. | Thread has been caught in the hook race. | See page 82 | ||

work. | ||||

3. | The bobbin winder spindle is not returned to the left after bobbin |

| ||

|

| |||

|

| winding. | See page 19 | |

|

|

|

| |

Buttonhole is not sewn | 1. | The stitch density is not suitable for the fabric being sewn. | See page 43 | |

2. A suitable interface material has not been used for stretch or |

| |||

properly. |

| synthetic fabric. | See page 17 | |

|

|

|

| |

The machine does not | 1. | Thread has been caught in the hook race. | See page 82 | |

run smoothly and is | ||||

2. | Lint has built up in the hook race or bobbin holder. | See page 82 | ||

noisy. | ||||

|

|

| ||

|

|

|

| |

8 6