FS-1900

Regarding Tradenames

License

Limited Warranty

Limitation of Remedies

General

Agfa Japan License Agreement

Typeface Trademark Acknowledgement

Contents

Contents

Maintenance

Paper Selection

Chapter

Fonts Options

Troubleshooting

Appendix C Host Computer Interface

Appendix a Appendix B

Glossary Glossary-1 Index Index-1

Introduction

Features

Wide Variety of Available Fonts

Prescribe Command Language

Job Retention

Display of printer messages in any of five languages

Guide to the Operation Guide

For More Information

Appendix B Options

Appendix D Specifications

Appendix C Host Computer Interface

Glossary

Using the Operator Panel

Understanding the Operator Panel

Message Display

Message Meaning

Interface Indicator

Paper Size Indicator

Message Paper Size Display

READY, DATA, and Attention Indicators

Paper Type Indicator

Indicator Description

Message Display Paper Type

Key Function

Keys

Menu System Road Map

Over operator panel settings

TCP/IP

IBM

Understanding the Operator Panel

Heavy Thick Light Thin Duplex Path Enable Disable

Understanding the Operator Panel

Menu Map

Printing Test Pages

Print Menu Map

Print Menu Map ?

Sample Menu MAP

Menu MAP

Status

Print Status

Print Status Page ?

Status

Error Log

Installation Options

Software Version

Hardware Information

KIR Test Pattern

Interface Information

Service Status

Service

Others

Network Card Interface Status

Opt. StatusPage ? On

Opt. StatusPage ? Off

Font

Font Lists

Font Select Internal

List

Font Lists

Print HEX-DUMP

Received Data Dumping

Print HEX-DUMP?

Processing Waiting

Setting the Paper Size

Setting the Paper Size in Paper Cassette

Paper Handling

Custom Paper Size

Paper Handling

Cassette Size

Unit

Unit ? mm

Dimension

Dimension 216 mm

Setting the Paper Size in MP Tray

MP Tray Size

MP Tray Size ? A4

Changes as shown below

Setting the Paper Type in Paper Cassette

Setting the Paper Type

Cassette Type Plain

Cassette Type ? Plain

Setting the Paper Type in MP Tray

MP Tray Type Plain

MP Tray Type ? Plain

Custom Paper Type

Type Adjust Custom

Paper Handling

Paper Weight Normal

Paper Weight ? Normal

Setting the Paper Weight

Duplex path Enable

Duplex path ? Enable

Setting the Duplex Path

Reset Type Adjust

Reset Type Adjust ?

Resetting the Custom Paper Type

MP Tray Mode Cassette

MP Tray Mode

Selecting the Paper Feed Source

MP Tray Mode ? Cassette

Feed Select Cassette

Feed Select ? Cassette

Output Stack

Stack Select Face-down tray

Stack Select

Overriding A4 and Letter Size Difference

Override A4/LT Off

Override A4/LT ? Off

Emulation

Pagination

Emulation ?PCL

Changing the Emulation

Emulation

Alt. Emulation ?PCL

Alternative Emulation for Kpdl Emulation

?KPDL

Printing Kpdl Errors

Default font

Print Kpdl Errs ? On

Font

I000

?I000

Letter Description

Default Font Size

Size Points

Size

Courier Regular

Courier ? Regular

Changing Type for Courier/Letter Gothic

Setting the Character Pitch for Courier/Letter Gothic

Pitch 10.00 cpi

Pitch

Code Set

Code Set

Code Set ?IBM PC-8

Number of Copies

Set

Copies 001

Printing Orientation

Orientation Portrait

Orientation ? Portrait

Status KIR Checking Lines

KIR Kyocera Image Refinement

KIR Mode

KIR Mode ? On

Print Quality

Ecoprint Mode Off

Ecoprint Mode ? Off

Ecoprint

Resolution

Resolution Fast 1200 mode

Resolution

MPS

Mode Quick Copy Proof and Hold Private Print Stored Job

Quick Copy

Printing Additional Copies using Quick Copy

MPS

Job Storage

Quick Copy

Quick Copy Harold

Quick Copy ?Arlen

Arlen ?Report

Proof and Hold

Report Delete

Deleting a Quick Copy Job

Printing Remaining Copies of a Proof and Hold Job

Quick Copy Harold

Private/Stored Harold

Printing a Private Job

Private/Stored ?Harold

Private/Stored ?Arlen

Agenda Copies

Agenda

Agenda Delete

Deleting a Private Job

Releasing a Stored Job

Storing a Print Job

Deleting a Stored Job

Agenda Copies 001

Finish

Printing a Code Job

MPS

Printing a List of Code Jobs

List Code JOB

List Code JOB ?

Retrieving Jobs from Virtual Mailbox VMB

Print VMB Data Tray001

Tray001?

Printing a List of VMB

List of VMB

List of VMB ?

MPS Configuration

MPS Configuration

Maximum Space Assigned to Temporary Code Jobs

Temp. Code JOB Size 050MB

Perm. Code JOB Size 050MB

Size 05 0MB

Maximum Space Assigned to Permanent Code Jobs

VMB Size 050MB

VMB Size

Maximum Space Assigned to Virtual Mailboxes

Interface

Parallel Interface Mode

USB Interface Mode

Parallel I/F

Interface

Interface ? Serial

Serial Interface Parameters

Lower the baud rate

Baud Rate

Network Interface Parameters

NetWare

EtherTalk Off Opt. StatusPage On

Range

Dhcp Off IP Address 000.000.000.000 Subnet Mask Gateway

RAM Disk Mode Off

Operating the Storage Device

Activating the RAM Disk

RAM Disk Mode ? On

RAM Disk Size Mbyte

Enter key

Memory Card

Reading Data

Read Data Data name

Read Data ?data name

Write Data

Writing Data

Write Data ?

Formatting a new Microdrive

Write Information

Deleting Data

Delete Data Data name

Delete Data ?data name

Reading Fonts from a CompactFlash Card

Read fonts

Read fonts ?

Formatting a Storage Device

Format

Format ?

List Partitions

Printing a List of Data Names

Partition List

List Partitions ?

Protect Mode

Configuration

Protect

Protect ? On

Linefeed LF Action

Protect ? Auto

LF Action LF only

LF Action ? LF only

Carriage-Return CR Action

CR Action CR only

CR Action ? CR only

Wide A4 Pitch

Wide A4 Off

Wide A4 ? Off

Print Density

Print Density

New Toner Installed

Toner Counter Resetting

Total Printed Pages

Life Counters

Message Language

New Toner Installed ?

MSG Language English

MSG Language ? English

Following order The key cycles in the reverse order

Form Feed

Automatic Form Feed Timeout

Sleep Timer Setting

Sleep Timer 015 min

Sleep Timer

Sleep Mode ? On

Sleep Mode

Sleep Mode ? Off

Turning Off the Sleep Timer

Printer Reset

Printer Resetting

Printer Reset ?

Self test Please wait Ready

Resource Protection

Resource Prot Off

Resource Prot ? Off

Alarm Buzzer Setting

Buzzer

Buzzer ? On

Auto Continue Setting

Auto Continue Mode On

Auto Continue Mode ? On

Setting the Auto Continue Recovery Time

Auto Continue Timer

Paper Selection

Specification

Paper Specifications

General Guidelines

Paper Availability

Selecting the Right Paper

Condition of the Paper

Composition

Paper Size

Basis Weight

Smoothness

Multi-purpose tray Size Cassette or multi Purpose tray

Moisture Content

Paper Weight Equivalence Table

Bond Weight lb Europe Metric

Weight g/m²

Other Paper Properties

Paper Grain

Special Paper

Transparency Overhead Projection Film

Paper type Media type

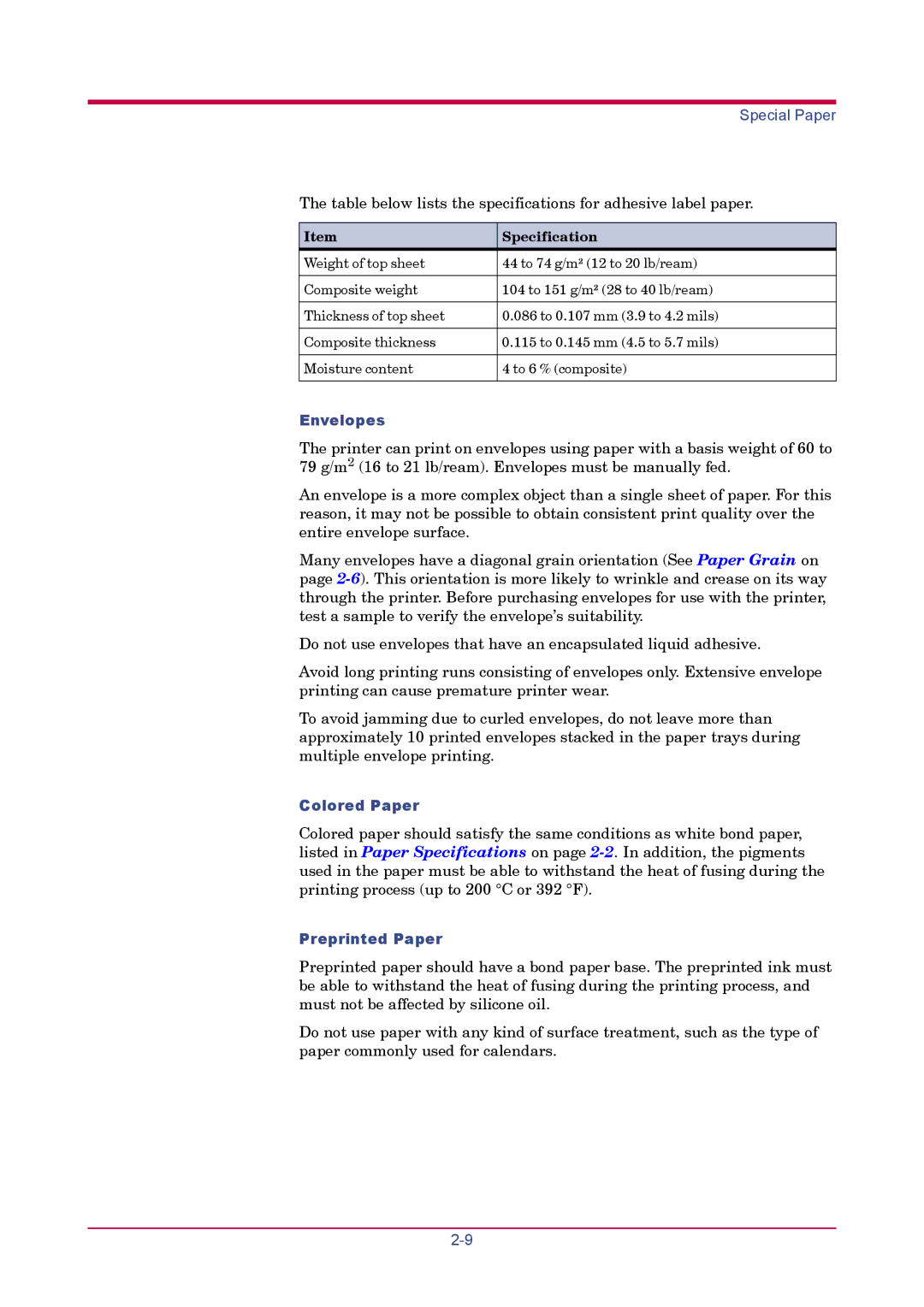

Adhesive-Backed Labels

Envelopes

Colored Paper

Preprinted Paper

Recycled Paper

Paper Type

Maintenance

Toner Container Replacement Interval

Toner Container Replacement

Keep the toner container as level as possible while removing

Replenishing Toner

Carefully remove the protective seal orange colored

Push Here

Replacing the Waste Toner Box

Waste Toner Box Replacement

Cap the waste toner box after removing from the printer

Toner Counter Resetting on

Cleaning the Charger Wire

Cleaning

Cleaning the Charger Grid

Cleaner is not re-usable

Paper Transfer Unit

Ramp using the wiper cloth included in the toner kit

Troubleshooting

General Guide

Symptom Check Items Corrective Action

Print Quality Problems

Check the charger unit installation

Check the Ecoprint setting

Check the operator panel

Check the print density

Check the paper chute and the ramp

Check the transfer roller

Check the file or program

Indicators and Messages

Indicators

Indicator Name Condition Description

Message Corrective Action

Maintenance Messages

Key. See Correcting a Paper Jam on

Hardware compatible with the FS-1900

See Operating the Storage Device on

Error Messages

From the operator panel, and re-select Auto

Beginning to ensure correct reading of the memory card

Paper jam Description Reference Message Location

Correcting a Paper Jam

Online help messages

Jam recovery

Jam at the Paper Cassette or Inside the Printer

Paper jam Cassette

Help Start -- Press ? key

Shown in B

Paper jam Duplexer Help Start -- Press ? key

Paper Jam at the Option Duplexer

Remove the jammed paper

Paper jam Sorter

Paper Jam at the Option Sorter

Close the rear cover of the option sorter

Paper jam MP tray

Jam at the MP Tray

Appendix a Fonts

PCL Scalable and Bitmap Fonts

List of Fonts

Font Number Font samples

Font Number Font samples

Kpdl Fonts

Kpdl Fonts

Appendix B Options

Other Options

Available Options

Expanding the Printer Memory

Following instructions are intended for the technician only

Removing the Main Circuit Board

Circuit board, can cause serious damage to the printer

Dimm to be used

Installing Dimm

Removing Dimm

Testing the Expansion Memory

Adjusting the Memory on the Printer Driver

PF-60 Paper Feeder

Installing Option Units

Installing Option Units

Load paper

DU-60 Duplexer

Gently place the printer on top of the duplexer

Pass the connected cable and power cord through the opening

SO-60 Sorter

Cord, and printer cable

Push the sorter down. The levers of the attachment legs are

Grip

Duplexer Rear Cover

Do not move or lift the printer with the sorter installed

EF-60 Envelope Feeder

Installing the envelope feeder on the printer

Load envelopes into the envelope feeder

Pull out the sub-tray that matches the size of the envelopes

Paper Setting Button

PT-4/PT-60 Face-up Output Tray

Install the face-up output tray on the rear of the printer

Network Interface Card

About the modes, see Network Interface Parameters on

Microdrive Hard Disk

Return the main circuit board to the printer by reversing

Result in the printer’s electronics or the CompactFlash card

CompactFlash Memory Card

Appendix C Host Computer Interface

Interface Signals

Parallel Interface

Parallel Interface Communication Modes

Pin In/out Description

Parallel Connector Pin Assignment

Acknowledge* nAck Pin

USB Interface

Specifications

Pin In/out Signal Description

Interface Signals

Serial Interface Option

RS-232C Interface

RS-422A Interface

SG Signal Ground Pin

Overview of Signals RS-422A

Serial Connector

RS-422A Interface Voltage Levels

RS-232C/RS-422A Protocol

Parameter value Baud rate

Parameter value Meaning

Serial interface error

Prescribe Frpo D0 Command

Error not handled Error handled

RS-422A interface

Connecting the Printer to the Computer

RS-232C Cable Connection

Obtain a Suitable RS-232C Cable

RS-232C Cable Connection

DOS, enter the following commands

Appendix D Specifications

Drum cleaning

Resolution

Printing method

Printing speed

Power consumption

Power requirements

Pressure level at the front Dimensions

Operating noise

Glossary

First mode

Cassette mode

Dpi dots per inch

Ecoprint Emulation

MP tray

Sleep mode

Offline

Online

Index

Index-2

Index-3

2002.2EC

For FS-1900

Regarding Tradenames

Preface

Contents

Using Parallel Interface

Installing the Printer Driver

Run. Type the following in the Command Line text box

Window appears

Select a device model window, click FS-1900

Options Click the Next button

Device connection window, select the type of connection

Installing the Printer Driver

Printers window

Confirming the Installation

Installing the Printer Driver

Installing the USB Printing Support

Using USB Interface

Automatic search for a better driver

Installing the Printer Driver for USB

USB 001 Virtual printer port for USB is following port list

Printers window Right click the Kyocera Mita FS-1900 KX

Installing the Paper Feeder PF-60

Click the Device Settings tab

Adding Optional Devices

Adding Optional Devices

Installing the Duplexer DU-60

Properties

Click Duplex Unit in the Device Options list box

Click Sorter Stacker in the Device Options list box

Installing the Sorter SO-60

Click Envelope Feeder in the Device Options list box

Installing the Envelope Feeder EF-60

Installing the Microdrive Hard Disk

Click the Device Settings tab

Drop down list, and click the OK button

Printing from Windows Applications

Basic Printing Task

Number of Copies combo box

Printing from Windows Applications

Properties click the Media tab

To set the custom size

Customized Paper Sizes list

Device Settings tab

Cover Mode

Advanced Media Settings

Back

Not applicable for model FS-1900

Insert

You select this check box

Transparency from the Media Type list

Transparency Interleaving

Click the Transparency Interleaving check box

Printing Multiple Pages per Sheet

Changing the Size of the Document

If you want to set Resolution, Kyocera Image Refinement,

Changing the Resolution

Text is unaffected by the Grayscale Adjustment settings

Adjusting Grayscale

TrueType Fonts

Watermark Printing

Only on specified pages for Page Specification

Using the Duplexer DU-60

Display the printer driver’s Properties dialog box from

Using the Sorter SO-60

Printing from Windows Applications

Sorter modes

Sorter Mode Description

MPS

Code Job Temporary and Permanent

Virtual Mail Box

Using Job Retention Quick Copy Printing

Copy

Proof and Hold Printing

Hold

Private Printing

Private Print

Stored Job Printing Job Storage

Storage

Virtual Mailbox Printing

Before Using Virtual Mailboxes

Down list, and click the OK button

Settings dialog box will be displayed

Using VMB Printing

Names

Mail Box VMB

Printing a Code Job

Microdrive as it is printed

2002.2EC