BRAZING

CONNECTIONS

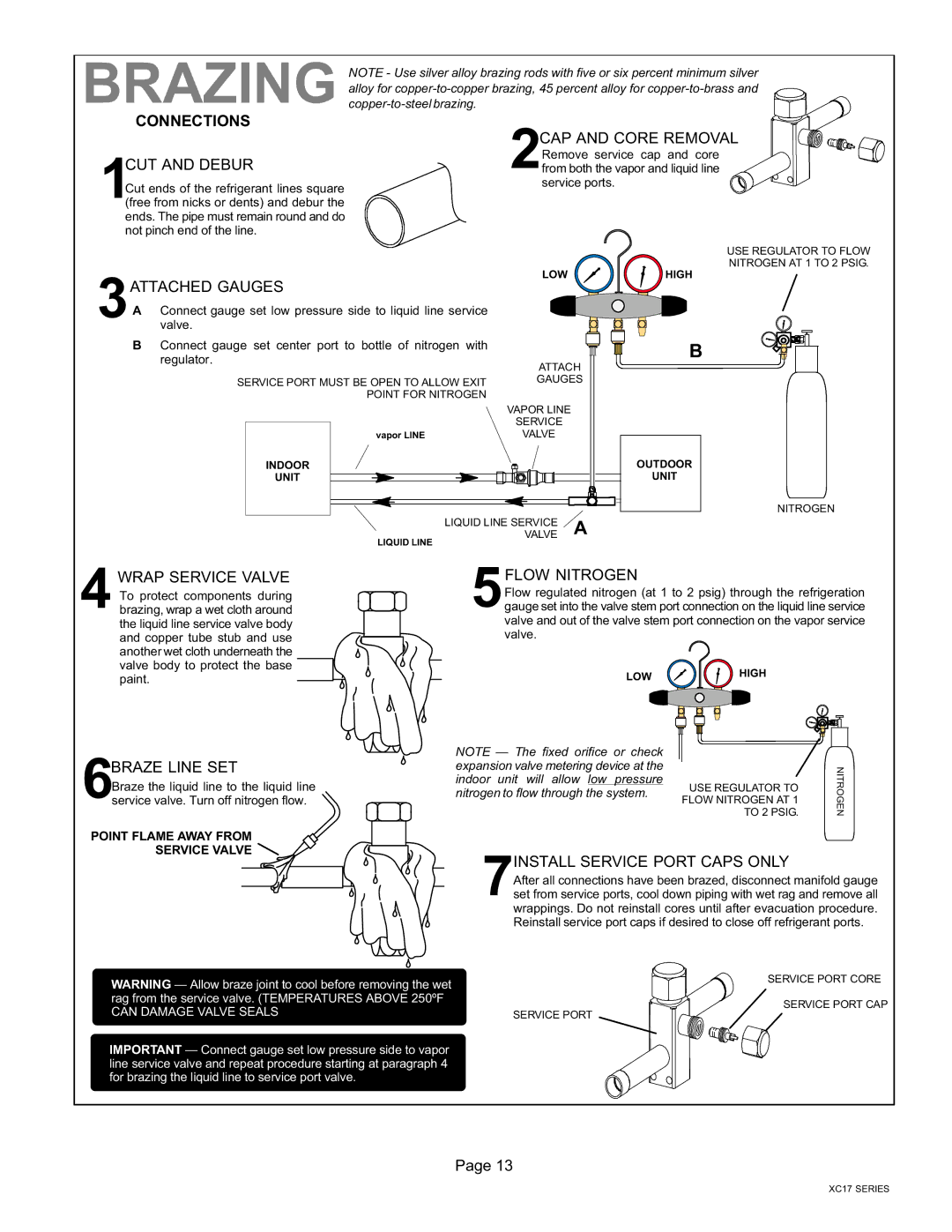

1CUT AND DEBUR

Cut ends of the refrigerant lines square (free from nicks or dents) and debur the ends. The pipe must remain round and do not pinch end of the line.

NOTE − Use silver alloy brazing rods with five or six percent minimum silver alloy for copper−to−copper brazing, 45 percent alloy for copper−to−brass and copper−to−steel brazing.

2CAP AND CORE REMOVAL Remove service cap and core from both the vapor and liquid line service ports.![]()

![]()

![]()

LOW

3 | ATTACHED GAUGES |

|

|

|

| ||

A Connect gauge set low pressure side to liquid line service |

|

|

|

| |||

|

|

|

| ||||

valve. |

|

|

|

| |||

| B Connect gauge set center port to bottle of nitrogen with |

|

|

|

| ||

| regulator. | ATTACH | |||||

|

|

|

| ||||

| SERVICE PORT MUST BE OPEN TO ALLOW EXIT | GAUGES | |||||

|

|

|

|

| |||

|

|

| POINT FOR NITROGEN |

|

|

|

|

|

|

|

| VAPOR LINE | |||

|

|

|

| SERVICE | |||

|

|

|

| ||||

|

|

| vapor LINE | VALVE | |||

INDOOR

UNIT

LIQUID LINE SERVICEVALVE A

LIQUID LINE

USE REGULATOR TO FLOW

NITROGEN AT 1 TO 2 PSIG.

HIGH

B

OUTDOOR

UNIT

NITROGEN

4WRAP SERVICE VALVETo protect components during

brazing, wrap a wet cloth around the liquid line service valve body and copper tube stub and use another wet cloth underneath the valve body to protect the base paint.

6BRAZE LINE SET

Braze the liquid line to the liquid line service valve. Turn off nitrogen flow.

POINT FLAME AWAY FROM

SERVICE VALVE ![]()

5FLOW NITROGEN

Flow regulated nitrogen (at 1 to 2 psig) through the refrigeration gauge set into the valve stem port connection on the liquid line service valve and out of the valve stem port connection on the vapor service valve.

LOW | HIGH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

expansion valve metering device at the |

|

| TO 2 PSIG. |

| NITROGEN | ||

indoor unit will allow low pressure |

|

|

| ||||

USE REGULATOR TO |

|

|

| ||||

nitrogen to flow through the system. |

|

|

| ||||

FLOW NITROGEN AT 1 |

|

|

| ||||

|

|

|

| ||||

|

|

|

|

|

|

|

|

7INSTALL SERVICE PORT CAPS ONLY

After all connections have been brazed, disconnect manifold gauge set from service ports, cool down piping with wet rag and remove all wrappings. Do not reinstall cores until after evacuation procedure. Reinstall service port caps if desired to close off refrigerant ports.

WARNING

rag from the service valve. (TEMPERATURES ABOVE 250ºF

CAN DAMAGE VALVE SEALS

IMPORTANT

line service valve and repeat procedure starting at paragraph 4 for brazing the liquid line to service port valve.

SERVICE PORT

SERVICE PORT CORE

SERVICE PORT CAP

Page 13

XC17 SERIES