Venting Practices

The thickness of construction through which vent pipes may be installed is 24" (610mm) maximum and 3" (76mm) minimum. If a G61MP furnace replaces a furnace which was commonly vented with another gas appliance, the size of the existing vent pipe for that gas appliance must be checked. Without the heat of the original furnace flue prod- ucts, the existing vent pipe is probably oversized for the single water heater or other appliance. The vent should be checked for proper draw with the remaining appliance.

1 − Use recommended piping materials for exhaust pip- ing.

2 − Secure all joints so that they are

Suspend piping using hangers at a minimum of every 5 feet (1.52m) for schedule

40 PVC and every 3 feet

(.91m) for ABS−DWV, PVC− DWV, SPR−21 PVC, and SDR−26 PVC piping. A suit- able hanger can be fabri- cated by using metal or

plastic strapping or a large wire tie.

3 − In areas where piping penetrates joists or interior walls, hole must be large enough to allow clearance on all sides of pipe through center of hole using a hanger.

4 − Isolate piping at the point where it exits the outside wall or roof in order to prevent transmission of vibration to the structure.

5 − When furnace is installed in a residence where unit is shut down for an extended period of time, such as a vacation home, make provisions for draining conden- sate collection trap and lines.

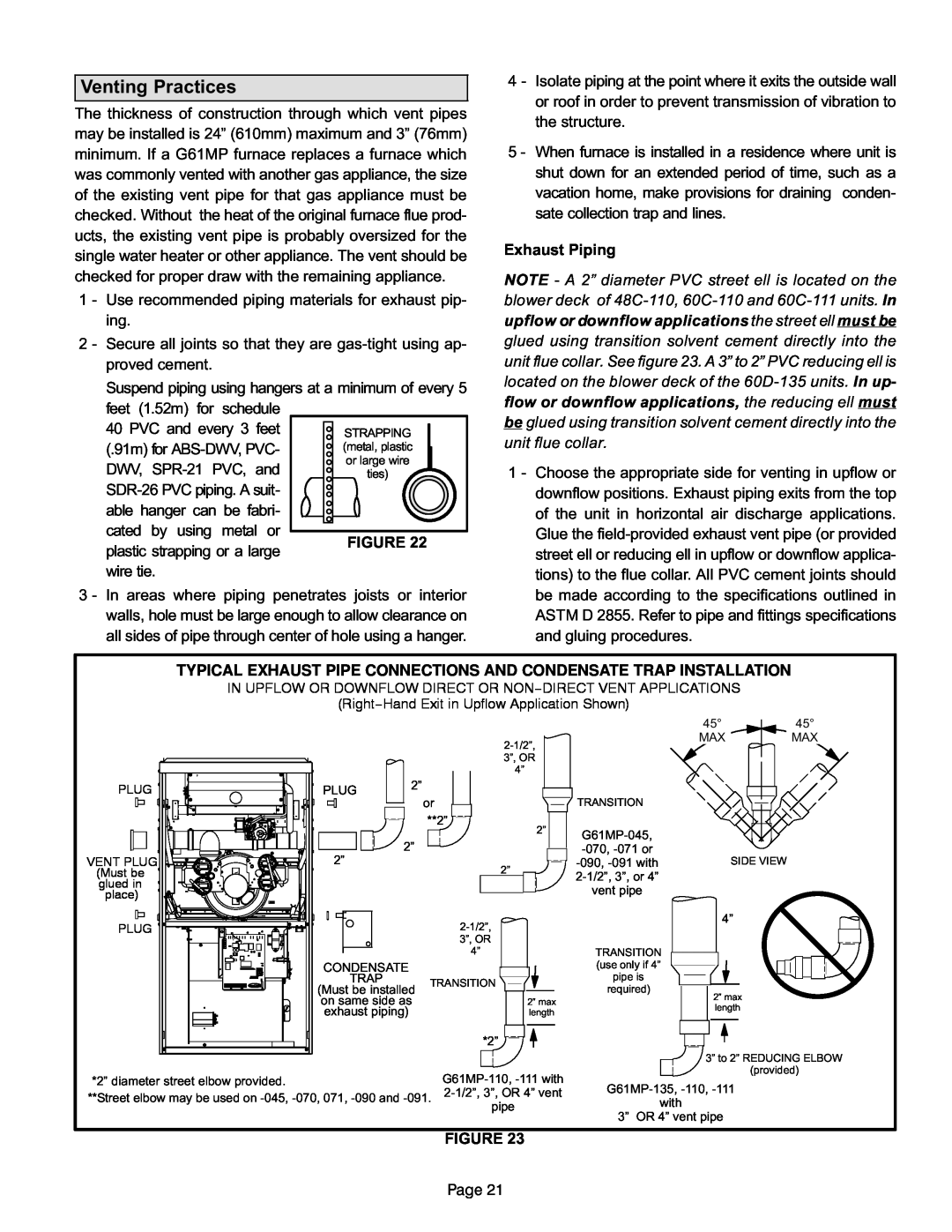

Exhaust Piping

NOTE − A 2" diameter PVC street ell is located on the blower deck of 48C−110, 60C−110 and 60C−111 units. In upflow or downflow applications the street ell must be glued using transition solvent cement directly into the unit flue collar. See figure 23. A 3" to 2" PVC reducing ell is located on the blower deck of the 60D−135 units. In up- flow or downflow applications, the reducing ell must be glued using transition solvent cement directly into the unit flue collar.

1 − Choose the appropriate side for venting in upflow or downflow positions. Exhaust piping exits from the top of the unit in horizontal air discharge applications. Glue the field−provided exhaust vent pipe (or provided street ell or reducing ell in upflow or downflow applica- tions) to the flue collar. All PVC cement joints should be made according to the specifications outlined in ASTM D 2855. Refer to pipe and fittings specifications and gluing procedures.

TYPICAL EXHAUST PIPE CONNECTIONS AND CONDENSATE TRAP INSTALLATION

IN UPFLOW OR DOWNFLOW DIRECT OR NON−DIRECT VENT APPLICATIONS

(Right−Hand Exit in Upflow Application Shown)

|

|

|

|

| 45° | 45° |

|

|

|

| 2−1/2", | MAX | MAX |

|

|

|

|

|

| |

|

|

|

| 3", OR |

|

|

|

|

|

| 4" |

|

|

PLUG | PLUG | 2" |

|

|

|

|

|

|

| or |

| TRANSITION |

|

|

|

| **2" | 2" |

|

|

|

|

|

| G61MP−045, |

| |

| 2" |

|

|

| ||

VENT PLUG |

|

| −070, −071 or |

| ||

2" |

|

|

| −090, −091 with | SIDE VIEW | |

(Must be |

|

|

| 2" | 2−1/2", 3", or 4" |

|

glued in |

|

|

|

|

| |

|

|

|

| vent pipe |

| |

place) |

|

|

|

|

| |

PLUG |

|

| 2−1/2", |

| 4" | |

|

|

|

|

| ||

|

|

| 3", OR |

|

|

|

|

|

| 4" |

| TRANSITION |

|

| CONDENSATE |

|

|

| (use only if 4" |

|

| TRAP |

| TRANSITION |

| pipe is |

|

| (Must be installed |

| required) |

| ||

|

|

|

| |||

| on same side as |

| 2" max | 2" max | ||

|

| length | ||||

| exhaust piping) |

|

| length | ||

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| *2" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3" to 2" REDUCING ELBOW | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

*2" diameter street elbow provided. | G61MP−110, −111 with |

|

|

|

|

|

|

|

|

|

|

|

|

| (provided) | ||||||||||||||||||||||||

G61MP−135, −110, −111 | |||||||||||||||||||||||||||||||||||||||

**Street elbow may be used on −045, −070, 071, −090 and −091. | 2−1/2", 3", OR 4" vent | ||||||||||||||||||||||||||||||||||||||

with | |||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| pipe | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3" OR 4" vent pipe | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||

FIGURE 23

Page 21