OPERATION

RANGER 9 OPERATION

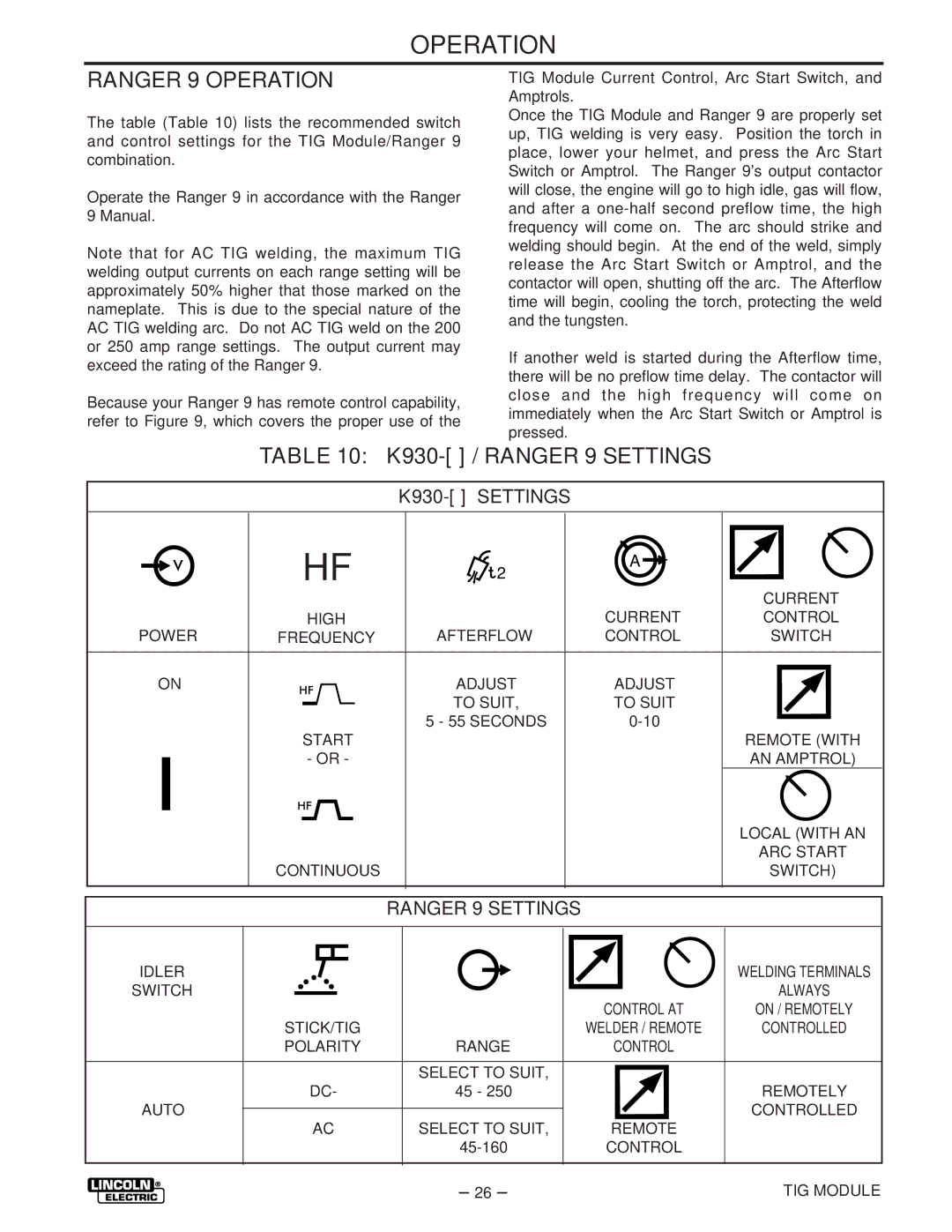

The table (Table 10) lists the recommended switch and control settings for the TIG Module/Ranger 9 combination.

Operate the Ranger 9 in accordance with the Ranger 9 Manual.

Note that for AC TIG welding, the maximum TIG welding output currents on each range setting will be approximately 50% higher that those marked on the nameplate. This is due to the special nature of the AC TIG welding arc. Do not AC TIG weld on the 200 or 250 amp range settings. The output current may exceed the rating of the Ranger 9.

Because your Ranger 9 has remote control capability, refer to Figure 9, which covers the proper use of the

TIG Module Current Control, Arc Start Switch, and Amptrols.

Once the TIG Module and Ranger 9 are properly set up, TIG welding is very easy. Position the torch in place, lower your helmet, and press the Arc Start Switch or Amptrol. The Ranger 9’s output contactor will close, the engine will go to high idle, gas will flow, and after a

If another weld is started during the Afterflow time, there will be no preflow time delay. The contactor will close and the high frequency will come on immediately when the Arc Start Switch or Amptrol is pressed.

TABLE 10: K930-[ ] / RANGER 9 SETTINGS

K930-[ ] SETTINGS

|

|

|

| HF |

|

| 2 |

|

| A |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CURRENT |

| |||

|

|

|

| HIGH |

|

|

| CURRENT | CONTROL |

| ||||||||

| POWER | FREQUENCY | AFTERFLOW | CONTROL | SWITCH |

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ON |

|

|

|

| ADJUST |

| ADJUST |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| TO SUIT, |

| TO SUIT |

|

|

|

|

| ||||

|

|

|

|

|

|

| 5 - 55 SECONDS |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

| START | REMOTE (WITH |

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

| - OR - |

|

|

|

|

|

|

| AN AMPTROL) |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LOCAL (WITH AN |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ARC START |

| ||

|

|

|

|

|

| CONTINUOUS |

|

|

|

|

|

|

|

|

| SWITCH) |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RANGER 9 SETTINGS |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

| IDLER |

|

|

|

|

|

|

|

|

|

|

|

|

|

| WELDING TERMINALS |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ALWAYS |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

| STICK/TIG |

|

|

|

|

| CONTROL AT | ON / REMOTELY |

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| WELDER / REMOTE | CONTROLLED |

|

| |||||||||

|

|

|

|

|

| POLARITY |

| RANGE |

|

| CONTROL |

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SELECT TO SUIT, |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| DC- |

| 45 - 250 |

|

|

|

|

|

| REMOTELY |

|

| ||||

|

|

| AUTO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CONTROLLED |

|

| ||

|

|

|

| AC |

| SELECT TO SUIT, |

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| REMOTE |

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| CONTROL |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| – 26 – |

|

|

|

| TIG MODULE |

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||