OPERATION

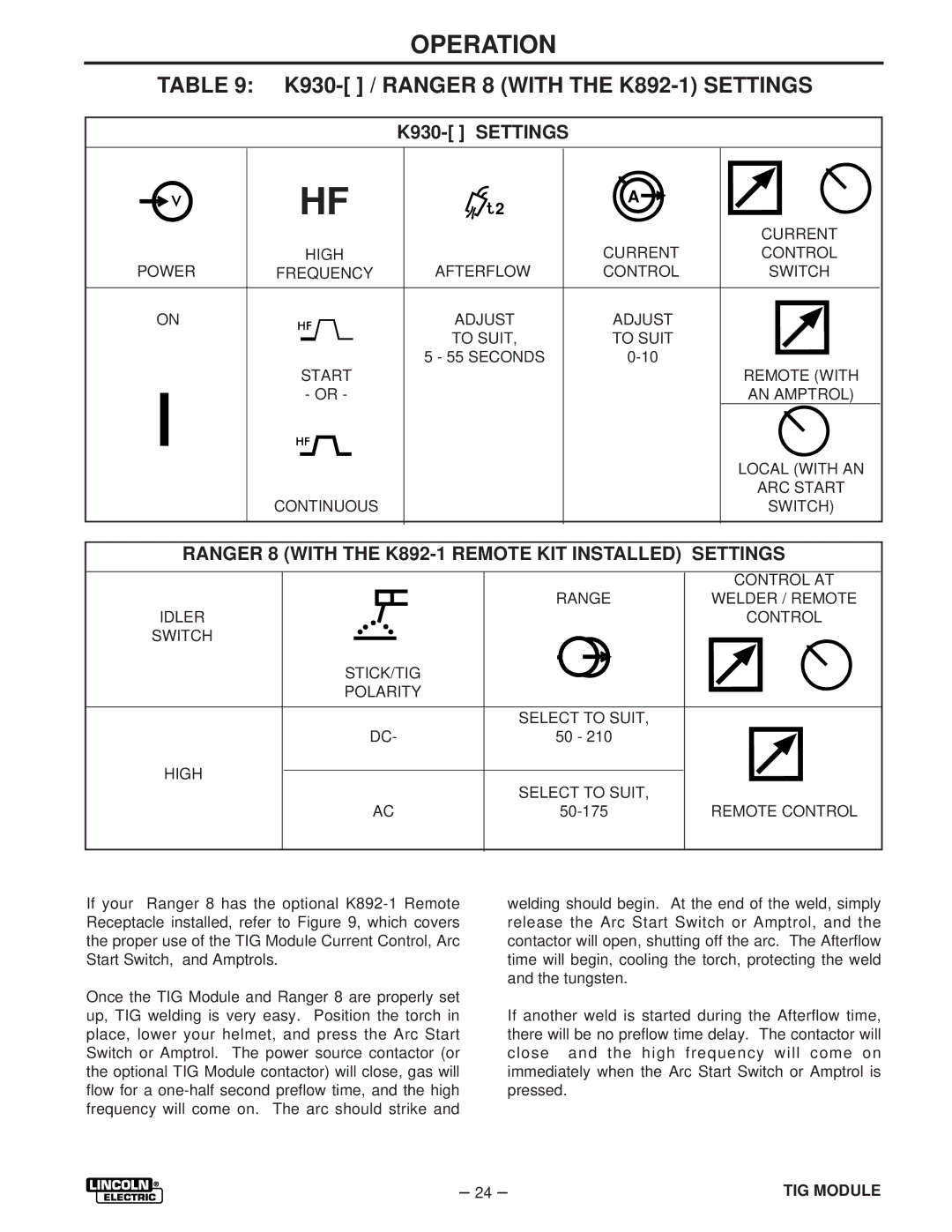

TABLE 9: K930-[ ] / RANGER 8 (WITH THE K892-1) SETTINGS

K930-[ ] SETTINGS

|

|

|

| HF |

|

| 2 |

|

| A |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| CURRENT |

| |||

|

|

|

| HIGH |

|

|

| CURRENT | CONTROL |

| ||||||||

| POWER | FREQUENCY | AFTERFLOW | CONTROL | SWITCH |

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ON |

|

|

|

| ADJUST |

| ADJUST |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| TO SUIT, |

| TO SUIT |

|

|

|

|

| ||||

|

|

|

|

|

|

| 5 - 55 SECONDS |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

| START | REMOTE (WITH |

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

| - OR - |

|

|

|

|

|

|

| AN AMPTROL) |

| |||||

|

|

|

|

|

|

|

|

|

| LOCAL (WITH AN | |||||

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| ARC START | ||||

| CONTINUOUS |

|

|

|

| SWITCH) | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| RANGER 8 (WITH THE |

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| CONTROL AT |

|

| |||

|

|

|

|

|

|

|

| RANGE |

| WELDER / REMOTE |

|

| |||

| IDLER |

|

|

|

|

|

| CONTROL |

| ||||||

| SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STICK/TIG |

|

|

|

|

|

|

|

| |||

|

|

|

| POLARITY |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SELECT TO SUIT, |

|

|

|

|

|

|

|

|

|

|

|

|

| DC- | 50 - 210 |

|

|

|

|

|

|

| |

| HIGH |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| SELECT TO SUIT, |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| AC |

| REMOTE CONTROL |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If your Ranger 8 has the optional

Once the TIG Module and Ranger 8 are properly set up, TIG welding is very easy. Position the torch in place, lower your helmet, and press the Arc Start Switch or Amptrol. The power source contactor (or the optional TIG Module contactor) will close, gas will flow for a

welding should begin. At the end of the weld, simply release the Arc Start Switch or Amptrol, and the contactor will open, shutting off the arc. The Afterflow time will begin, cooling the torch, protecting the weld and the tungsten.

If another weld is started during the Afterflow time, there will be no preflow time delay. The contactor will close and the high frequency will come on immediately when the Arc Start Switch or Amptrol is pressed.

– 24 – | TIG MODULE |