TIG MODULE

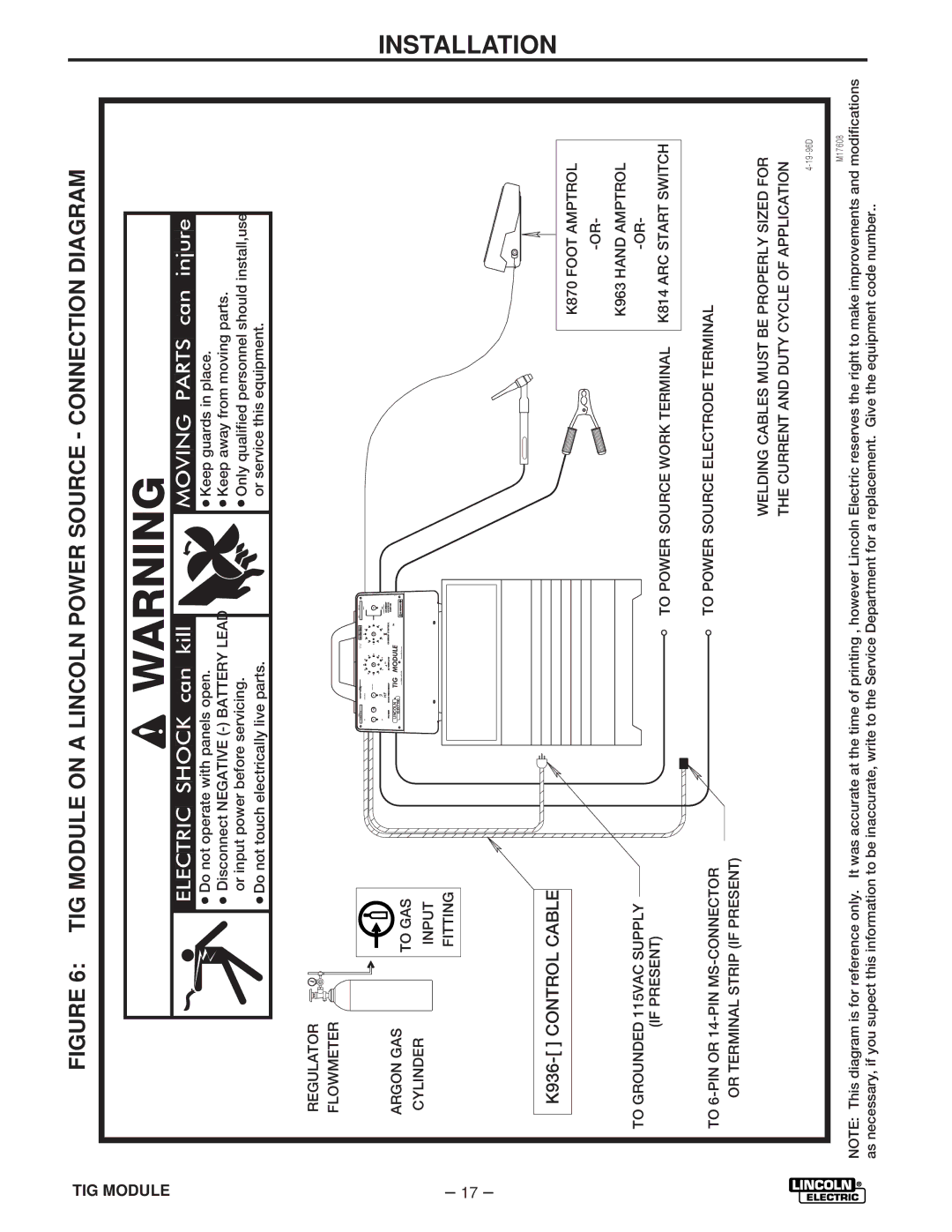

FIGURE 6: TIG MODULE ON A LINCOLN POWER SOURCE - CONNECTION DIAGRAM

![]() WARNING

WARNING

![]() Do not operate with panels open.

Do not operate with panels open.

![]() Disconnect NEGATIVE

Disconnect NEGATIVE

![]() Do not touch electrically live parts.

Do not touch electrically live parts.

REGULATOR

FLOWMETER

![]() Keep guards in place.

Keep guards in place.

![]() Keep away from moving parts.

Keep away from moving parts.

![]() Only qualified personnel should install,use or service this equipment.

Only qualified personnel should install,use or service this equipment.

– 17 –

ARGON GAS | TO GAS | |

CYLINDER | ||

INPUT | ||

| ||

| FITTING |

K936-[ ] CONTROL CABLE

TO GROUNDED 115VAC SUPPLY (IF PRESENT)

TO

| O |

|

|

|

| HF |

|

| CURRENT |

POWER | HIGH FREQUENCY | AFTERFLOW | CURRENT CONTROL | CONTROL |

|

|

|

| SWITCH |

LINCOLN |

|

|

| |

ELECTRIC |

|

| WARNING | |

K870 FOOT AMPTROL

K963 HAND AMPTROL

TO POWER SOURCE WORK TERMINAL K814 ARC START SWITCH

TO POWER SOURCE ELECTRODE TERMINAL

INSTALLATION

WELDING CABLES MUST BE PROPERLY SIZED FOR

THE CURRENT AND DUTY CYCLE OF APPLICATION

M17608

NOTE: This diagram is for reference only. It was accurate at the time of printing , however Lincoln Electric reserves the right to make improvements and modifications as necessary, if you supect this information to be inaccurate, write to the Service Department for a replacement. Give the equipment code number..