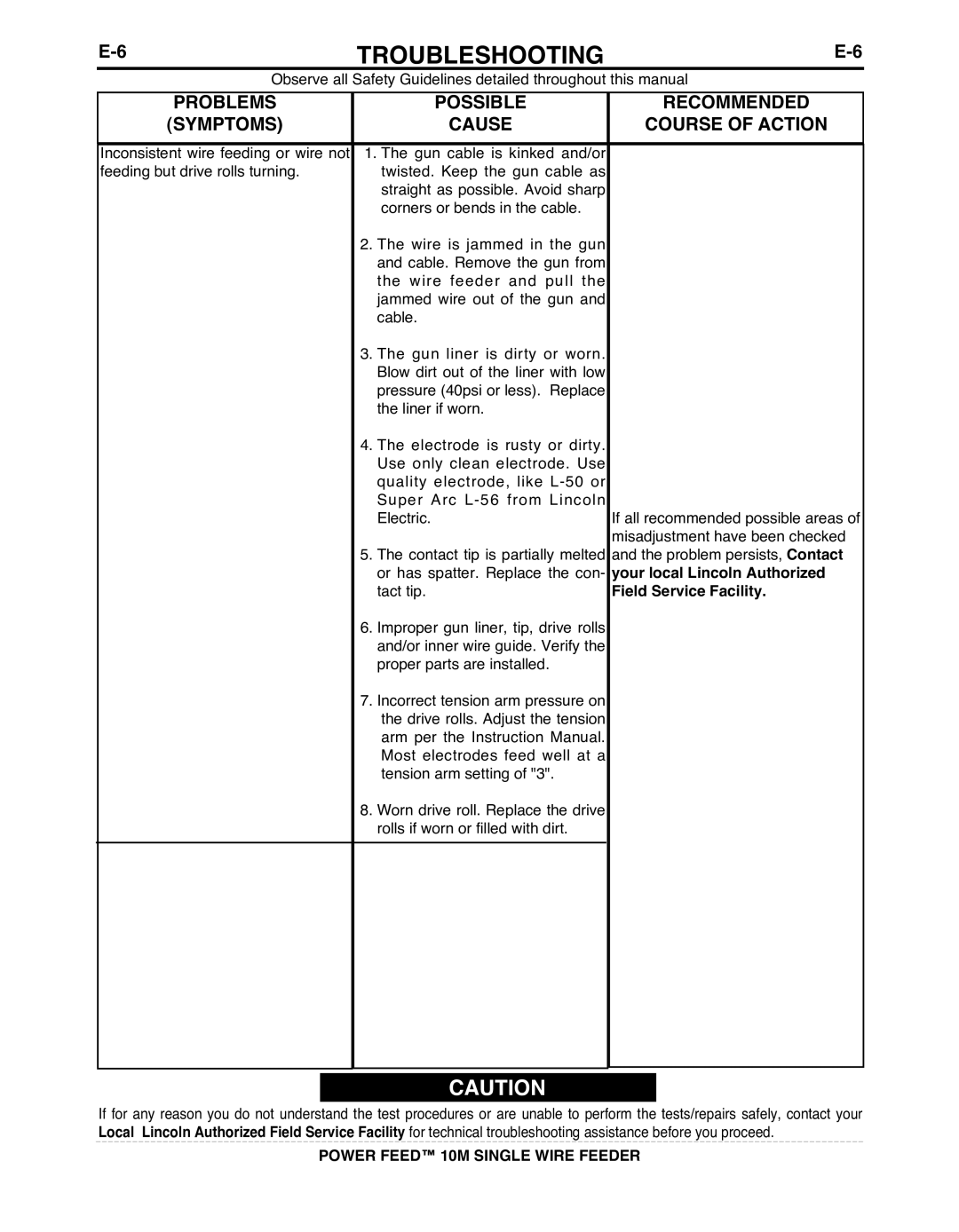

2. The wire is jammed in the gun and cable. Remove the gun from the wire feeder and pull the jammed wire out of the gun and cable.

3. The gun liner is dirty or worn. Blow dirt out of the liner with low pressure (40psi or less). Replace the liner if worn.

4. The electrode is rusty or dirty. Use only clean electrode. Use quality electrode, like L-50 or Super Arc L-56 from Lincoln

Electric.If all recommended possible areas of misadjustment have been checked

5. The contact tip is partially melted and the problem persists, Contact or has spatter. Replace the con- your local Lincoln Authorized

tact tip.Field Service Facility.

6. Improper gun liner, tip, drive rolls and/or inner wire guide. Verify the proper parts are installed.

7. Incorrect tension arm pressure on the drive rolls. Adjust the tension arm per the Instruction Manual. Most electrodes feed well at a tension arm setting of "3".

8. Worn drive roll. Replace the drive rolls if worn or filled with dirt.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER FEED™ 10M SINGLE WIRE FEEDER

1. The gun cable is kinked and/or twisted. Keep the gun cable as straight as possible. Avoid sharp corners or bends in the cable.

Inconsistent wire feeding or wire not feeding but drive rolls turning.

POSSIbLE

CAUSE

RECOMMENDED

COURSE OF ACTION

PRObLEMS

(SYMPTOMS)

|

| TROUbLESHOOTING | ||||||

|

|

|

|

|

|

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|