TOC

THEORY OF OPERATION

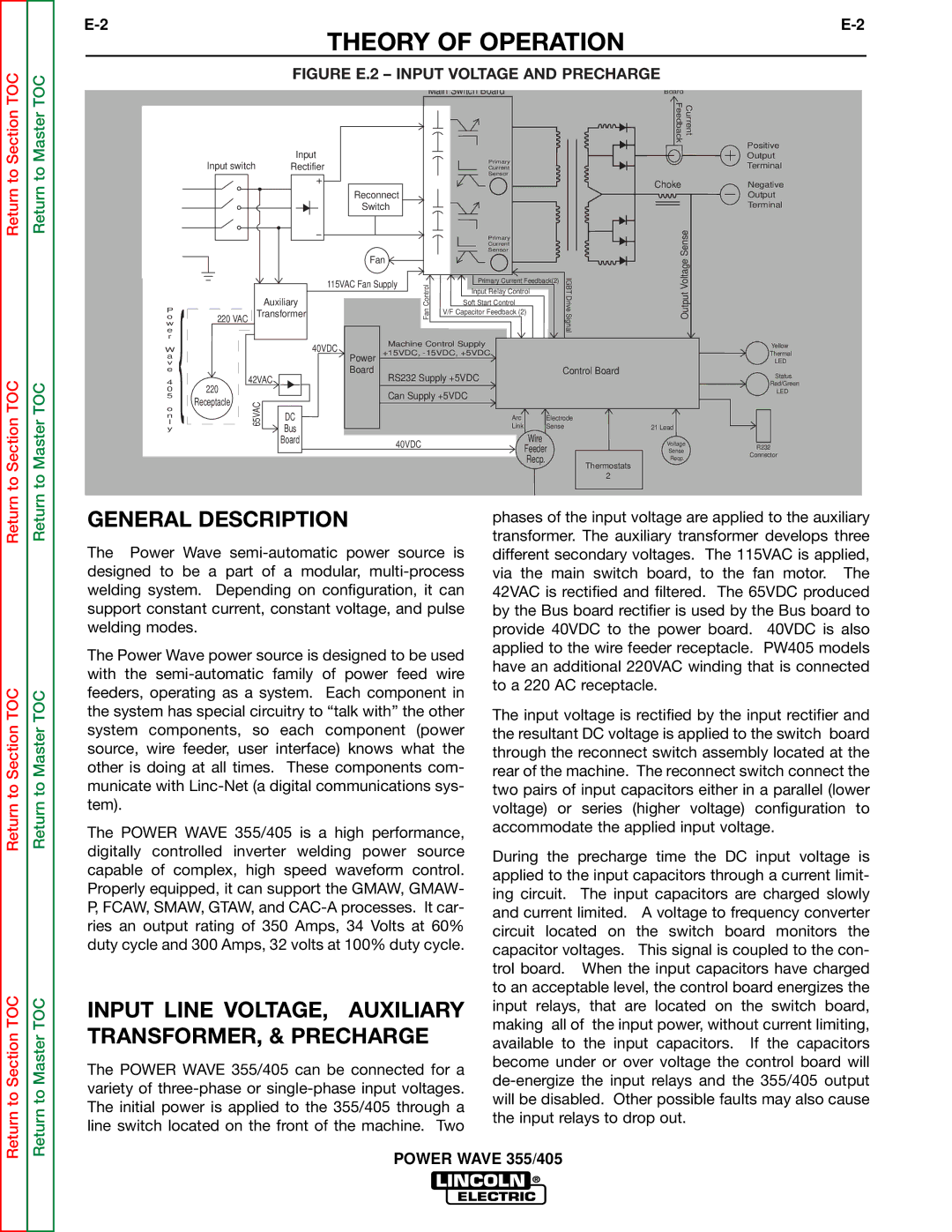

FIGURE E.2 – INPUT VOLTAGE AND PRECHARGE

P

o { w

e

r

W

a v e

4

0

5

o n l y

|

|

|

|

| Main Switch Board |

|

|

| |

Input switch |

| Input |

|

| Primary |

|

|

| |

| Rectifier |

|

|

|

|

| |||

|

|

| Current |

|

|

| |||

|

|

|

|

|

| Sensor |

|

|

|

|

|

| Reconnect |

|

|

|

|

| |

|

|

| Switch |

|

|

|

|

| |

|

|

|

|

|

| Primary |

|

|

|

|

|

|

|

|

| Current |

|

|

|

|

|

|

|

|

| Sensor |

|

|

|

|

|

| Fan |

|

|

|

|

| |

|

|

| 115VAC Fan Supply | CFanontrol | Primary Current Feedback(2) | IGBTDriveSignal | |||

|

|

| Input Relay Control |

| |||||

|

|

|

|

|

| ||||

|

|

| Auxiliary |

|

| Soft Start Control |

|

|

|

220 VAC |

| Transformer |

|

| V/F Capacitor Feedback (2) |

|

| ||

|

|

|

|

|

|

| |||

|

|

| 40VDC | Machine Control Supply |

|

|

| ||

|

|

| +15VDC, |

|

|

| |||

|

|

| Power |

|

|

| |||

|

|

| Board | RS232 Supply +5VDC |

|

| Control Board | ||

220 | 42VAC |

|

|

| |||||

|

|

| Can Supply +5VDC |

|

|

| |||

Receptacle | 65VAC |

|

|

|

| ||||

|

|

|

|

|

|

| |||

| DC |

|

| Arc |

| Electrode | |||

|

|

|

|

|

| ||||

|

|

| Bus |

|

| Link | Wire | Sense | |

|

|

| Board | 40VDC |

|

|

|

| |

|

|

|

|

|

| Feeder |

| ||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| Recp. |

| Thermostats |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| 2 |

Board | urrentC |

Feedback |

Choke

SenseVoltage

Output

21 Lead

Voltage

Sense

Recp.

Positive

Output

Terminal

Negative

Output

Terminal

Yellow

Thermal

LED

Status

Red/Green

LED

R232

Connector

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

GENERAL DESCRIPTION

The Power Wave

The Power Wave power source is designed to be used with the

The POWER WAVE 355/405 is a high performance, digitally controlled inverter welding power source capable of complex, high speed waveform control. Properly equipped, it can support the GMAW, GMAW- P, FCAW, SMAW, GTAW, and

INPUT LINE VOLTAGE, AUXILIARY TRANSFORMER, & PRECHARGE

The POWER WAVE 355/405 can be connected for a variety of

phases of the input voltage are applied to the auxiliary transformer. The auxiliary transformer develops three different secondary voltages. The 115VAC is applied, via the main switch board, to the fan motor. The 42VAC is rectified and filtered. The 65VDC produced by the Bus board rectifier is used by the Bus board to provide 40VDC to the power board. 40VDC is also applied to the wire feeder receptacle. PW405 models have an additional 220VAC winding that is connected to a 220 AC receptacle.

The input voltage is rectified by the input rectifier and the resultant DC voltage is applied to the switch board through the reconnect switch assembly located at the rear of the machine. The reconnect switch connect the two pairs of input capacitors either in a parallel (lower voltage) or series (higher voltage) configuration to accommodate the applied input voltage.

During the precharge time the DC input voltage is applied to the input capacitors through a current limit- ing circuit. The input capacitors are charged slowly and current limited. A voltage to frequency converter circuit located on the switch board monitors the capacitor voltages. This signal is coupled to the con- trol board. When the input capacitors have charged to an acceptable level, the control board energizes the input relays, that are located on the switch board, making all of the input power, without current limiting, available to the input capacitors. If the capacitors become under or over voltage the control board will