Section TOC

Master TOC

THEORY OF OPERATION

FIGURE E.4 – POWER BOARD, CONTROL BOARD

AND SERIAL PERIPHERAL INTERFACE (SPI) COMMUNICATIONS

Return to

Return to Master TOC

P

o { w

e

r

W

a

v

e

4

0

5

o n l y

Main Switch Board

Input

Input switch |

| Rectifier |

| Primary |

|

| |

|

| Current |

|

| |||

|

|

|

|

| Sensor |

|

|

|

|

| Reconnect |

|

|

| |

|

|

| Switch |

|

|

| |

|

|

|

|

| Primary |

|

|

|

|

|

|

| Current |

|

|

|

|

|

|

| Sensor |

|

|

|

|

| Fan |

|

| rive | |

|

|

|

|

|

|

| S |

|

|

| 115VAC Fan Supply | Primary Current Feedback(2) | IGBTDl | ||

|

|

| Soft Start Control |

| |||

|

|

| Auxiliary | Control |

| ||

|

|

|

|

| Input Relay Control |

|

|

220 VAC |

| Transformer | Fan | V/F Capacitor Feedback (2) |

| igna | |

|

|

|

| ||||

|

|

|

|

| |||

|

|

| 40VDC | Machine Control Supply |

|

| |

|

|

| +15VDC, |

|

| ||

|

|

| Power |

|

| ||

|

|

| Board | RS232 Supply +5VDC |

| Control Board | |

220 | 42VAC |

|

| ||||

|

|

| Can Supply +5VDC |

|

| ||

Receptacle | 65VAC |

|

|

| |||

|

|

|

|

| |||

| DC |

| Arc | Electrode | |||

|

|

| Bus |

| Link | Sense | |

|

|

| Board | 40VDC | Wire |

|

|

|

|

|

| Feeder |

| ||

|

|

|

|

|

| ||

|

|

|

|

| Recp. |

| Thermostats |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| 2 |

|

|

|

|

| To |

|

|

|

|

|

|

| Feeder |

| |

To Control

Board

Feedback | Current |

Choke

SenseVoltage

Output

21 Lead

Voltage

Sense

Recp.

Positive

Output

Terminal

Negative

Output

Terminal

Yellow

Thermal

LED

Status

Red/Green

LED

R232

Connector

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

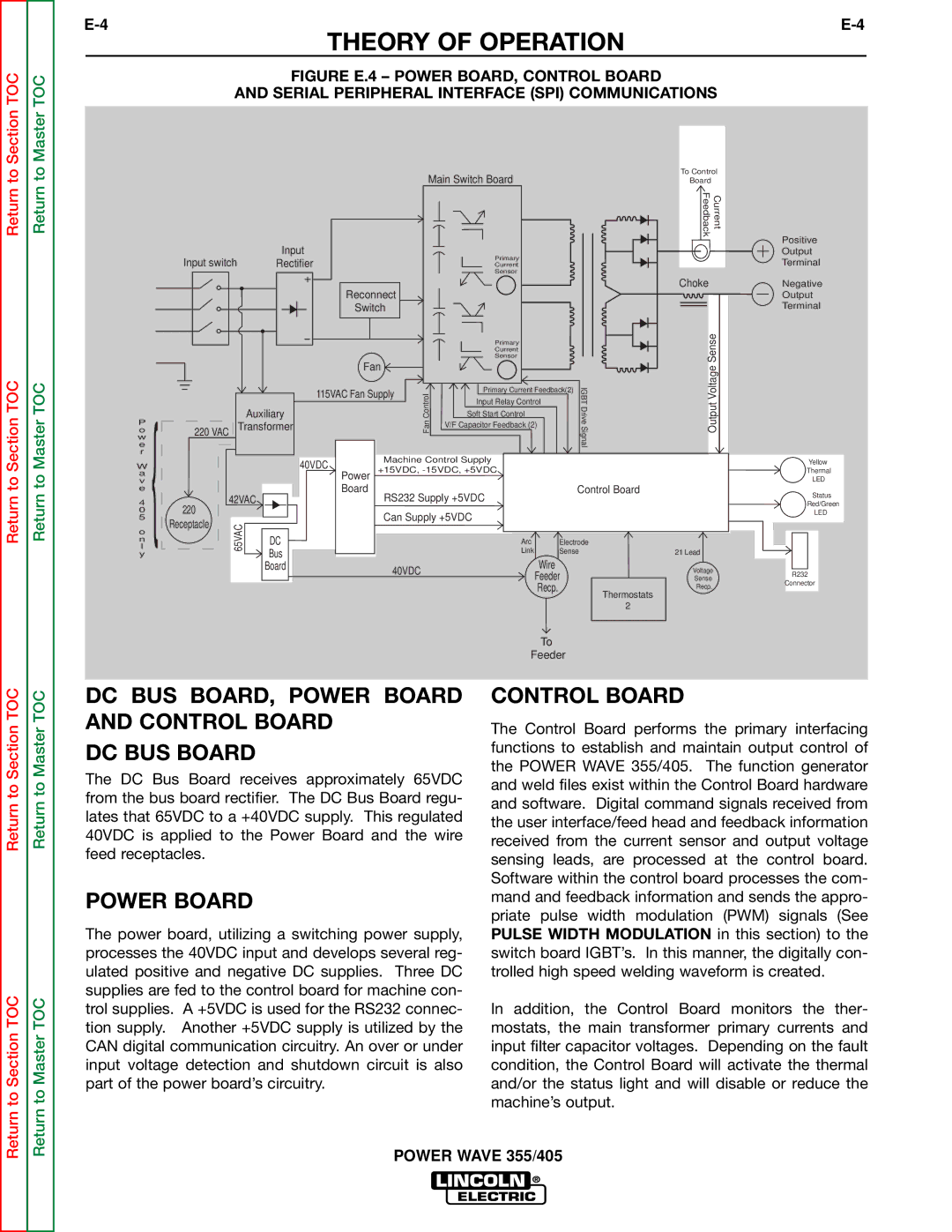

DC BUS BOARD, POWER BOARD AND CONTROL BOARD

DC BUS BOARD

The DC Bus Board receives approximately 65VDC from the bus board rectifier. The DC Bus Board regu- lates that 65VDC to a +40VDC supply. This regulated 40VDC is applied to the Power Board and the wire feed receptacles.

POWER BOARD

The power board, utilizing a switching power supply, processes the 40VDC input and develops several reg- ulated positive and negative DC supplies. Three DC supplies are fed to the control board for machine con- trol supplies. A +5VDC is used for the RS232 connec- tion supply. Another +5VDC supply is utilized by the CAN digital communication circuitry. An over or under input voltage detection and shutdown circuit is also part of the power board’s circuitry.

CONTROL BOARD

The Control Board performs the primary interfacing functions to establish and maintain output control of the POWER WAVE 355/405. The function generator and weld files exist within the Control Board hardware and software. Digital command signals received from the user interface/feed head and feedback information received from the current sensor and output voltage sensing leads, are processed at the control board. Software within the control board processes the com- mand and feedback information and sends the appro- priate pulse width modulation (PWM) signals (See PULSE WIDTH MODULATION in this section) to the switch board IGBT’s. In this manner, the digitally con- trolled high speed welding waveform is created.

In addition, the Control Board monitors the ther- mostats, the main transformer primary currents and input filter capacitor voltages. Depending on the fault condition, the Control Board will activate the thermal and/or the status light and will disable or reduce the machine’s output.