OPERATION

Return to Master TOC

Master TOC

TIG GTAW

The TIG mode features continuous control from 5 to 425 amps. The TIG mode can be run in either the Touch Start TIG or Scratch start mode.

The Arc Control level selects the starting mode.

Between

Between 0 and 10, the Scratch starting TIG mode is selected. In this range, the OCV of the machine is con- trolled between 50 and 70 volts.

Power Mode™ is a method of high speed regulation of the output power whenever an arc is established. It provides a fast response to changes in the arc. The higher the Power Mode Setting, the longer the arc. If a welding procedure is not established, the best way to determine the Power Mode Setting is by experimenta- tion until the desired output result is established.

In the Power Mode variables need to be set:

•Wire Feed Speed

•Output

•Arc Control

Setting up a Power Mode procedure is similar to set- ting a CV MIG procedure. Select a shielding gas appropriate for a short arc process.

•For steel, use 75/25 Ar/CO2 shield gas.

•For Stainless, select a Helium blend

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

SPECIAL WELDING PROCESSES AVAILABLE ON THIS MACHINE

POWER MODE™

The Power Mode™ process was developed by Lincoln to maintain a stable and smooth arc at low procedure settings which are needed to weld thin metal without

•Short Arc MIG at low procedure settings.

•Aluminum MIG welding.

• For Aluminum, use 100% Ar.

Start by setting the wire feed speed based upon mate- rial thickness and appropriate travel speed. Then adjust the Output knob as follows:

•For steel, listen for the traditional “frying egg” sound of a good

•For aluminum, simply adjust the Output knob until the desired arc length is obtained.

Note the Volts display is simply a relative number and DOES NOT correspond to voltage.

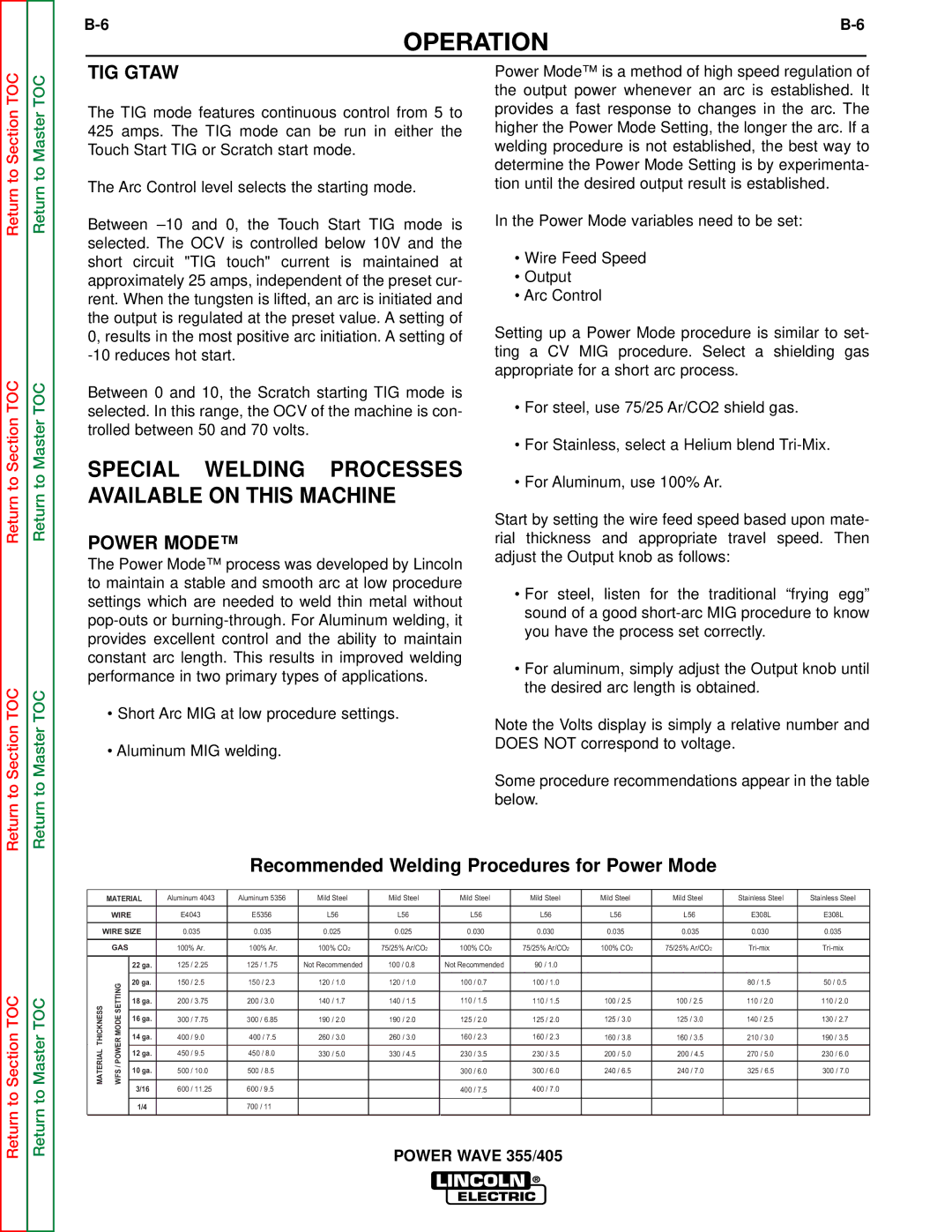

Some procedure recommendations appear in the table below.

Return to Section TOC

Return to Master TOC

Recommended Welding Procedures for Power Mode

| MATERIAL | Aluminum 4043 | Aluminum 5356 | Mild Steel | Mild Steel | Mild Steel | Mild Steel | Mild Steel | Mild Steel | Stainless Steel | Stainless Steel | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| WIRE |

| E4043 | E5356 | L56 | L56 | L56 | L56 | L56 | L56 | E308L | E308L | ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| WIRE SIZE | 0.035 | 0.035 | 0.025 | 0.025 | 0.030 | 0.030 | 0.035 | 0.035 | 0.030 | 0.035 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| GAS |

| 100% Ar. | 100% Ar. | 100% CO2 | 75/25% Ar/CO2 | 100% CO2 | 75/25% Ar/CO2 | 100% CO2 | 75/25% Ar/CO2 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 ga. | 125 | / 2.25 | 125 / 1.75 | Not Recommended | 100 / 0.8 | Not Recommended | 90 / 1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SETTINGMODEPOWER/WFS |

| 20 ga. | 150 | / 2.5 | 150 / 2.3 | 120 / 1.0 | 120 / 1.0 | 100 / 0.7 | 100 / 1.0 |

|

| 80 / 1.5 | 50 / 0.5 |

THICKNESSMATERIAL |

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 18 ga. | 200 | / 3.75 | 200 / 3.0 | 140 / 1.7 | 140 / 1.5 | 110 / 1.5 | 110 / 1.5 | 100 / 2.5 | 100 / 2.5 | 110 / 2.0 | 110 / 2.0 | ||

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 16 ga. | 300 | / 7.75 | 300 / 6.85 | 190 / 2.0 | 190 / 2.0 | 125 / 2.0 | 125 / 2.0 | 125 / 3.0 | 125 / 3.0 | 140 / 2.5 | 130 / 2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 14 ga. | 400 | / 9.0 | 400 / 7.5 | 260 / 3.0 | 260 / 3.0 | 160 / 2.3 | 160 / 2.3 | 160 / 3.8 | 160 / 3.5 | 210 / 3.0 | 190 / 3.5 |

|

|

| 12 ga. |

| / 9.5 |

|

|

|

|

|

|

|

|

|

|

|

| 450 | 450 / 8.0 | 330 / 5.0 | 330 / 4.5 | 230 / 3.5 | 230 / 3.5 | 200 / 5.0 | 200 / 4.5 | 270 / 5.0 | 230 / 6.0 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10 ga. | 500 | / 10.0 | 500 / 8.5 |

|

| 300 / 6.0 | 300 / 6.0 | 240 / 6.5 | 240 / 7.0 | 325 / 6.5 | 300 / 7.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3/16 | 600 | / 11.25 | 600 / 9.5 |

|

| 400 / 7.5 | 400 / 7.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/4 |

|

| 700 / 11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POWER WAVE 355/405