INSTALLATION

Return to Master TOC

Return to Master TOC

PULSE WELDING (GMAW-P)

The

Pulsed MIG is an advanced form of welding that takes the best of all the other forms of transfer while mini- mizing or eliminating their disadvantages. Unlike short circuit, pulsed MIG does not create spatter or run the risk of cold lapping. The welding positions in pulsed MIG are not limited as they are with globular or spray and its wire use is definitely more efficient. Unlike the spray arc process, pulsing offers controlled heat input that allows better welding on thin materials, lower wire feed speeds and leads to less distortion and improved overall quality and appearance. This is especially important with stainless, nickel and other alloys that are sensitive to heat input.

In

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

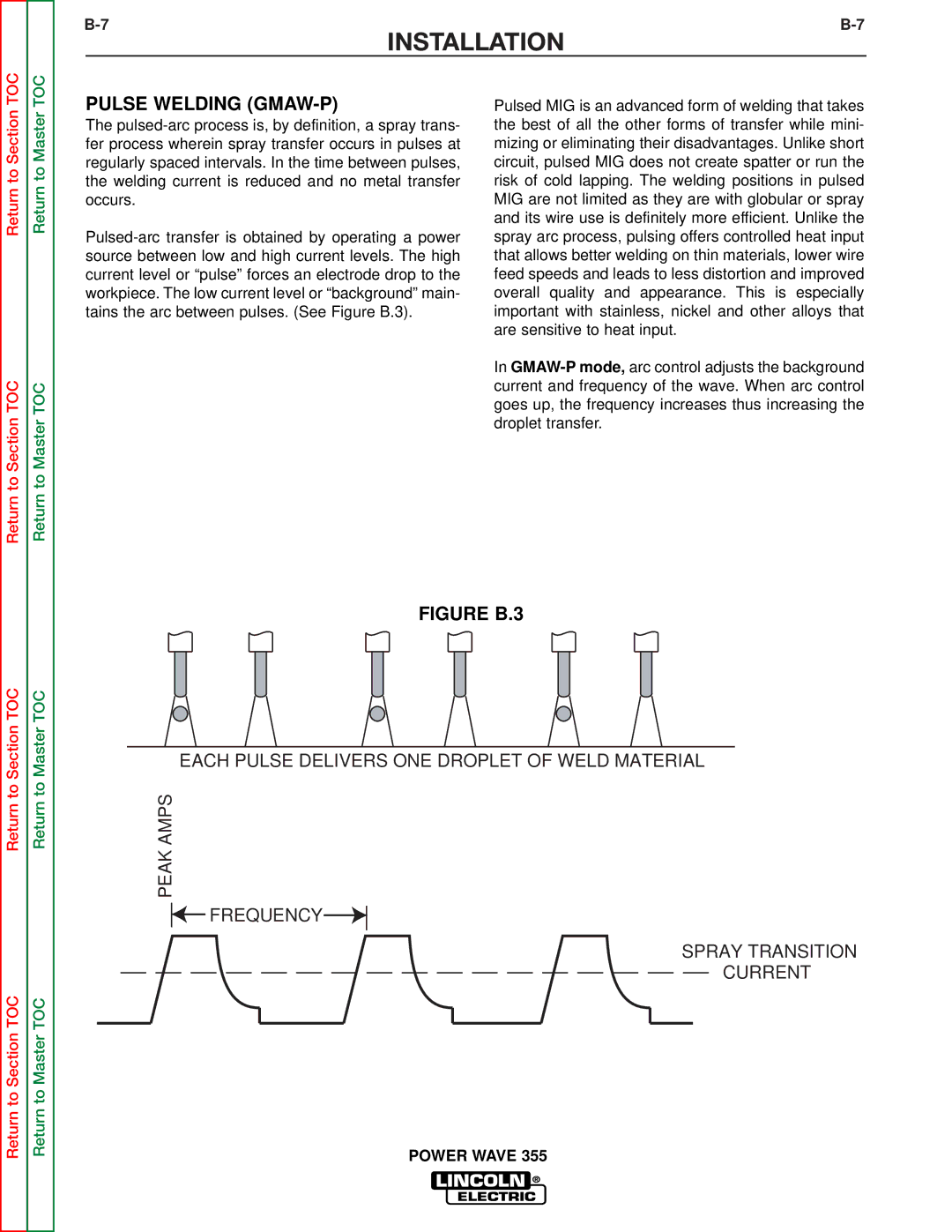

FIGURE B.3

EACH PULSE DELIVERS ONE DROPLET OF WELD MATERIAL

PEAK AMPS

FREQUENCY![]()

![]()

SPRAY TRANSITION

CURRENT

POWER WAVE 355