Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| TROUBLESHOOTING & REPAIR |

|

|

|

| |||||||||

|

|

|

|

|

|

|

| |||||||

| Observe Safety Guidelines |

|

|

|

|

|

| TROUBLESHOOTING GUIDE | ||||||

| detailed in the beginning of this manual. |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |||||||

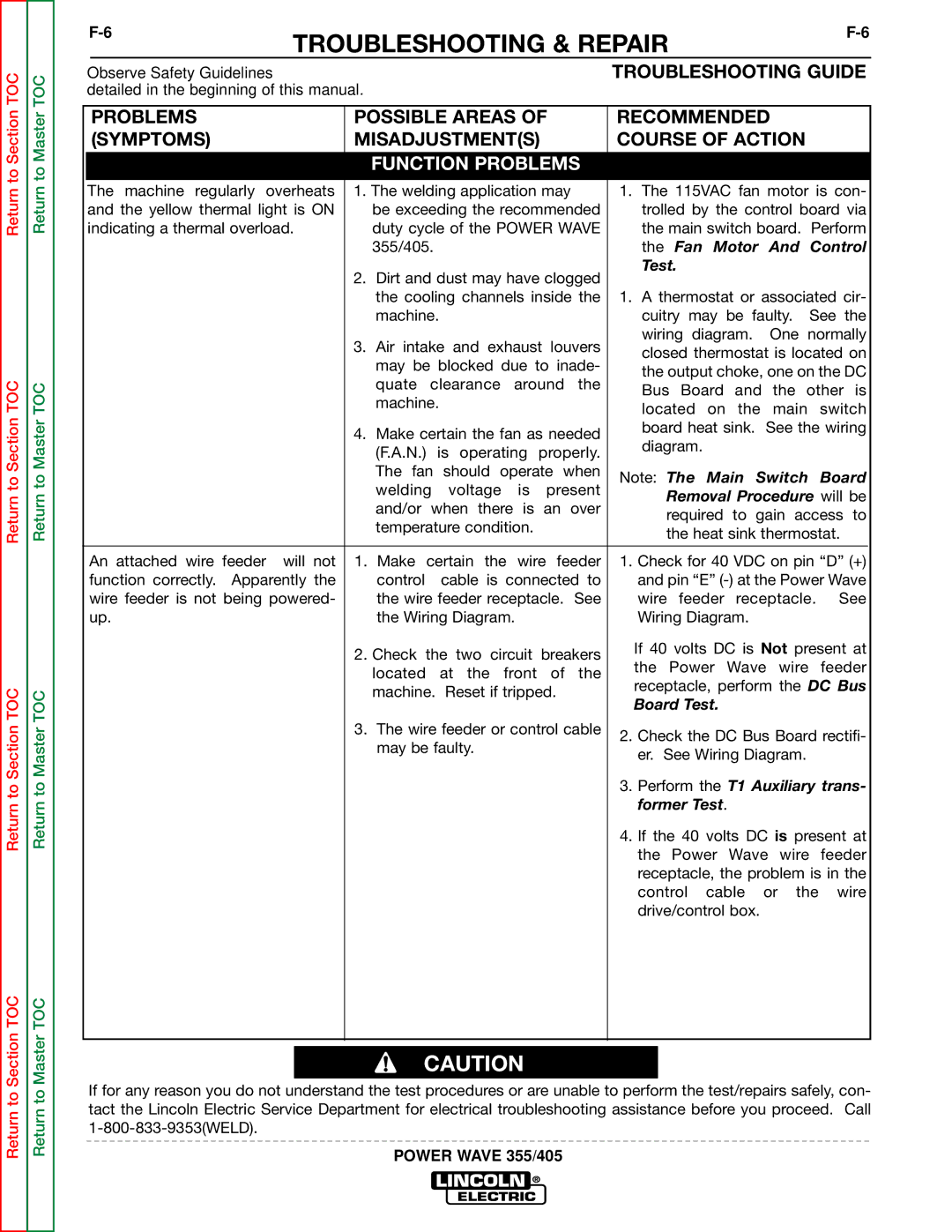

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

|

| |||||||

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| FUNCTION PROBLEMS |

|

|

|

|

|

|

| ||||

|

|

|

|

| ||||||||||

| The machine regularly overheats | 1. The welding application may | 1. The 115VAC fan motor is con- | |||||||||||

| and the yellow thermal light is ON | be exceeding the recommended | trolled by the control board via | |||||||||||

| indicating a thermal overload. | duty cycle of the POWER WAVE | the main switch board. Perform | |||||||||||

|

|

| 355/405. |

|

|

|

| the Fan Motor And Control | ||||||

|

|

| 2. Dirt and dust may have clogged | Test. |

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |||||

|

|

| the cooling channels inside the | 1. A thermostat or associated cir- | ||||||||||

|

|

| machine. |

|

|

| cuitry | may | be faulty. | See the | ||||

|

|

| 3. Air intake and exhaust louvers | wiring | diagram. | One | normally | |||||||

|

|

| closed thermostat is located on | |||||||||||

|

|

| may be blocked due to inade- | |||||||||||

|

|

| the output choke, one on the DC | |||||||||||

|

|

| quate clearance | around the | ||||||||||

|

|

| Bus Board | and | the | other is | ||||||||

|

|

| machine. |

|

|

| ||||||||

|

|

|

|

|

| located on the main switch | ||||||||

|

|

|

|

|

|

|

| |||||||

|

|

| 4. Make certain the fan as needed | board heat sink. See the wiring | ||||||||||

|

|

| diagram. |

|

|

|

|

| ||||||

|

|

| (F.A.N.) | is | operating | properly. |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||||

|

|

| The fan | should operate when | Note: The Main Switch | Board | ||||||||

|

|

| welding | voltage | is | present | ||||||||

|

|

| Removal Procedure will be | |||||||||||

|

|

| and/or when there is | an over | ||||||||||

|

|

| required | to gain access to | ||||||||||

|

|

| temperature condition. |

| ||||||||||

|

|

|

| the heat sink thermostat. | ||||||||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

| ||||||||||

| An attached wire feeder will not | 1. Make certain the wire feeder | 1. Check for 40 VDC on pin “D” (+) | |||||||||||

| function correctly. Apparently the | control | cable is connected to | and pin “E” | ||||||||||

| wire feeder is not being powered- | the wire feeder receptacle. See | wire feeder | receptacle. | See | |||||||||

| up. |

| the Wiring Diagram. |

| Wiring Diagram. |

|

|

|

| |||||

|

|

| 2. Check the | two circuit | breakers | If 40 volts DC is Not present at | ||||||||

|

|

| the Power | Wave | wire | feeder | ||||||||

|

|

| located | at | the | front | of the | |||||||

|

|

| receptacle, perform the DC Bus | |||||||||||

|

|

| machine. Reset if tripped. | |||||||||||

|

|

| Board Test. |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| 3. The wire feeder or control cable | 2. Check the DC Bus Board rectifi- | ||||||||||

|

|

| may be faulty. |

|

| |||||||||

|

|

|

|

| er. See Wiring Diagram. |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| 3. Perform the T1 Auxiliary trans- | ||||||

|

|

|

|

|

|

|

| former Test. |

|

|

|

| ||

|

|

|

|

|

|

|

| 4. If the 40 volts DC is present at | ||||||

|

|

|

|

|

|

|

| the Power Wave wire feeder | ||||||

|

|

|

|

|

|

|

| receptacle, the problem is in the | ||||||

|

|

|

|

|

|

|

| control cable or the wire | ||||||

|

|

|

|

|

|

|

| drive/control box. |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call