Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

EXTERNAL DIAGNOSTICS

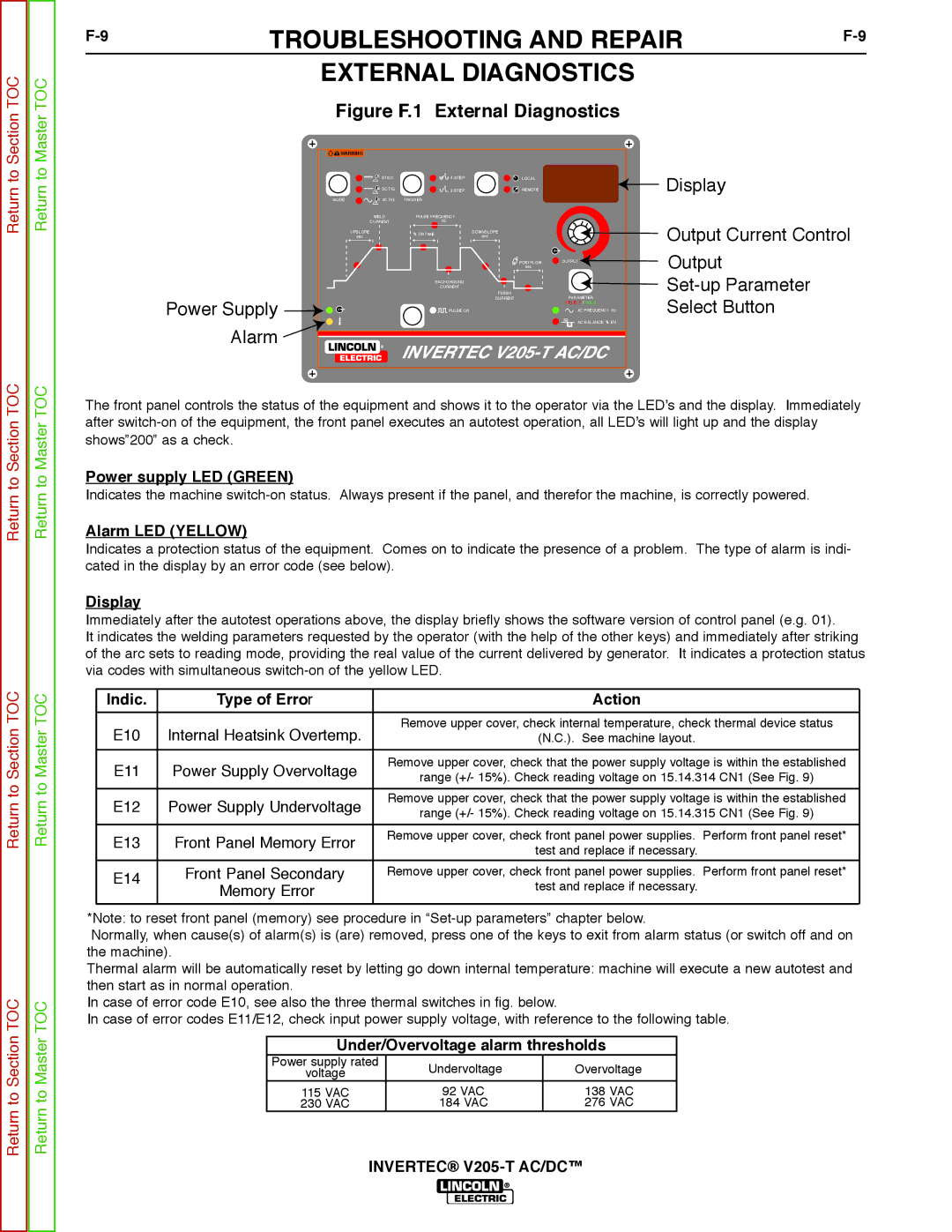

Figure F.1 External Diagnostics

| WARNING |

|

|

|

|

|

|

| STICK | LOCAL |

| Display | |

|

| DC TIG | REMOTE |

| ||

|

|

|

| |||

| MODE | AC TIG | TRIGGER |

|

|

|

|

| WELD | PULSE FREQUENCY |

|

|

|

|

| CURRENT | Hz |

|

|

|

| UPSLOPE |

| % ON TIME | DOWNSLOPE |

| Output Current Control |

| sec |

| sec |

| ||

|

|

|

|

|

| |

|

|

|

|

| A |

|

|

|

|

| POSTFLOW | OUTPUT | Output |

|

|

|

| sec |

| |

|

|

| BACKGROUND |

|

| |

|

|

| CURRENT |

|

| |

|

|

|

| FINISH |

| |

|

|

|

| CURRENT | PARAMETER | Select Button |

Power Supply |

|

|

|

| SELECT / HOLD | |

V |

| PULSE ON |

| AC FREQUENCY Hz | ||

|

|

|

|

| ||

|

|

|

|

| AC BALANCE % EN |

|

Alarm |

| ® |

|

|

|

|

The front panel controls the status of the equipment and shows it to the operator via the LED’s and the display. Immediately after

Power supply LED (GREEN)

Indicates the machine

Alarm LED (YELLOW)

Indicates a protection status of the equipment. Comes on to indicate the presence of a problem. The type of alarm is indi- cated in the display by an error code (see below).

Display

Immediately after the autotest operations above, the display briefly shows the software version of control panel (e.g. 01).

It indicates the welding parameters requested by the operator (with the help of the other keys) and immediately after striking of the arc sets to reading mode, providing the real value of the current delivered by generator. It indicates a protection status via codes with simultaneous

Indic. | Type of Error | Action | |

|

|

| |

E10 | Internal Heatsink Overtemp. | Remove upper cover, check internal temperature, check thermal device status | |

(N.C.). See machine layout. | |||

|

|

| |

E11 | Power Supply Overvoltage | Remove upper cover, check that the power supply voltage is within the established | |

range (+/- 15%). Check reading voltage on 15.14.314 CN1 (See Fig. 9) | |||

|

| ||

|

|

| |

E12 | Power Supply Undervoltage | Remove upper cover, check that the power supply voltage is within the established | |

range (+/- 15%). Check reading voltage on 15.14.315 CN1 (See Fig. 9) | |||

|

| ||

|

|

| |

E13 | Front Panel Memory Error | Remove upper cover, check front panel power supplies. Perform front panel reset* | |

test and replace if necessary. | |||

|

| ||

|

|

| |

E14 | Front Panel Secondary | Remove upper cover, check front panel power supplies. Perform front panel reset* | |

Memory Error | test and replace if necessary. | ||

| |||

|

| ||

|

|

|

*Note: to reset front panel (memory) see procedure in

Normally, when cause(s) of alarm(s) is (are) removed, press one of the keys to exit from alarm status (or switch off and on the machine).

Thermal alarm will be automatically reset by letting go down internal temperature: machine will execute a new autotest and then start as in normal operation.

In case of error code E10, see also the three thermal switches in fig. below.

In case of error codes E11/E12, check input power supply voltage, with reference to the following table.

Under/Overvoltage alarm thresholds

Power supply rated | Undervoltage | Overvoltage | |

voltage | |||

|

| ||

115 VAC | 92 VAC | 138 VAC | |

230 VAC | 184 VAC | 276 VAC |