THEORY OF OPERATION | ||

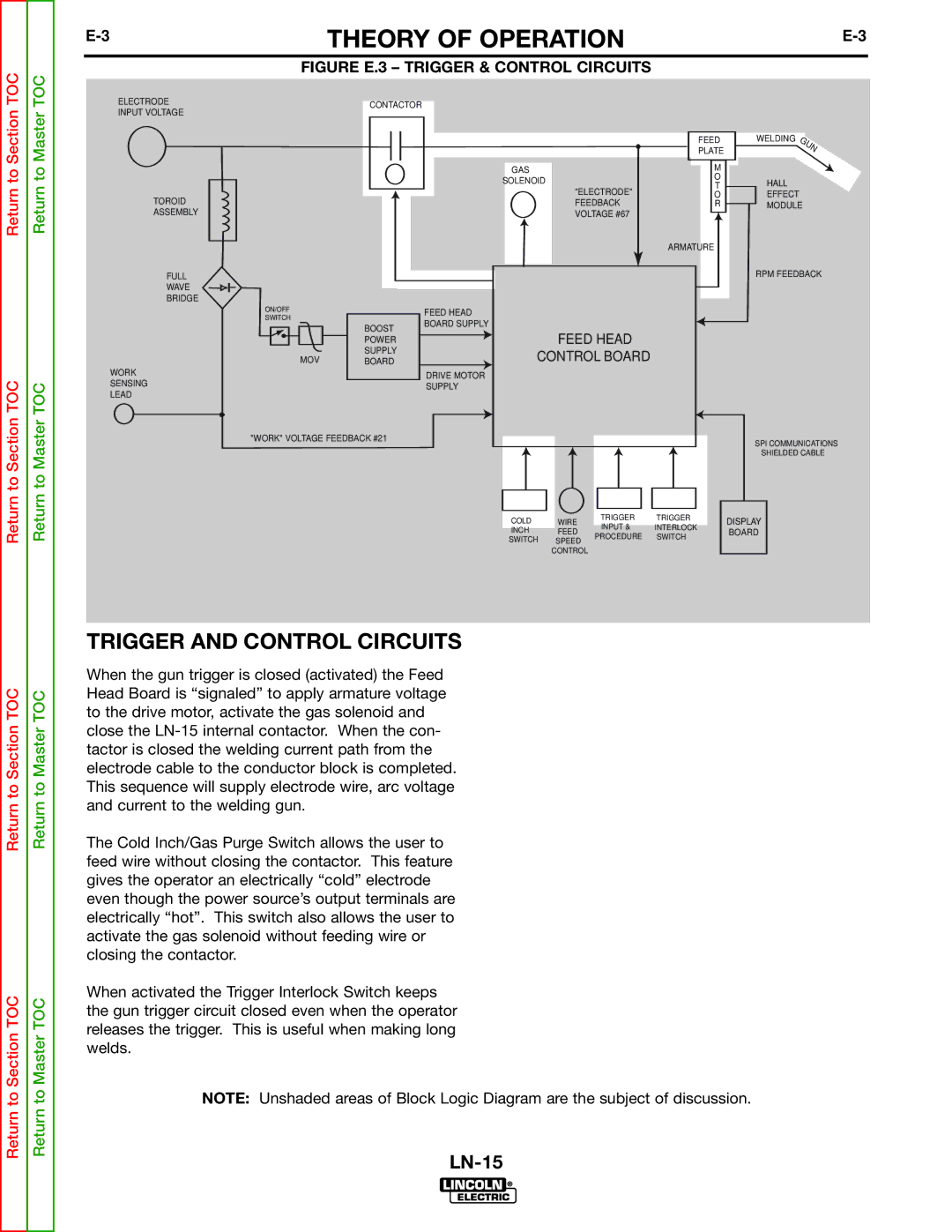

| FIGURE E.3 – TRIGGER & CONTROL CIRCUITS |

|

Return to Master TOC

ELECTRODE INPUT VOLTAGE

TOROID

ASSEMBLY

FULL

WAVE

BRIDGE

CONTACTOR

| FEED | WELDING |

| PLATE |

|

GAS |

|

|

M |

| |

SOLENOID | O | HALL |

T | ||

"ELECTRODE" | O | EFFECT |

FEEDBACK | R | MODULE |

VOLTAGE #67 |

|

|

ARMATURE

RPM FEEDBACK

TOC

ON/OFF

SWITCH

MOV

WORK SENSING LEAD

BOOST POWER SUPPLY BOARD

FEED HEAD BOARD SUPPLY

DRIVE MOTOR SUPPLY

FEED HEAD

CONTROL BOARD

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master

Return to Master TOC

Return to Master TOC

"WORK" VOLTAGE FEEDBACK #21

SPI COMMUNICATIONS

SHIELDED CABLE

COLD | WIRE | TRIGGER | TRIGGER | DISPLAY | |

INPUT & | INTERLOCK | ||||

INCH | FEED | BOARD | |||

PROCEDURE | SWITCH | ||||

SWITCH | SPEED |

| |||

|

|

| |||

| CONTROL |

|

|

|

TRIGGER AND CONTROL CIRCUITS

When the gun trigger is closed (activated) the Feed Head Board is “signaled” to apply armature voltage to the drive motor, activate the gas solenoid and close the

The Cold Inch/Gas Purge Switch allows the user to feed wire without closing the contactor. This feature gives the operator an electrically “cold” electrode even though the power source’s output terminals are electrically “hot”. This switch also allows the user to activate the gas solenoid without feeding wire or closing the contactor.

When activated the Trigger Interlock Switch keeps the gun trigger circuit closed even when the operator releases the trigger. This is useful when making long welds.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.