Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

|

CONTACTOR TEST

(continued)

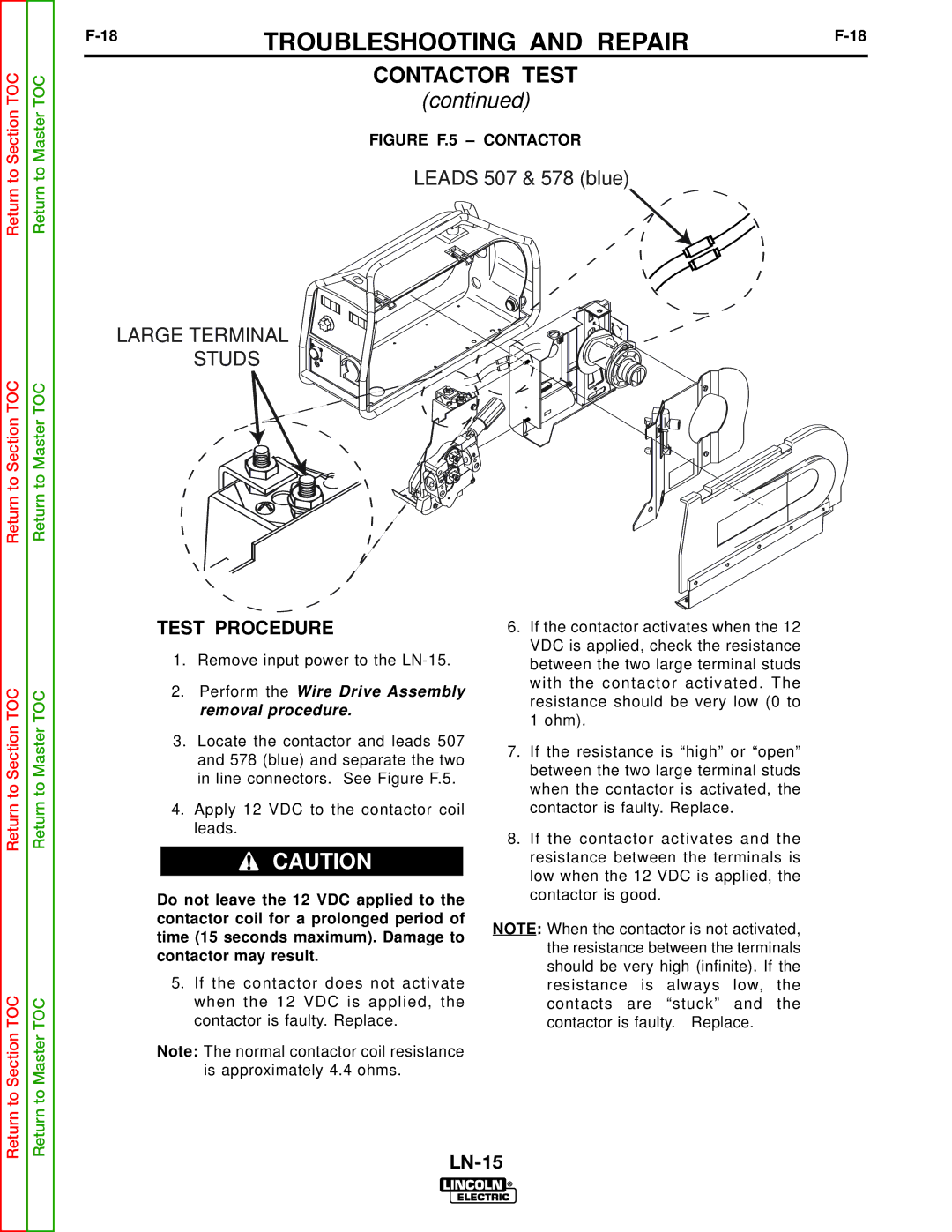

FIGURE F.5 – CONTACTOR

LEADS 507 & 578 (blue)

LARGE TERMINAL

STUDS

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TEST PROCEDURE

1.Remove input power to the

2.Perform the Wire Drive Assembly removal procedure.

3.Locate the contactor and leads 507 and 578 (blue) and separate the two in line connectors. See Figure F.5.

4.Apply 12 VDC to the contactor coil leads.

![]() CAUTION

CAUTION

Do not leave the 12 VDC applied to the contactor coil for a prolonged period of time (15 seconds maximum). Damage to contactor may result.

5.If the contactor does not activate when the 12 VDC is applied, the contactor is faulty. Replace.

Note: The normal contactor coil resistance is approximately 4.4 ohms.

6.If the contactor activates when the 12 VDC is applied, check the resistance between the two large terminal studs with the contactor activated. The resistance should be very low (0 to 1 ohm).

7.If the resistance is “high” or “open” between the two large terminal studs when the contactor is activated, the contactor is faulty. Replace.

8.If the contactor activates and the resistance between the terminals is low when the 12 VDC is applied, the contactor is good.

NOTE: When the contactor is not activated, the resistance between the terminals should be very high (infinite). If the resistance is always low, the contacts are “stuck” and the contactor is faulty. Replace.