Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

INSTALLATION |

| |||||

SAFETY PRECAUTIONS |

| The work clip lead attached to the front of the LN- | ||||

|

|

| 15 must be connected directly to the work using the | |||

WARNING |

| spring clip on the end of the lead. |

| |||

ELECTRIC SHOCK CAN KILL. |

| If the work clip lead is not connected, the | ||||

| operate. |

|

| |||

• ONLY QUALIFIED PERSONNEL |

|

| ||||

|

|

| ||||

SHOULD | PERFORM | THIS | The work clip lead also serves as a work sensing lead | |||

INSTALLATION. |

| |||||

| for the | |||||

• Turn off input power to the power | ||||||

user beyond the standard 15' (4.6m) length, the volt- | ||||||

source at the disconnect switch | ||||||

meter reading will be lower than the actual arc volts | ||||||

or fuse box before working on | ||||||

due to resistance in the extended lead. To minimize the | ||||||

this equipment. Turn off the input power to any | ||||||

error, the following lead size is recommended for the | ||||||

other equipment connected to the welding | ||||||

maximum extended lengths shown. |

| |||||

system at the disconnect switch or fuse box |

| |||||

|

|

| ||||

before working on the equipment. |

| AWG | Max. Length | |||

• Do not touch electrically hot parts. |

| |||||

| #14 | 25 ft | (7.6m) | |||

• Do not touch metal portions of the | ||||||

#12 | 50 ft | (15.2m) | ||||

lead clip when the welding power source is. | ||||||

#10 | 100 ft | (30.5m) | ||||

• Do not connect the | ||||||

#6 | 200 ft | (61.0m) | ||||

power source, a SQUARE WAVE TIG power | ||||||

|

|

| ||||

source, or a PLASMA CUTTING power source. |

|

|

| |||

|

|

| ||||

LOCATION |

|

|

|

|

| |

The |

|

|

| |||

horizontal surface. Do not submerge the |

|

|

| |||

water. The best practice is to keep the wire feeder in |

|

|

| |||

a dry environment. When working outdoors in severe |

|

|

| |||

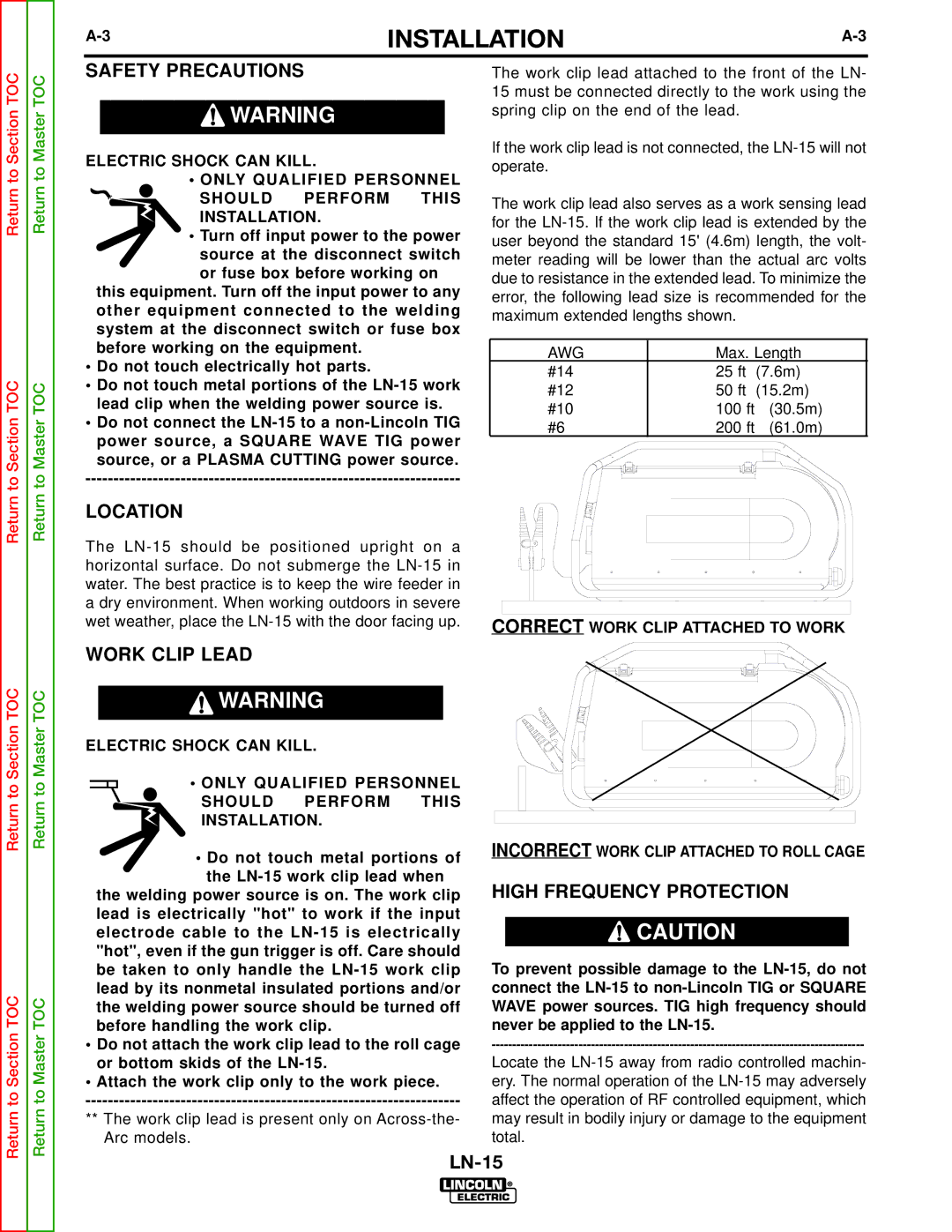

wet weather, place the | CORRECT WORK CLIP ATTACHED TO WORK | |||||

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

WORK CLIP LEAD

![]() WARNING

WARNING

ELECTRIC SHOCK CAN KILL.

• ONLY QUALIFIED PERSONNEL SHOULD PERFORM THIS INSTALLATION.

•Do not touch metal portions of the

the welding power source is on. The work clip lead is electrically "hot" to work if the input electrode cable to the

•Do not attach the work clip lead to the roll cage or bottom skids of the

•Attach the work clip only to the work piece.

** The work clip lead is present only on

INCORRECT WORK CLIP ATTACHED TO ROLL CAGE

HIGH FREQUENCY PROTECTION

![]() CAUTION

CAUTION

To prevent possible damage to the

Locate the