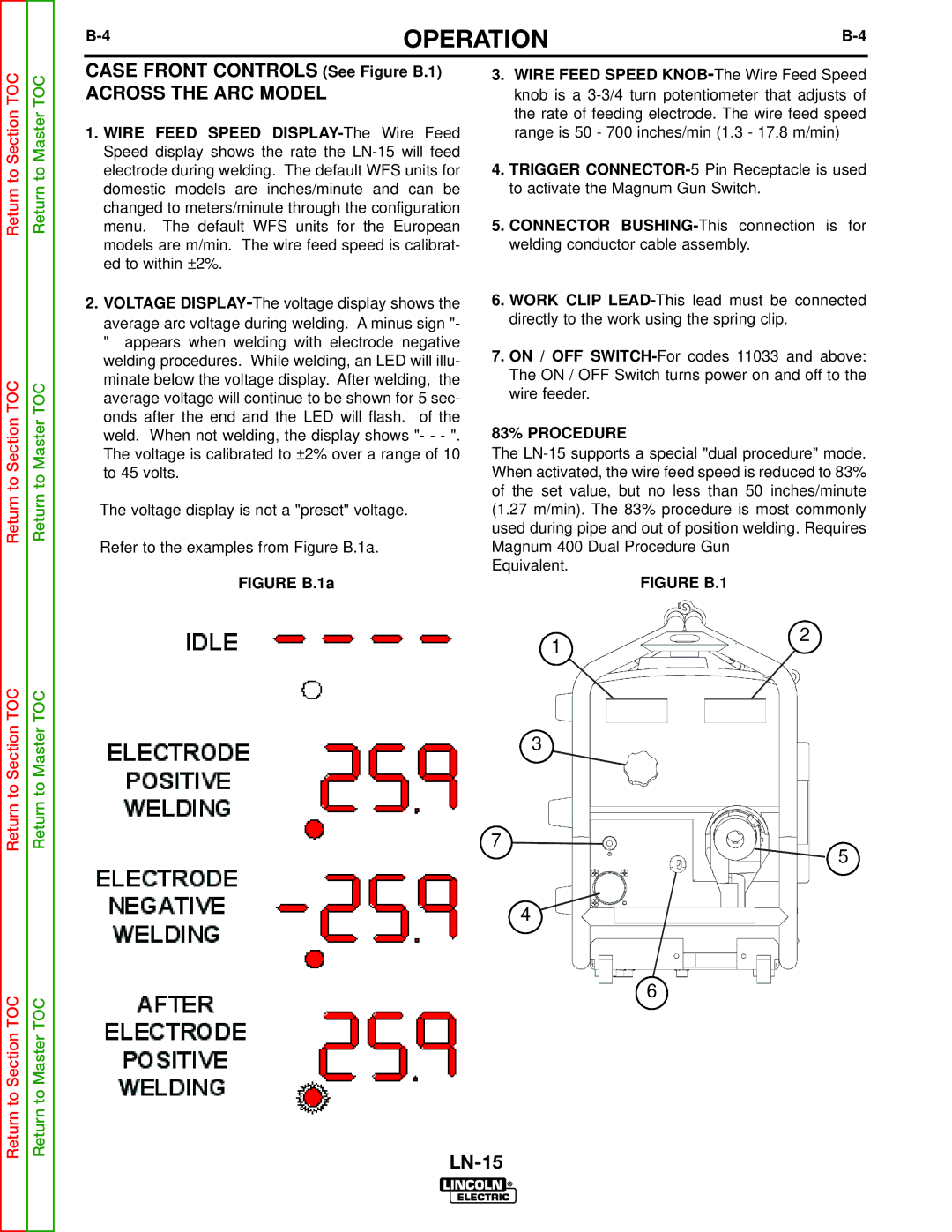

CASE FRONT CONTROLS (See Figure B.1)

ACROSS THE ARC MODEL

1.WIRE FEED SPEED DISPLAY-The Wire Feed Speed display shows the rate the LN-15 will feed electrode during welding. The default WFS units for domestic models are inches/minute and can be changed to meters/minute through the configuration menu. The default WFS units for the European models are m/min. The wire feed speed is calibrat- ed to within ±2%.

2.VOLTAGE DISPLAY-The voltage display shows the average arc voltage during welding. A minus sign "- " appears when welding with electrode negative welding procedures. While welding, an LED will illu- minate below the voltage display. After welding, the average voltage will continue to be shown for 5 sec- onds after the end and the LED will flash. of the weld. When not welding, the display shows "- - - ". The voltage is calibrated to ±2% over a range of 10 to 45 volts.

The voltage display is not a "preset" voltage.

Refer to the examples from Figure B.1a.

FIGURE B.1a

3.WIRE FEED SPEED KNOB-The Wire Feed Speed knob is a 3-3/4 turn potentiometer that adjusts of the rate of feeding electrode. The wire feed speed range is 50 - 700 inches/min (1.3 - 17.8 m/min)

4.TRIGGER CONNECTOR-5 Pin Receptacle is used to activate the Magnum Gun Switch.

5.CONNECTOR BUSHING-This connection is for welding conductor cable assembly.

6.WORK CLIP LEAD-This lead must be connected directly to the work using the spring clip.

7.ON / OFF SWITCH-For codes 11033 and above: The ON / OFF Switch turns power on and off to the wire feeder.

83% PROCEDURE

The LN-15 supports a special "dual procedure" mode. When activated, the wire feed speed is reduced to 83% of the set value, but no less than 50 inches/minute (1.27 m/min). The 83% procedure is most commonly used during pipe and out of position welding. Requires Magnum 400 Dual Procedure Gun

Equivalent.

FIGURE B.1