TOC

TOC

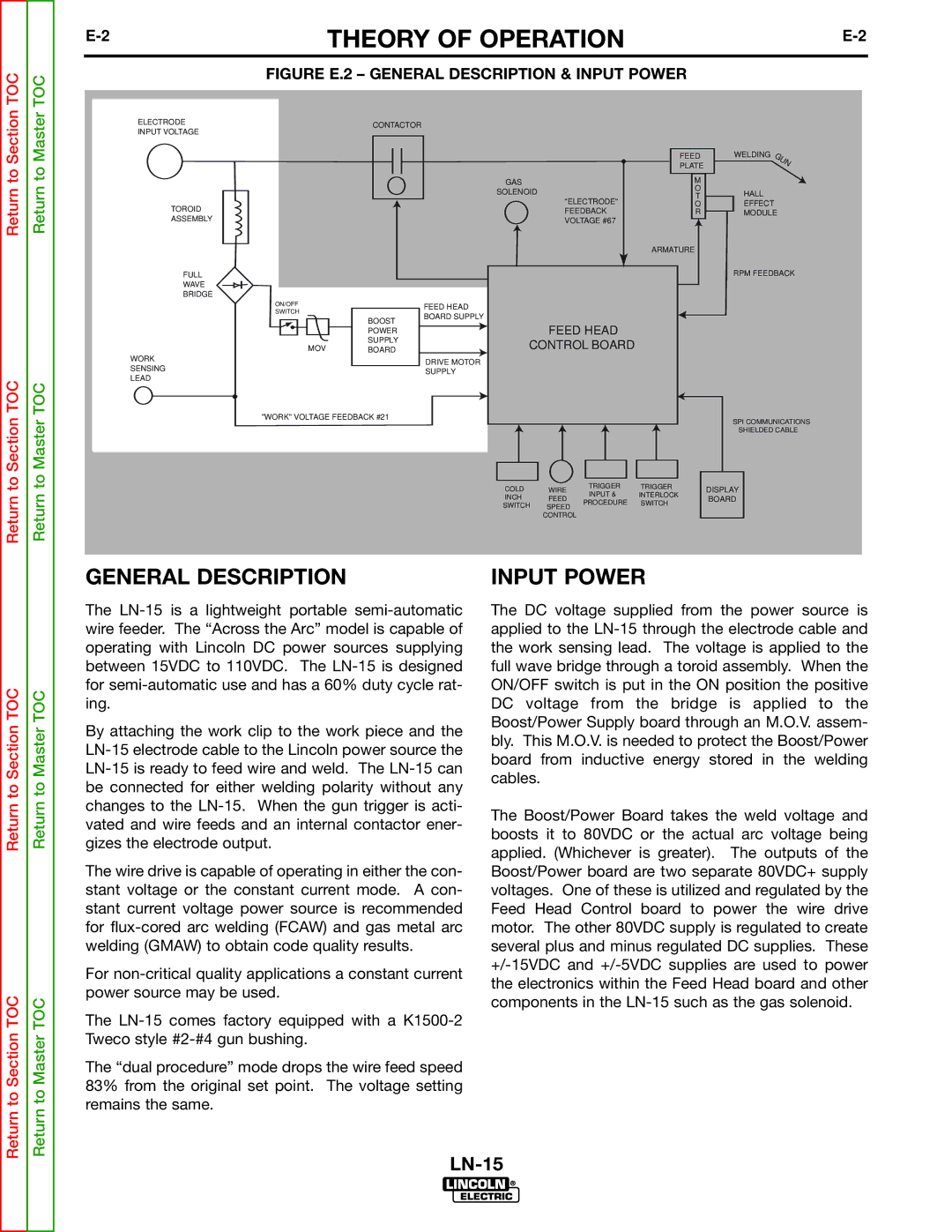

THEORY OF OPERATION | ||

| FIGURE E.2 – GENERAL DESCRIPTION & INPUT POWER |

|

ELECTRODE INPUT VOLTAGE

TOROID

ASSEMBLY

FULL

WAVE

BRIDGE

CONTACTOR

| FEED | WELDING | |

| PLATE |

| |

GAS | M |

| |

SOLENOID | O | HALL | |

T | |||

"ELECTRODE" | EFFECT | ||

O | |||

FEEDBACK | R | MODULE | |

VOLTAGE #67 |

|

|

ARMATURE

RPM FEEDBACK

ON/OFF

SWITCH

MOV

WORK SENSING LEAD

BOOST POWER SUPPLY BOARD

FEED HEAD BOARD SUPPLY

DRIVE MOTOR SUPPLY

FEED HEAD

CONTROL BOARD

Return to Master TOC

"WORK" VOLTAGE FEEDBACK #21

SPI COMMUNICATIONS

SHIELDED CABLE

COLD | WIRE | TRIGGER | TRIGGER | DISPLAY | |

INPUT & | INTERLOCK | ||||

INCH | FEED | BOARD | |||

PROCEDURE | SWITCH | ||||

SWITCH | SPEED |

| |||

|

|

| |||

| CONTROL |

|

|

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

GENERAL DESCRIPTION

The

By attaching the work clip to the work piece and the

The wire drive is capable of operating in either the con- stant voltage or the constant current mode. A con- stant current voltage power source is recommended for

For

The

The “dual procedure” mode drops the wire feed speed 83% from the original set point. The voltage setting remains the same.

INPUT POWER

The DC voltage supplied from the power source is applied to the

The Boost/Power Board takes the weld voltage and boosts it to 80VDC or the actual arc voltage being applied. (Whichever is greater). The outputs of the Boost/Power board are two separate 80VDC+ supply voltages. One of these is utilized and regulated by the Feed Head Control board to power the wire drive motor. The other 80VDC supply is regulated to create several plus and minus regulated DC supplies. These