Return to Section TOC

Return to Master TOC

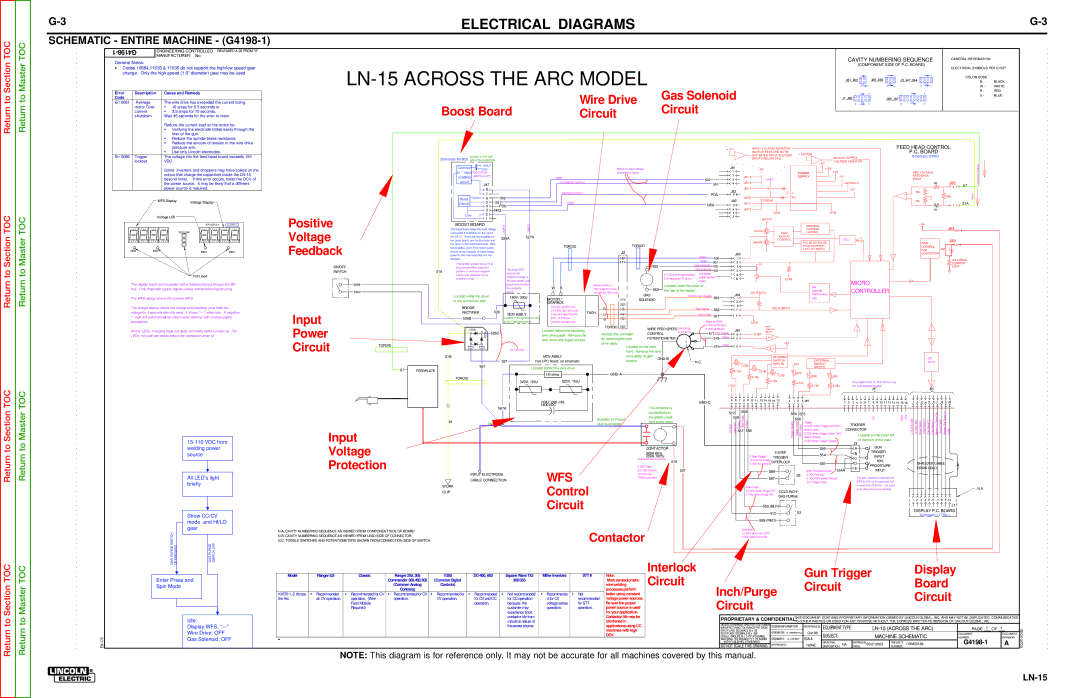

SCHEMATIC - ENTIRE MACHINE - (G4198-1)

| ENGINEERING CONTROLLED RELEASED A.03 FROM "X" | |

MANUFACTURER: | No | |

General Notes:

ξCodes 10864,11033 & 11035 do not support the high/low speed gear change. Only the high speed (1.8" diameter) gear may be used.

Error | Description | Cause and Remedy |

Code |

|

|

Err 0081 | Average | The wire drive has exceeded the current rating: |

| motor Over- | 10 amps for 0.5 seconds or |

| current | 3.5 amps for 10 seconds. |

| shutdown | Wait 45 seconds for the error to reset. |

|

| Reduce the current load on the motor by: |

|

| Verifying the electrode slides easily through the |

|

| liner of the gun. |

|

| Reduce the spindle brake resistance. |

|

| Reduce the amount of tension in the wire drive |

ELECTRICAL DIAGRAMS |

|

|

|

|

|

|

|

| ||

|

|

| CAVITY NUMBERING SEQUENCE | GENERAL INFORMATION |

| |||||

|

|

| (COMPONENT SIDE OF P.C. BOARD) |

| ELECTRICAL SYMBOLS PER E1537 | |||||

|

|

|

|

|

|

|

| |||

| 3 | 4 | 4 | 6 | 5 | 8 | W - | WHITE | ||

|

|

| 1 | 2 | 1 | 3 | 1 | 4 | COLOR CODE |

|

|

|

| J81,J82 | J83,J88 |

| J2,J47,J84 |

|

| B - | BLACK |

|

|

|

|

|

|

|

|

| ||

|

| Gas Solenoid | J1,J86 |

| J85,J87 |

|

| R - | RED | |

| Wire Drive |

| 1 | 5 |

| 1 | 8 |

| U - | BLUE |

|

|

|

|

|

|

|

| |||

Boost Board | Circuit | 6 | 10 |

| 9 | 16 |

|

|

| |

Circuit |

|

|

|

|

|

|

|

| ||

| pressure arm. |

| Use only Lincoln electrodes. |

Err 0086 Trigger | The voltage into the feed head board exceeds 150 |

lockout | VDC. |

Located on the right

Schematic M19752 side of the control box.

- INPUT |

+ Vin

INPUT VOLTAGE MONITOR

(MOTOR FETS ARE BOTH

OFF WHEN INPUT VOLTAGE + MOTOR DROPS BELOW 20V)

+5V

MOTOR SUPPLY VOLTAGE MONITOR

FEED HEAD CONTROL

P.C. BOARD

Schematic G3883

Some inverters and choppers may have spikes on the |

output that charge the capacitors inside the |

beyond limits. If this error occurs, lower the OCV of |

the power source. It may be likely that a different |

power source is required. |

WFS Display | Voltage Display |

| |

Voltage LED |

|

Positive

Common |

| COM |

|

to | ISOLATION |

| |

enabling | SWITCH (FET) |

| |

circuit |

| J47 |

|

|

|

| |

|

| 8 |

|

|

| 7 |

|

Boost | COM | 6 | 502 |

Circuit |

| 5 | 501 |

|

| 4 | POS |

|

| 3 | NEG |

COM |

| 2 |

|

|

| 1 |

|

80VDC or weld voltage, whichever is higher

COM

FEEDHEAD SUPPLY

MOTOR SUPPLY

COM

J81

1

2

5023

5014

J83

POS 6

J82

NEG3

4

1

2

| +Vin |

|

|

| POWER |

+ motor | SUPPLY | |

|

| |

|

| |

|

| |

|

| + |

1200uF | Vin | |

| - | |

| ||

|

| |

|

| |

| COM |

|

| + MOTOR |

|

+15V

+5V(TACH)

+5V

COM

ARC VOLTAGE

FEEDBACK

IN PUT

1M | J88 | 67 |

| 4 |

78k

+ | 40k |

|

- |

| |

|

| |

| 78k | 21A |

| 1 | |

|

| |

| 1M |

|

Work

Electrode Voltage

|

| SPI DISPLAY | |

|

| YELLOW |

|

RED | RED | RED | RED |

|

| ||

|

| Not Used |

|

The display board communicates to the feedhead board through the SPI bus. Only thepower supply signals can be monitored during servicing.

The WFS always shows the present WFS.

The voltage display shows the voltage while welding, plus holds the voltage for 5 seconds after the weld. It shows

All the LEDs, including those not used, will briefly light on power up. The LED's not used are visible behind the nameplate when lit.

Voltage Feedback

ON/OFF

SWITCH

526B

526C

Input

Power

Circuit

TOROID

67

BOOST BOARD

| The boost board takes the weld voltage |

| and boosts it to 80VDC for the rest of |

| the |

| the boost board, one for the motor and |

| the other for the feedhead board. With |

| two supplies, even if the motor supply |

| should droop because of heavy loads, |

| power to the feed head board is not |

| affected. |

| The rectifier allows the |

| be powered either electrode |

21A | positive or electrode negative |

| without any switches for the |

| customer to set. |

Located under the cover |

|

in the control box ably. |

|

BRIDGE |

|

RECTIFIER | 526 |

526B |

|

+ | 526C |

| |

- |

|

21B |

|

567 |

|

FEEDPLATE |

|

TOROID |

|

+INPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| AVERAGE |

|

| |

|

|

|

|

|

|

|

|

|

|

| DRIVE |

|

|

| CURRENT |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| PWM |

| LIMITING |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

526A | 527A |

|

|

|

|

|

|

|

|

|

|

|

|

| MOTOR |

|

|

| CPLD |

|

|

|

|

|

|

|

|

|

|

|

|

|

| CONTROL |

|

|

| ||

|

|

|

|

| TOROID |

|

|

|

|

|

| BRAKE |

|

|

| PULSE BY PULSE |

|

| |

|

| TOROID |

|

|

|

|

|

|

|

|

|

|

|

| PEAK CURRENT |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LIMIT (27 AMPS) |

|

|

|

|

|

|

| J2 |

|

|

|

|

|

| J83 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Motor + |

|

|

|

|

|

|

|

|

| |

|

|

|

|

| 8 |

|

|

| 550 |

| 1 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| Motor - |

|

|

|

|

|

|

|

| |||

|

|

|

|

| 7 |

|

|

| 551 |

| 2 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| +15V |

|

|

|

|

|

| |||

|

|

|

|

|

| 552 |

| Gas Solenoid + 552 |

| 3 |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

This large MOV |

|

|

|

|

|

|

|

| Gas Solenoid - 553 |

| 4 |

|

|

|

|

|

|

| |

absorbs the |

|

|

|

|

|

| 6.5 VDC when gas flowing | see power |

|

| 5 |

|

|

|

|

|

|

| |

inductive energy in |

|

|

|

|

| supply section |

|

|

|

|

|

|

|

| |||||

|

|

|

|

| Coil measures 21 ohms |

| 6 |

|

| COM |

|

|

|

| |||||

the weld cables and |

|

|

|

|

| molex |

|

|

|

|

|

|

| MICRO | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

power source when | W B | Measure B to U |

|

| Located under the cover at |

|

|

|

|

|

|

| gas |

| |||||

the contactor |

| 120 Hz @ 50 in/min |

| 553 |

|

|

|

|

|

|

|

| CONTROLLER | ||||||

|

| the rear of the feeder |

|

|

|

|

|

|

|

| solenoid |

| |||||||

opens. |

|

| 1.6 kHz @ 700 in/min |

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| +5V (TACH) |

|

|

| ||||||||

150V, 300J |

|

|

|

| GAS |

| 15 VDC Tach Supply | 563 |

| J84 |

|

|

|

| PWM control |

|

| ||

MOTOR / |

|

| 1 | SOLENOID |

|

|

|

| 1 |

|

|

|

| ckts |

|

| |||

|

| GEARBOX |

|

| 2 |

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

| 2.6 VDC @ 50 in/min |

|

|

|

|

| Tach Signal |

|

| 3 |

|

| TACH INPUT |

|

|

|

| |

|

|

| R | 3 |

|

|

| 562 |

|

|

|

|

|

|

|

| |||

|

| 27.4 VDC @ 700 in/min |

|

|

|

|

| 7 |

|

|

|

|

|

| |||||

|

| TACH. |

|

|

|

|

|

|

|

|

|

|

| ||||||

MOV ASBLY | 8 sec average Current | U | 4 |

|

|

| Tach COM | 561 |

| 4 |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

limit = 3.5 Amps |

|

|

|

|

|

|

|

|

|

|

|

| |||||||

Located in the control box next |

| B | 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

to the Feedhead board. | (Limit is software set) |

|

|

|

| Wiper to COM |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| COM |

|

|

|

|

|

| |||||

|

|

|

| TOROID | 6 | WIRE FEED SPEED 10K Ohms | 5 VDC at 700 ipm |

|

| WFS |

|

|

|

| |||||

|

| Located behind the insulating |

|

| 0 VDC at 50 ipm | J84 |

| ANALOG |

|

|

|

| |||||||

|

|

| Access this connector | CONTROL |

| 577 POT Supply |

| INPUT |

|

|

|

| |||||||

|

| wire drive panel. Remove the |

|

| 8 | COM |

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

| by removing the wire | POTENTIOMETER | 1 |

| 576 | Wiper | 6 |

|

| A=1 |

|

|

|

| |||

|

| wire drive ably ot gain access. |

|

|

|

|

|

|

|

| |||||||||

|

|

| drive asbly. |

|

|

| 2 |

|

|

|

|

|

| +5V |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

| Located on the case |

| 3 |

| 575 | COM |

|

|

|

|

|

|

| |||

15- 110 VDC |

|

|

|

|

|

| 5 |

|

| A=1 |

|

|

|

| |||||

|

|

|

| front. Remove the wire |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| MOV ASBLY |

|

| drive asbly to gain |

|

|

|

|

|

|

|

| INTERNAL |

|

|

|

| |

527 | Not a PC board; no schematic. |

|

| access. |

| N.C. |

|

| 2k |

|

| SWITCH |

| EXTERNAL |

|

| |||

|

|

|

|

|

|

|

|

|

| +15V |

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

| COM | 2k |

| INPUTS | SWITCH |

|

| |

| Located behind the wire drive |

|

|

|

|

|

|

|

|

|

|

|

| INPUTS |

|

| |||

|

|

|

|

|

|

|

|

| 4.75k |

|

| 2k |

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

| COM |

|

|

|

| ||||

|

| 1M ohms |

|

|

|

|

|

|

| 500 |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| COM |

|

|

| ||||

|

|

|

|

|

|

|

|

|

| 4.75k |

|

| 500 | 500 |

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

320V, 150J | 320V, 150J |

|

|

|

|

|

|

|

|

|

|

|

| 4.75k | 4.75k |

| For programming at LECo factory only. | ||

|

|

|

|

|

|

|

|

|

|

| +15V |

|

|

|

|

| 4.75k | 4.75k | Not field reprogrammable. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| J87 |

+Vin

J83 5

J88

PWM5

CONTROL

FOR

CONTACTOR

4.5 A PEAK CURRENT LIMIT

SPI

CKTS

J86

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

| |||

|

| welding power | ||

|

| source | ||

|

|

|

|

|

|

|

|

|

|

|

| All LED’s light | ||

|

| briefly | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Show CC/CV | ||

|

| mode and HI/LO | ||

|

| gear | ||

GAS PURGE SWITCH DEPRESSED |

|

|

|

|

| GAS PURGE SWITCH OFF | |||

|

|

|

|

|

|

|

|

|

|

Enter Press and

Spin Mode

| Idle: |

| Display WFS, |

| Wire Drive: OFF |

Gas Solenoid: OFF | |

|

|

|

|

|

|

|

| .0047/.005 mfd, |

|

|

| 5 | 6 | 7 | 8 | 9 10 11 | 13 14 15 | 1612 | 4 | 1 | 2 | 3 J85 |

|

| 1 | 2 3 4 5 6 | 7 | 8 9 10 11 12 13 14 15 | 16 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 10 |

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||

|

|

|

|

|

| 567A | 1400VDC |

|

| The contactor is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 558 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| located behind |

| 512 |

|

|

|

| 554 | 555 |

|

|

|

|

|

|

| COM | + 15V |

|

|

|

|

|

| Master In Slave Out |

| Master Out Slave In COM |

|

| ||||||

|

|

|

|

|

|

|

| Bussbar from input | the glastic panel |

|

| 559 | Gas Purge |

|

|

|

|

|

| 556 |

|

|

|

|

|

| + 5V |

| + 15 VDC SPI |

|

| Chip Select 1 | Chip Select 2 | Chip Select 3 | Serial Clock |

|

| |||||||

|

|

|

| 21 |

|

|

| next to the motor. |

|

|

| 2 Step | 2 Step |

|

|

| Trigger Supply |

| Trigger |

|

|

|

|

|

| + 5 VDC SPI | Slave Select |

|

| |||||||||||||||

|

|

|

|

|

|

| stud to contactor |

| 15 VDC | Cold Inch |

|

|

|

| Trigger Input |

|

|

|

| TRIGGER |

|

|

|

| ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 83% Input | 15 VDC when Trigger and 83% |

|

|

|

|

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Switch Open |

|

| CONNECTOR |

|

|

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| 587 | 589 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||||

| Input |

|

|

|

|

|

|

|

|

|

|

|

|

| 9 VDC when Trigger Open, 83% |

|

|

|

|

|

|

| ||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Located on the lower left |

|

| ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Switch Closed |

|

|

|

| |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0 VDC when Trigger Closed |

| of the front of the case. |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| J3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GUN |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Voltage |

|

|

|

|

|

|

| CONTACTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 556 |

| A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TRIGGER |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| 300A 60% |

|

|

|

|

|

|

|

|

|

|

|

| 554 |

| B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| 250A 100% |

|

|

|

|

| 2 Step Trigger | TRIGGER |

|

|

|

|

| C |

| INPUT |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

| Protection |

|

|

|

|

|

| Coil measures 4.4 ohms. |

|

|

|

|

| 15 VDC for 2 Step |

|

|

|

|

|

|

|

|

|

|

| 83% |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| 578 |

|

|

|

|

| 0 VDC for InterlockINTERLOCK |

|

|

|

| 555 |

| D |

| PROCEDURE |

|

|

|

| SHIELDED CABLE |

|

| ||||||||||||||

|

|

|

|

|

|

| 0 VDC Open |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| E |

|

|

|

|

| DRAIN LEAD |

|

|

|

| |||||||||

|

|

|

|

| WFS |

| 2.3 VDC Closed | 507 |

|

|

|

|

| 589 |

|

|

|

|

| 83% Procedure Input 554A |

| INPUT |

|

|

|

|

|

|

|

| ||||||||||||||

|

|

|

|

| INPUT ELECTRODE |

| 12 VDC coil |

|

|

|

|

|

|

|

|

|

|

| S2 | 0 VDC Normal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

| CABLE CONNECTION |

| PWM Controlled |

|

|

|

|

|

| 587 |

|

|

|

|

| 9 VDC 83% switch Closed |

| The 83% procedure reduces the |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| and Trigger Open |

| WFS to 83% of the set point, but |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

| WORK |

|

| Control |

|

|

|

|

|

|

| Gas Purge |

|

|

|

|

|

|

|

|

|

|

| no less than 50 in/min. It is used |

|

|

|

|

|

|

|

|

|

| N.A. |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| most often when pipe welding. |

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

| CLIP |

|

|

|

|

|

|

|

|

| 15 VDC when Purge OFF | COLD INCH/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 0 VDC when Purge ON | GAS PURGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| Circuit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 10 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 558 (BLK) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| J1 |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| S1 |

|

|

|

|

|

|

|

|

|

| DISPLAY P.C. BOARD |

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 512 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Schematic |

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 559 (RED) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

N.A. CAVITY NUMBERING SEQUENCE AS VIEWED FROM COMPONENT SIDE OF BOARD. |

|

|

|

|

|

|

|

|

|

|

| Cold Inch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| Contactor |

|

|

|

|

| 15 VDC when Inch OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

N.B. CAVITY NUMBERING SEQUENCE AS VIEWED FROM LEAD SIDE OF CONNECTOR. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

| 0 VDC when Inch ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

N.C. TOGGLE SWITCHES AND POTENTIOMETERS SHOWN FROM CONNECTION SIDE OF SWITCH. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Model | Ranger 8,9 | Classic | Ranger 250, 305 | V350 | Square Wave TIG | Miller Inverters | STT II | Note: | Interlock |

|

|

|

|

|

|

|

|

|

|

|

| Gun Trigger |

|

|

|

| Display |

|

| |||||||||||||||

|

|

| Commander 300,400,500 | (Common Digital |

| 300/355 |

|

| Most semiautomatic | Circuit |

|

|

|

|

|

|

|

|

|

|

|

| Circuit |

|

|

|

|

|

|

|

| Board |

|

| ||||||||||

|

|

| (Common Analog | Controls) |

|

|

|

| wire welding | Inch/Purge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||

|

|

| Controls) |

|

|

|

|

| processes perform |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||

Recommended | Recommended for CV | Recommended for CV | Recommended for | Recommended | Not recommended | Recommende | Not | better using constant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Circuit |

|

| |||||||||||||||

the Arc | all CV operation. | operation. (Wire | operation. | CV operation. | for CV and CC | for CC operation | d for CV | recommended | voltage power sources. |

|

| Circuit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||

|

| Feed Module |

|

| operation. | because the | voltage sense | for STT | Be sure the proper |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

| Required) |

|

|

| customer may | operation. | operation. | power source is used |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

| experience short |

|

| for your application. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| contactor life from |

|

| Contactor life may be |

|

|

|

|

|

|

|

|

|

|

| THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED |

| ||||||||||||||||||||||

|

|

|

|

|

| inductive nature of |

|

| shortened in |

|

| PROPRIETARY & CONFIDENTIAL: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC. |

|

| |||||||||||||||||||||||

|

|

|

|

|

| the power source. |

|

| applications using CC |

|

| UNLESS OTHERWISE SPECIFIED TOLERANCE | DESIGN INFORMATION |

| REFERENCE: | EQUIPMENT TYPE: |

|

|

|

| PAGE 1 | OF 1 |

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

| machines with high |

|

| MANUFACTURING TOLERANCE PER E2056 |

|

|

|

|

|

|

|

|

|

|

| EDGE | ||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

| ON 2 PLACE DECIMALS IS ± .02 |

|

|

|

|

|

|

| G4198 |

|

|

|

| |||||||||||||||||||||

|

|

|

|

|

|

|

|

| OCV. |

|

| ON 3 PLACE DECIMALS IS ± .002 |

| DRAWN BY: E. ENYEDY/KJ |

| SUBJECT: |

|

|

| MACHINE SCHEMATIC |

|

|

| DOCUMENT | DOCUMENT | |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

| ON ALL ANGLES IS ± .5 OF A DEGREE |

|

|

|

|

|

|

|

|

|

|

|

|

|

| NUMBER: | REVISION: | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| ENGINEER: | E. ENYEDY | SCALE: |

|

|

|

|

|

|

| |||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

| MATERIAL TOLERANCE ("t ") TO AGREE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| A | SOLID | ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| WITH PUBLISHED STANDARDS. |

|

|

|

|

|

|

|

| MATERIAL |

| APPROVAL |

| PROJECT | CRM35166 |

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| DO NOT SCALE THIS DRAWING | APPROVED: |

|

|

|

| NONE |

| DISPOSITION: | NA | DATE: | 05/27/2003 | NUMBER: |

|

|

|

| ||||||||||||||||

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.