Ranger 10,000 /10,000 Plus

For Engine

Safety

Powered equipment

ARC Rays can burn

Fumes and Gases

Iii

Welding and Cutting Sparks can cause fire or Explosion

Cylinder may explode If damaged

Précautions DE Sûreté

Master Table of Contents for ALL Sections

Section A-1

Table of Contents

Installation Section

Installation

Height Width Depth Weight

Horsepower Operating Speed RPM

Machine Grounding

Safety Precautions

Spark Arrester

Towing

Vehicle Mounting

PRE-OPERATION Service

Gasoline

Can cause fire or explosion

Angle of Operation

Welding Output Cables

Total Combined Length of Electrode and Work Cables

Lifting

Stacking

Connection of Lincoln Electric Wire Feeders

Instructions

Welder Operation

Duplex Receptacles

Auxiliary Power

120/240 Volt Dual Voltage Receptacle

Motor Starting

These Devices Without Additional Resistive Type Loads

Not USE These Devices With a Ranger 10,000

Simultaneous Welding and Power

Standby Power Connections

Figure A.1

Ranger 10,000 & Ranger 10,000 Plus

Operation

Operation Section

Section B-1

Welder Controls Function and Operation

Engine Switch

Operation

Kohler Honda Robin / Subaru 20 H.P. Command

Polarity Switch

Range Switch

Control Dial

Starting the Engine

STARTING/SHUTDOWN Instructions

BREAK-IN Period

Stopping the Engine

TIG Constant Current Welding

Wire Feed Welding Processes Constant Voltage

Stick Constant Current Welding

Start Switch Wire FEED, LN-15

Summary of Welding Processes

Accessories Section

Section C-1

Accessories

Optional Equipment Field Installed

TIG Welding

Recommended Equipment

Stick

Plasma Cutting

Ranger 10,000 & Ranger 10,000 Plus

Maintenance Section

Section D-1

Kohler Honda

Maintenance

Safety Precautions

AIR Cleaner and Other Maintenance

OIL Filter Change

Overspeed is Hazardous

Engine Adjustments

Battery

Slip Rings

Air Filter

Pre-Cleaner

Oil Filter

Element

Figure D.1 Major Component Location

Theory of Operation

Theory of Operation Section

Section E-1

BATTERY, STARTER, ENGINE, ROTOR, STATOR, and Idler Solenoid

Theory of Operation

Rotor Field Feedback and Auxiliary Power

Figure E.3 Rotor Field Feedback and Auxiliary Power

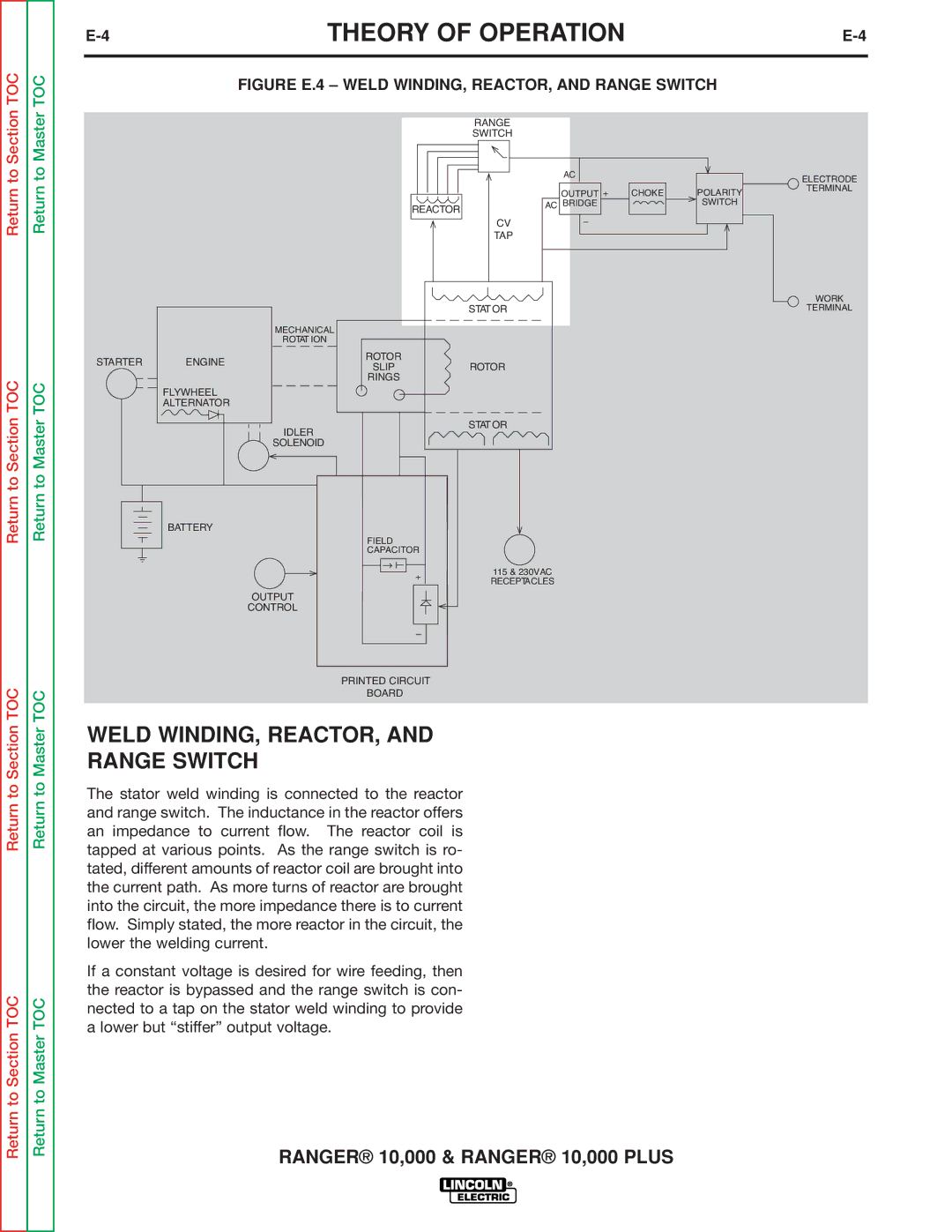

Weld WINDING, REACTOR, Range Switch

Figure E.4 Weld WINDING, REACTOR, and Range Switch

Output BRIDGE, Choke Polarity SWITCH, and Output Terminals

Ranger 10,000 & Ranger 10,000 Plus

Troubleshooting & Repair Section

Section F-1

Troubleshooting & Repair

HOW to USE Troubleshooting Guide

PC Board Troubleshooting Procedures

Electric Shock

Troubleshooting Guide

Output Problems

Output Problems

Field Winding Voltage Test

Adjustment Test

Troubleshooting Guide

Output Problems

Engine Problems

Make sure the leads are looped

Charging Circuit Test

Welding Problems

Ranger 10,000 & Ranger 10,000 Plus

Materials Needed

Rotor Voltage Test

Test Description

Test Procedure

Rotor Resistance Test

Rotor Resistance Test

Figure F.2 Location of Rotor Slip Rings

Troubleshooting & Repair

Ranger 10,000 & Ranger 10,000 Plus

Auxiliary and Field Winding Test

To test the 230 VAC winding

Auxiliary and Field Winding Test

To test the 115 VAC winding

To test the field winding

Ranger 10,000 & Ranger 10,000 Plus

Output Rectifier Bridge Test

Figutpure F.4 Locationctifof Output Rectifier Leads

26TROUBLESHOOTING & REPAIRF-26

Output Rectifier Bridge Test

Charging Circuit Test

Charging Circuit Test

Figure F.5 Location of Voltage Regulator

Engine Throttle Adjustment Test

Engine Throttle Adjustment Test

Figure F.6 Blower Paddle Marked for STROBE-TACH Method

Figure F.7

Oscilloscope Method

High Idle no Load Output Control AT Maximum

Scope Settings

Normal Open Circuit Voltage Waveform 115 VAC Supply

Machine Loaded to 200 Amps AT 20 VDC

Typical DC Weld Output Waveform CV Mode

Machine Loaded

Typical DC Weld Output Waveform CC Mode

Machine Loaded to 200 Amps AT 26 VDC

Typical AC Weld Output Waveform

Machine Loaded to 225 Amps AT 25 VDC

Abnormal Open Circuit Weld Voltage Waveform CV Mode

Abnormal Open Circuit DC Weld Voltage Waveform

Normal Open Circuit Weld Voltage Waveform CV Mode

Normal Open Circuit DC Weld Voltage Waveform CC Mode

Normal Open Circuit AC Weld Voltage Waveform

Ranger 10,000 & Ranger 10,000 Plus

Brush Removal and Replacement

Description

Brush Removal and Replacement

Procedure

Slip Rings

Figure F.9 Brush LEADS/BRUSHES Retained with Cable TIE

Ranger 10,000 & Ranger 10,000 Plus

Printed Circuit Board Removal Replacement

Printed Circuit Board Removal and Replacement

Figure F.10 Printed Circuit Board Location

Replacement

Printed Circuit Board Removal

Ranger 10,000 & Ranger 10,000 Plus

Output Rectifier Bridge Removal Replacement

Remove the case top, then reinstall the fuel cap

Output Rectifier Bridge Removal

Section TOC

Ranger 10,000 & Ranger 10,000 Plus

ENGINE/ROTOR Removal and Replacement

Instructions

ENGINE/ROTOR Removal

Figure F.12 Component LOCATIONS, ENGINE/ROTOR Removal

Engine and Rotor Removal Procedure

Rotor Removal Procedure

Figure F.13 Engine and Rotor Removed from Stator THRU-BOLT

Replacement KIT S20788

Reassembly Procedure

Retest After Repair

Section G-1

Electrical Diagrams Section

Electrical Diagrams

Electrical Diagrams

Wiring Diagram Code 11041 only -M20226

Wiring Diagram Code 11095 only M20301

Ranger 10,000 Honda

Ranger 10,000

Wiring Diagram Code 11398 M21269

Ranger 10,000 Plus

Schematic Entire Machine Codes 11395 and 11398 L13105

L13105

Schematic Entire Machine CDE 11394 L13103

L13103

Schematic Entire Machine Code 11095 & 11253 only L12257

Schematic Entire Machine Code 11151 only L12249-1

L12249

Electrical Diagrams

Electrical Diagrams