Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

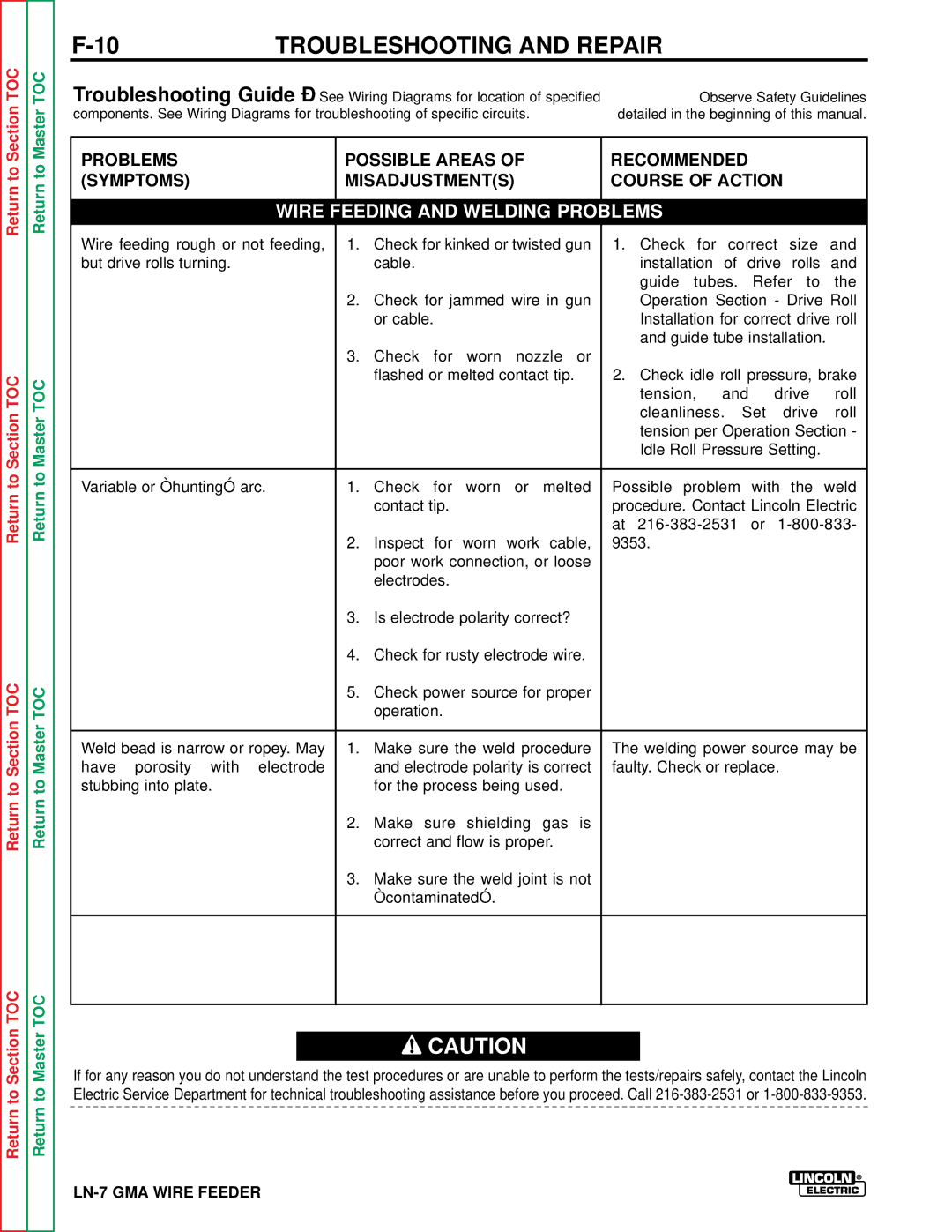

TROUBLESHOOTING AND REPAIR |

|

| ||||

Troubleshooting Guide – See Wiring Diagrams for location of specified | Observe Safety Guidelines | |||||

components. See Wiring Diagrams for troubleshooting of specific circuits. | detailed in the beginning of this manual. | |||||

|

|

|

|

|

| |

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| |

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| ||

|

|

|

|

|

| |

| WIRE FEEDING AND WELDING PROBLEMS |

|

| |||

Wire feeding rough or not feeding, | 1. | Check for kinked or twisted gun | 1. Check for correct size and | |||

but drive rolls turning. |

|

| cable. | installation of drive rolls and | ||

|

|

|

| guide tubes. Refer to the | ||

|

| 2. | Check for jammed wire in gun | Operation Section - Drive Roll | ||

|

|

| or cable. | Installation for correct drive roll | ||

|

|

|

| and guide tube installation. |

| |

|

| 3. | Check for worn nozzle or |

|

|

|

|

|

| flashed or melted contact tip. | 2. Check idle roll pressure, brake | ||

|

|

|

| tension, and | drive | roll |

|

|

|

| cleanliness. Set | drive | roll |

|

|

|

| tension per Operation Section - | ||

|

|

|

| Idle Roll Pressure Setting. |

| |

|

|

|

| |||

Variable or “hunting” arc. | 1. | Check for worn or melted | Possible problem with the weld | |||

|

|

| contact tip. | procedure. Contact Lincoln Electric | ||

|

|

|

| at | ||

|

| 2. | Inspect for worn work cable, | 9353. |

|

|

|

|

| poor work connection, or loose |

|

|

|

|

|

| electrodes. |

|

|

|

|

| 3. | Is electrode polarity correct? |

|

|

|

|

| 4. | Check for rusty electrode wire. |

|

|

|

|

| 5. | Check power source for proper |

|

|

|

|

|

| operation. |

|

|

|

|

|

|

| |||

Weld bead is narrow or ropey. May | 1. | Make sure the weld procedure | The welding power source may be | |||

have porosity with | electrode |

| and electrode polarity is correct | faulty. Check or replace. |

| |

stubbing into plate. |

|

| for the process being used. |

|

|

|

|

| 2. | Make sure shielding gas is |

|

|

|

|

|

| correct and flow is proper. |

|

|

|

|

| 3. | Make sure the weld joint is not |

|

|

|

|

|

| “contaminated”. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call