Return to Section TOC

Section TOC

Return to Master TOC

Master TOC

TROUBLESHOOTING AND REPAIR |

CONTROL RELAY TEST (continued)

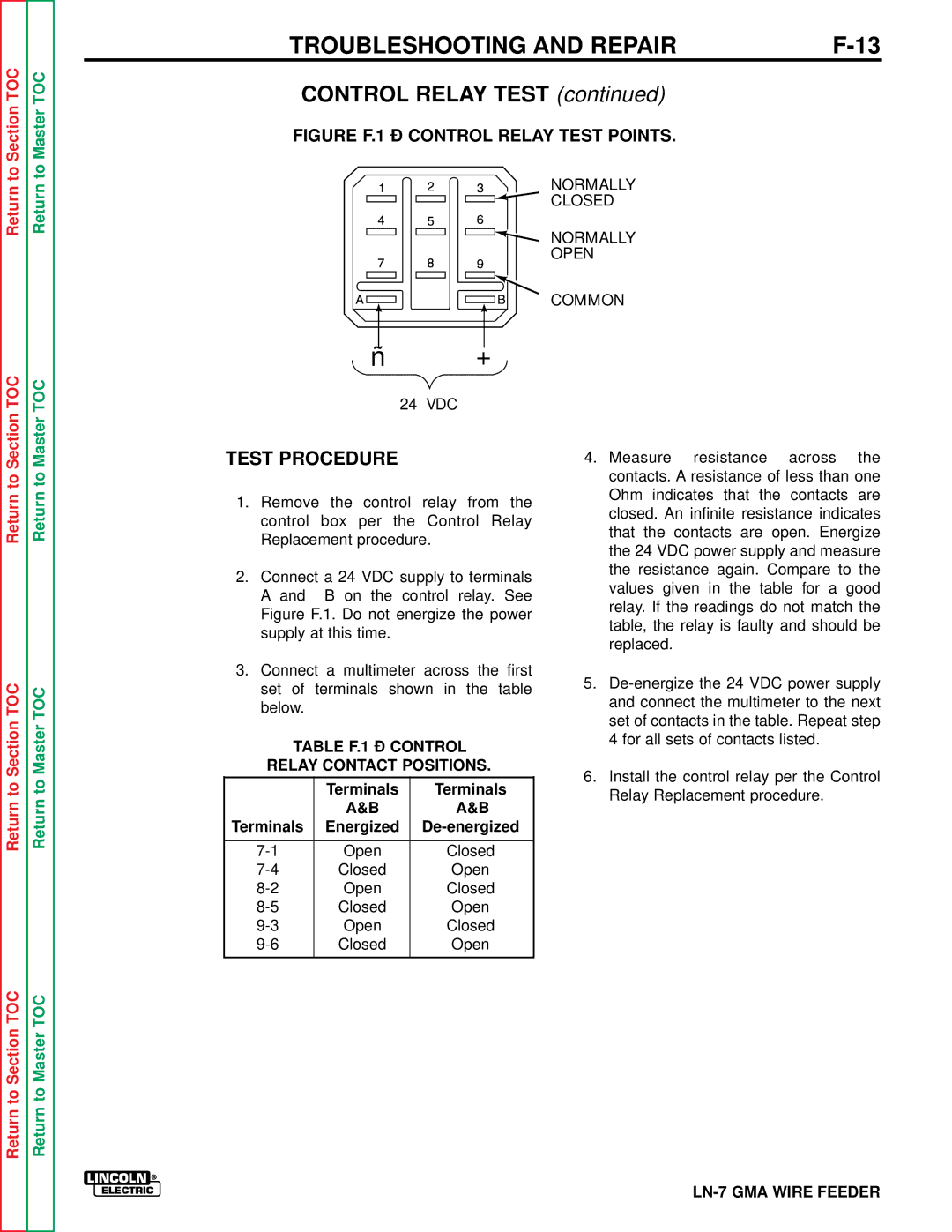

FIGURE F.1 – CONTROL RELAY TEST POINTS.

NORMALLY

CLOSED

NORMALLY

OPEN

COMMON

–+

24 VDC

Return to

Return to Master TOC

Return to Master TOC

TEST PROCEDURE

1.Remove the control relay from the control box per the Control Relay Replacement procedure.

2.Connect a 24 VDC supply to terminals A and B on the control relay. See Figure F.1. Do not energize the power supply at this time.

3.Connect a multimeter across the first set of terminals shown in the table below.

TABLE F.1 – CONTROL

RELAY CONTACT POSITIONS.

| Terminals | Terminals |

| A&B | A&B |

Terminals | Energized | |

|

|

|

Open | Closed | |

Closed | Open | |

Open | Closed | |

Closed | Open | |

Open | Closed | |

Closed | Open | |

|

|

|

4.Measure resistance across the contacts. A resistance of less than one Ohm indicates that the contacts are closed. An infinite resistance indicates that the contacts are open. Energize the 24 VDC power supply and measure the resistance again. Compare to the values given in the table for a good relay. If the readings do not match the table, the relay is faulty and should be replaced.

5.

6.Install the control relay per the Control Relay Replacement procedure.