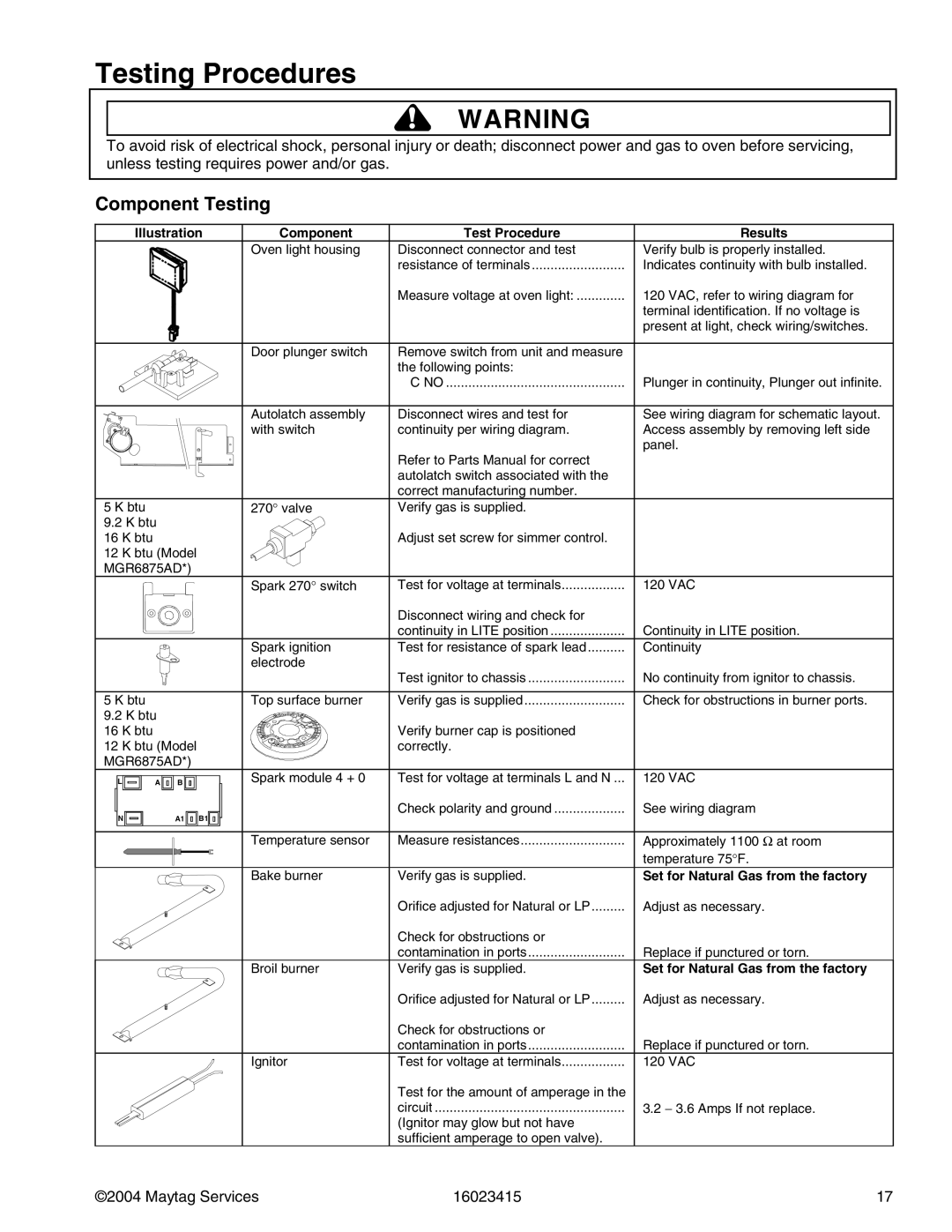

Testing Procedures

!WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas.

Component Testing

Illustration | Component | Test Procedure | Results | ||

|

|

| Oven light housing | Disconnect connector and test | Verify bulb is properly installed. |

|

|

|

| resistance of terminals | Indicates continuity with bulb installed. |

|

|

|

| Measure voltage at oven light: | 120 VAC, refer to wiring diagram for |

|

|

|

|

| terminal identification. If no voltage is |

|

|

|

|

| present at light, check wiring/switches. |

|

|

| Door plunger switch | Remove switch from unit and measure |

|

|

|

|

| the following points: |

|

|

|

|

| C NO | Plunger in continuity, Plunger out infinite. |

|

|

| Autolatch assembly | Disconnect wires and test for | See wiring diagram for schematic layout. |

|

|

| with switch | continuity per wiring diagram. | Access assembly by removing left side |

|

|

|

|

| panel. |

|

|

|

| Refer to Parts Manual for correct |

|

|

|

|

| autolatch switch associated with the |

|

|

|

|

| correct manufacturing number. |

|

5 K btu |

|

| 270° valve | Verify gas is supplied. |

|

9.2 K btu |

|

|

|

| |

16 K btu |

|

|

| Adjust set screw for simmer control. |

|

12 K btu (Model |

|

|

| ||

MGR6875AD*) |

|

|

| ||

|

|

| Spark 270° switch | Test for voltage at terminals | 120 VAC |

|

|

|

| Disconnect wiring and check for |

|

|

|

|

| continuity in LITE position | Continuity in LITE position. |

|

|

| Spark ignition | Test for resistance of spark lead | Continuity |

|

|

| electrode |

|

|

|

|

|

| Test ignitor to chassis | No continuity from ignitor to chassis. |

5 K btu |

|

| Top surface burner | Verify gas is supplied | Check for obstructions in burner ports. |

9.2 K btu |

|

|

|

| |

16 K btu |

|

|

| Verify burner cap is positioned |

|

12 K btu (Model |

| correctly. |

| ||

MGR6875AD*) |

|

|

| ||

L | A | B | Spark module 4 + 0 | Test for voltage at terminals L and N ... | 120 VAC |

N |

| A1 B1 |

| Check polarity and ground | See wiring diagram |

|

|

|

| ||

|

|

| Temperature sensor | Measure resistances | Approximately 1100 Ω at room |

|

|

|

|

| temperature 75°F. |

|

|

| Bake burner | Verify gas is supplied. | Set for Natural Gas from the factory |

|

|

|

| Orifice adjusted for Natural or LP | Adjust as necessary. |

|

|

|

| Check for obstructions or |

|

|

|

|

| contamination in ports | Replace if punctured or torn. |

|

|

| Broil burner | Verify gas is supplied. | Set for Natural Gas from the factory |

|

|

|

| Orifice adjusted for Natural or LP | Adjust as necessary. |

|

|

|

| Check for obstructions or |

|

|

|

|

| contamination in ports | Replace if punctured or torn. |

|

|

| Ignitor | Test for voltage at terminals | 120 VAC |

|

|

|

| Test for the amount of amperage in the |

|

|

|

|

| circuit | 3.2 − 3.6 Amps If not replace. |

|

|

|

| (Ignitor may glow but not have |

|

|

|

|

| sufficient amperage to open valve). |

|

©2004 Maytag Services | 16023415 | 17 |